Although optical fibers are highly effective at data transmission, they're also relatively brittle. An experimental new type of optical fiber addresses that limitation, by incorporating a core made of liquid glycerol.

Ordinarily, optical fibers are made of either solid glass or a solid transparent plastic. The former is able to carry light pulses over a longer distance, but will break fairly easily if bent or stretched. The latter – which is useful over shorter distances, such as within buildings – stands up better to bending, but stretching it will still cause it to break.

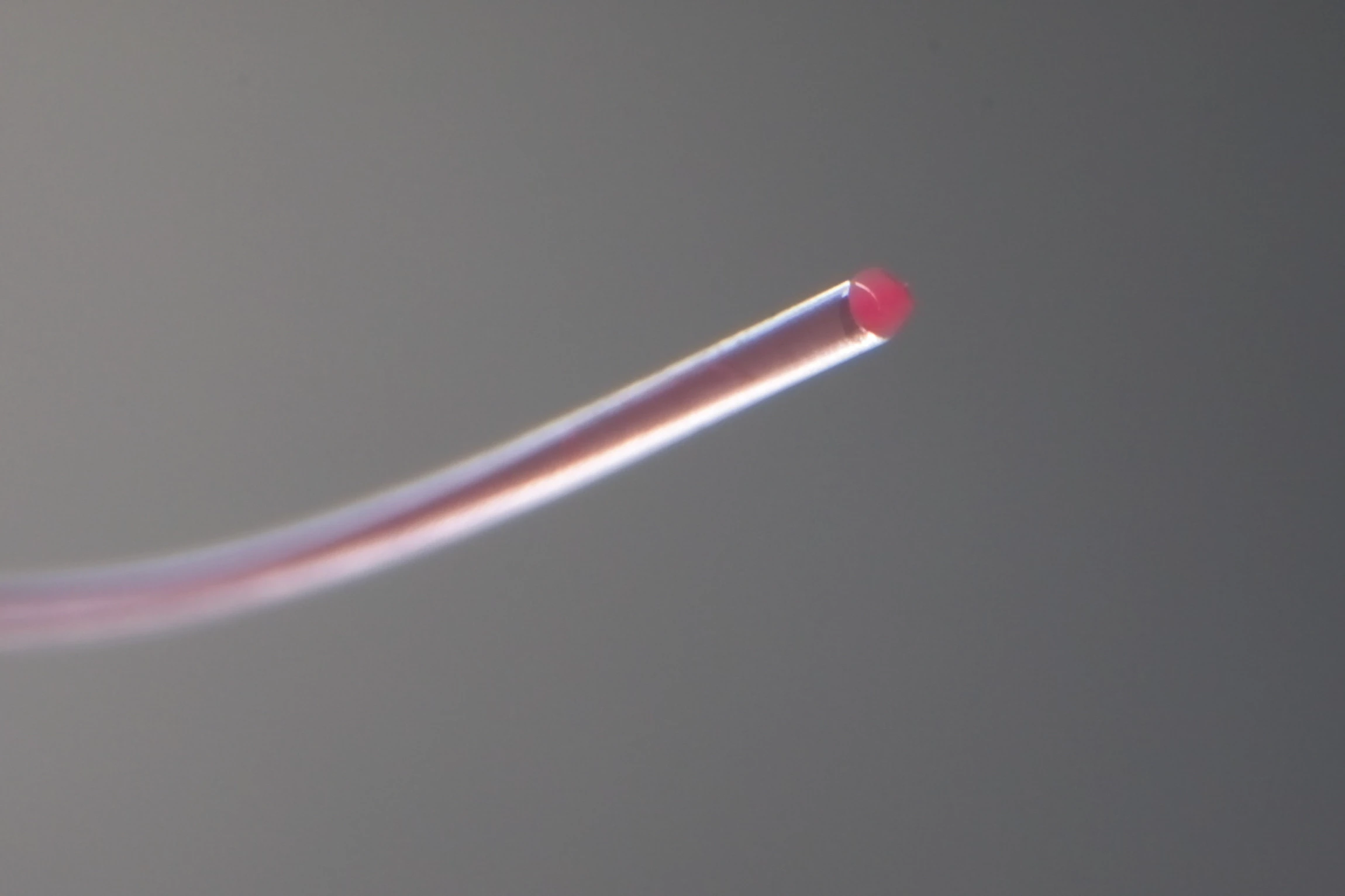

Seeking an alternative, researchers at Switzerland's Empa institute have developed an optical fiber consisting of a continuous liquid glycerol core contained within a transparent fluoropolymer sheath.

"The two components of the fiber must pass through our spinneret together under high pressure and at 200 to 300 degrees Celsius [392 to 572 ºF]," says the lead scientist, Dr. Rudolf Hufenus. "So we need a liquid with a suitable refractive index for functionality and with the lowest possible vapor pressure to produce the fiber."

