While forklifts do work well for lifting and moving heavy loads indoors, they're bulky (in close quarters), expensive, and can't lift loads over a certain footprint size. That's where the FORMIC modular robotic transportation system is designed to come in.

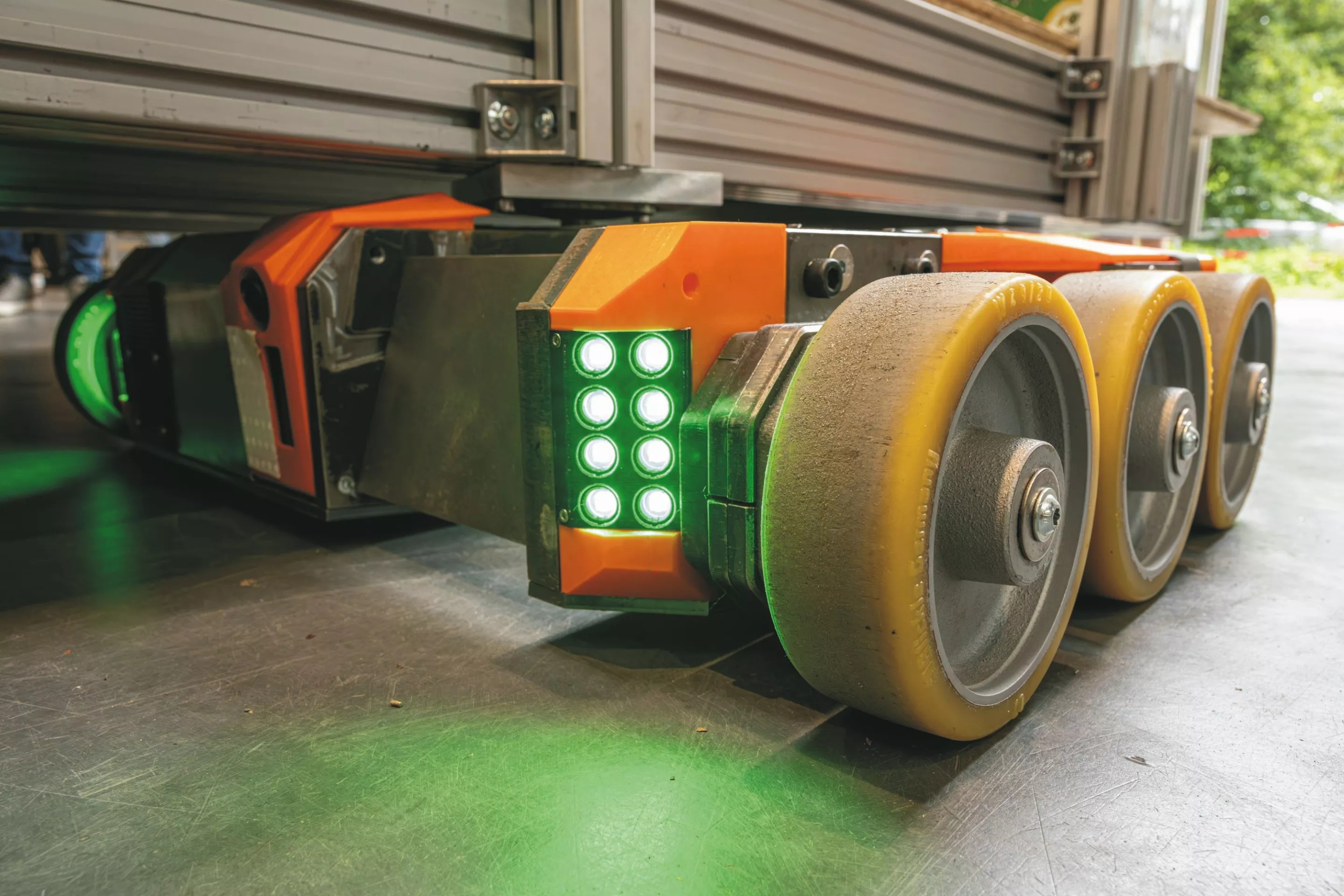

The technology is being developed by German startup FORMIC Transportsysteme, which is affiliated with the Karlsruhe Institute of Technology. It incorporates multiple six-wheeled robotic transport modules, each one of which is equipped with cameras, a radio communications chip, and a jack that is capable of lifting up to 2.5 tons (2.3 tonnes).

As many as 15 of the modules can be placed under a single load, as long as there's a sufficient vertical gap beneath it for them to squeeze in. If all 15 are used, they can manage a total load weight of 37.5 tons (34 tonnes).

A human operator steers the swarm of robotic modules in real time via an included joystick remote. Because the modules' cameras and radios allow them to track one another's positions at all times, they autonomously coordinate their movements – so in other words, the user just controls them as a group, not as individual units.

An official commercial launch of the FORMIC system should take place later this year. The modules can be seen in action, in the video below.

Sources: Karlsruhe Institute of Technology, FORMIC Transportsysteme