While thin sheets of lab-grown biological tissue do show promise for applications such as the treatment of wounds, picking those delicate sheets up can be very difficult. That's where a new octopus-inspired gripper is designed to come in.

Currently, if someone tries using a device such as a pair of tweezers to lift a biotissue sheet out of the culture in which it was grown, that fragile sheet is likely to rip or irreversibly crumple in upon itself.

One alternative involves growing a sheet of the tissue on a temperature-sensitive soft polymer, which is transplanted onto the wound site along with that sheet. As the polymer subsequently warms up, it shrinks, and thus releases the tissue sheet. Unfortunately, though, transferring a single sheet via this process reportedly takes 30 minutes to an hour, and the sheet may still end up getting damaged.

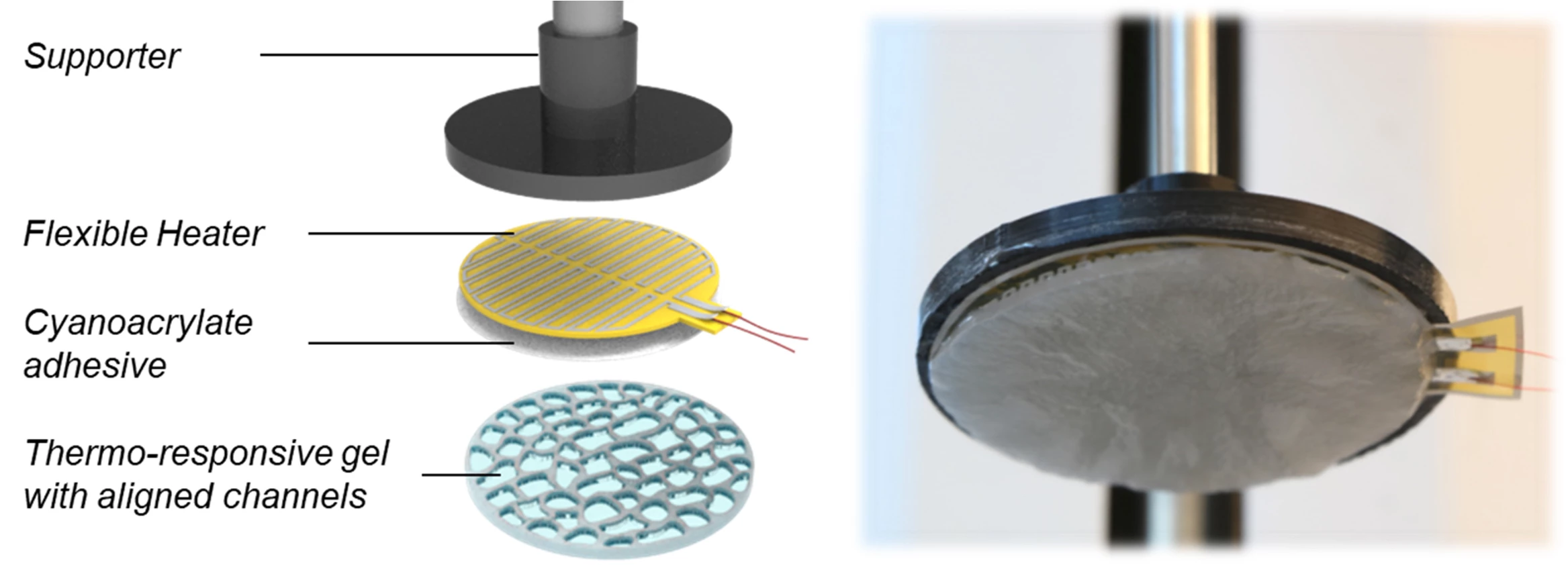

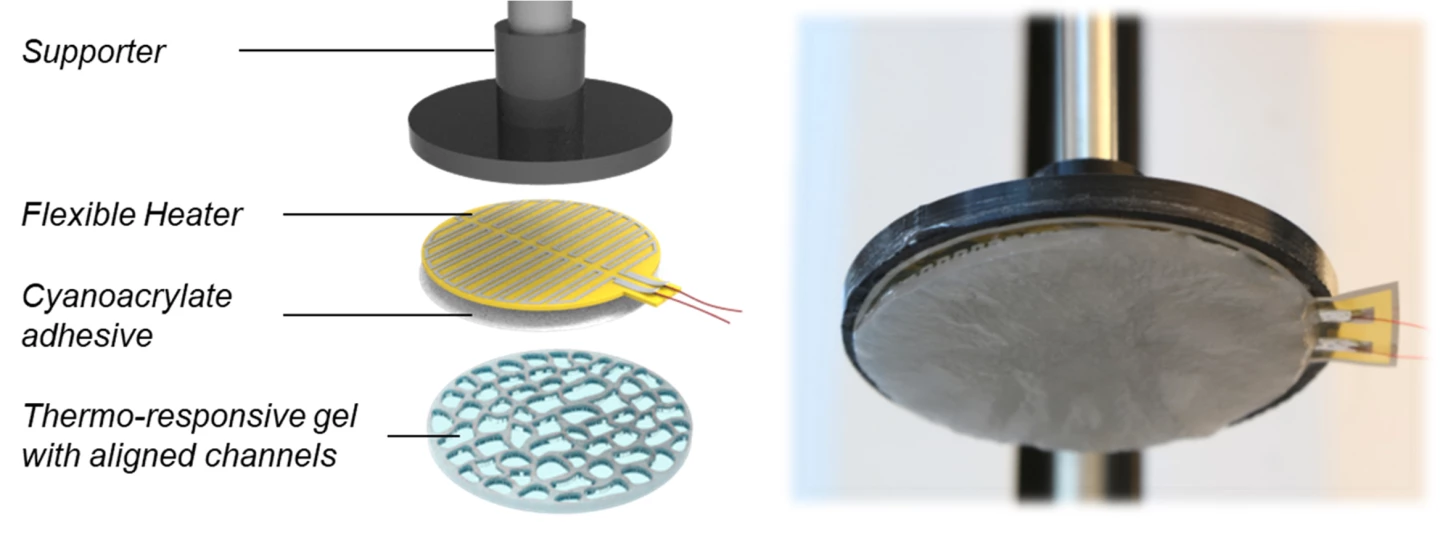

Instead, an international team of scientists looked to the manner in which octopi are able to grasp items utilizing pressure changes in their tentacles' suction cups. This led the researchers to develop a prototype device that incorporates a layer of temperature-sensitive hydrogel attached to an electric heater.