The resulting fiber's ability to transmit data in the form of light pulses is approximately equal to that of solid plastic optical fibers, but it has much higher tensile strength – in other words, it's significantly better at withstanding stretching.

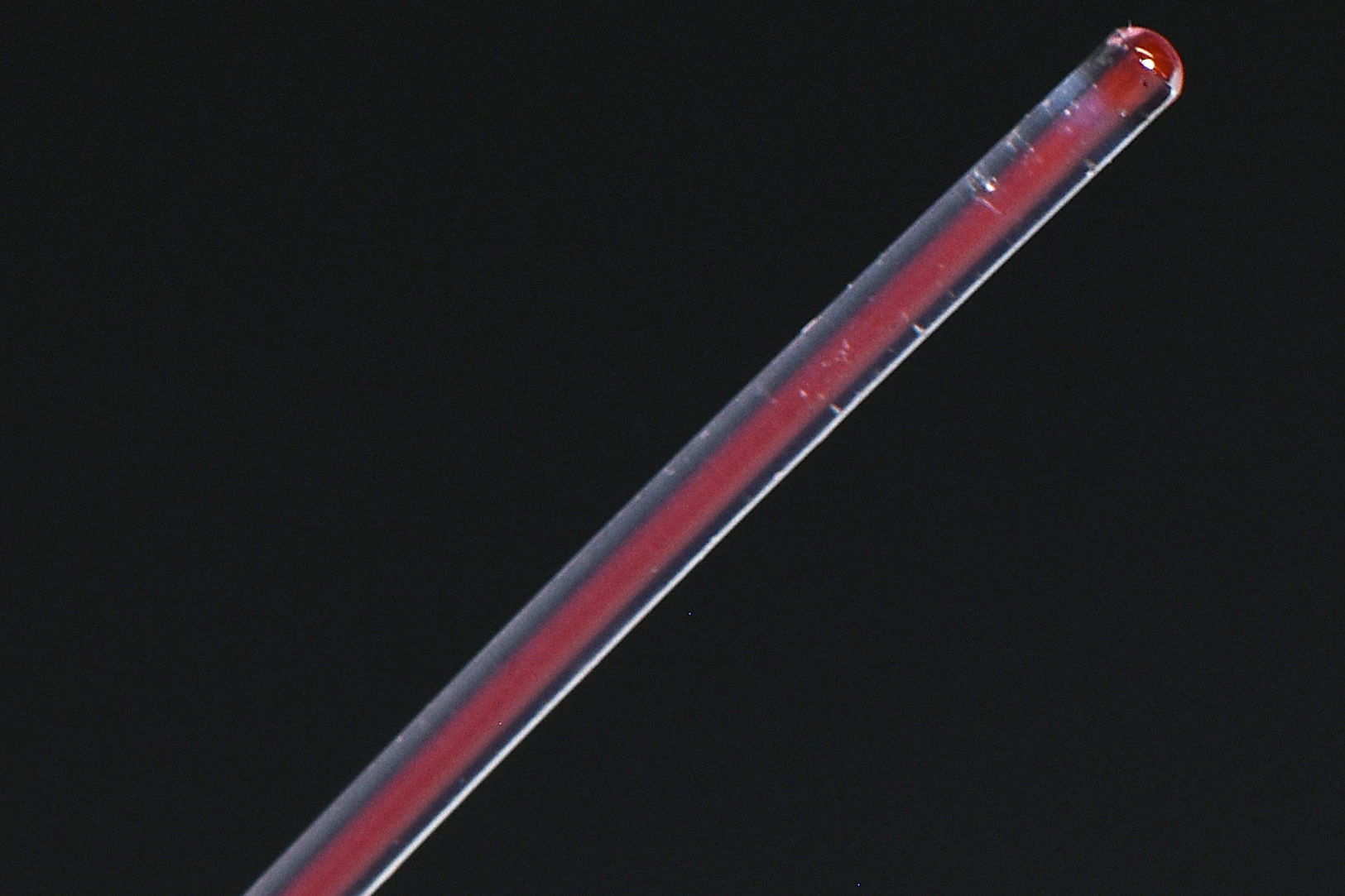

As an added bonus, if the fiber is being stretched, its color will change. This is due to the fact that the same amount of glycerol will still be present within the fiber, but because the liquid is being spread out over a longer distance, red dye particles within it will be farther apart from one another. As a result, the color of the light that's emitted through the sheath will subtly change. That color-change could be measured using an optical sensor, letting users know that the fiber – and thus a device incorporating it – is lengthening or being subjected to a tensile load.

All of that being said, won't the glycerol just leak out when the fiber is cut to the desired length? "Under normal conditions, the liquid core is kept inside the fiber due to capillary forces; however, when a pressure is applied on the fiber, the liquid can be pressed out of the fiber tip," Hufenus tells us. "This can be prevented by sealing the fiber end with a hot blade."

Ultimately, it is hoped that the fiber will find use not only in less fragile data transmission, but also for force transmission in micromotors or microhydraulic systems.

Source: Empa