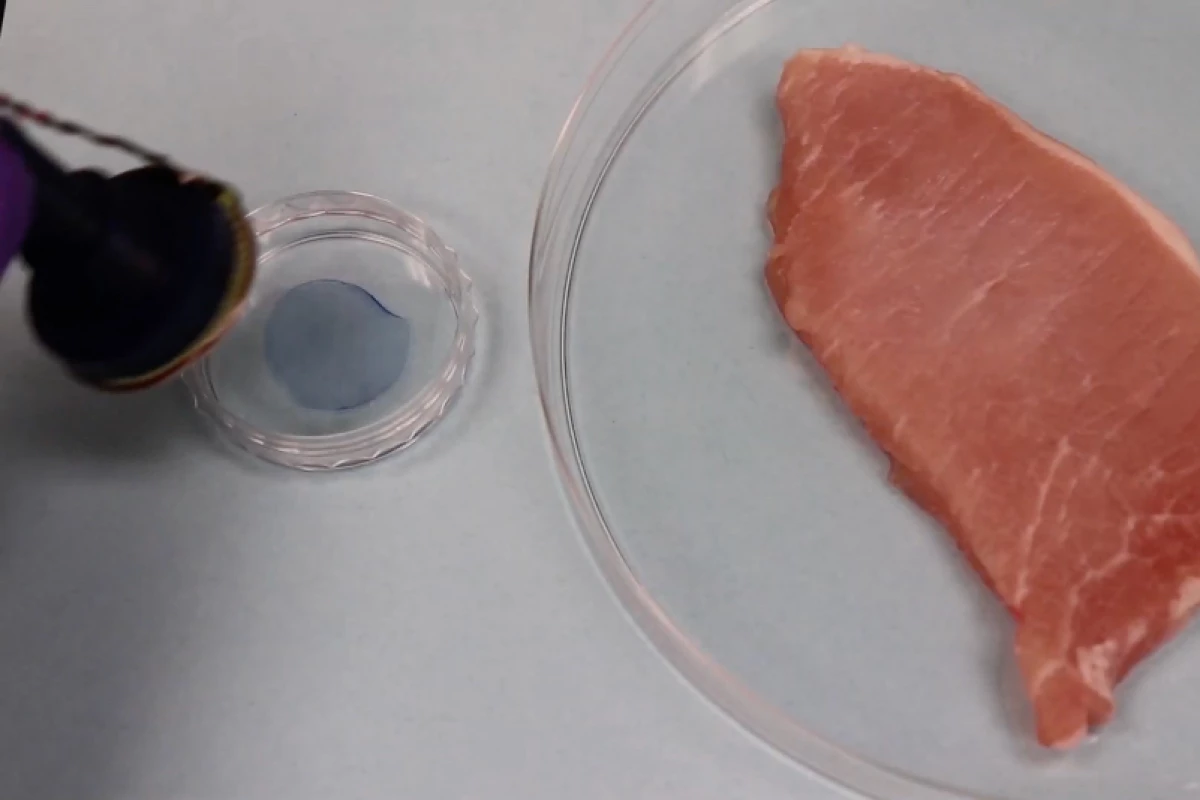

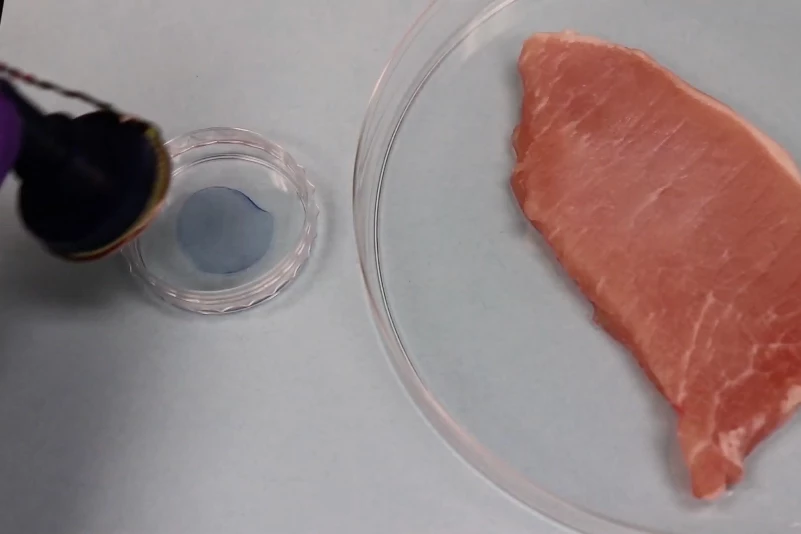

In order to pick a biotissue sheet up, the heater is first used to warm the gel, causing it to shrink. The gel is then lightly pressed against the sheet, and the heater is turned off. This causes the gel to expand back to its original state, gently creating suction against the sheet as it does so. After the sheet has subsequently been lifted from the culture and transferred to the wound site, the gel is heated again. This once again causes it to shrink, thereby releasing the sheet.

The whole process takes only about 10 seconds, and plans call for the device to be further improved.

"By integrating pressure sensors with the manipulator, it would be possible to monitor the deformation of target objects during contact and, in turn, adjust the suction force to a level at which materials retain their structural integrity and functionality," says study leader Prof. Hyunjoon Kong, from the University of Illinois at Urbana-Champaign. "By doing so, we can improve the safety and accuracy of handling these materials."

A paper on the research – which also involves scientists from Purdue University, the University of Illinois at Chicago, Korea's Chung-Ang University, and the Korea Advanced Institute for Science and Technology – was recently published in the journal Science Advances.

The gripper can be seen in action, in the following video.

Source: University of Illinois at Urbana-Champaign