When plants perform movements, such as curling their leaves or twisting their stems, they do so by drawing water into the cellulose fibers in that part of their "body." Scientists have now replicated that technique to produce self-folding paper structures.

Like plants, paper is made up mostly of cellulose fibers. In both cases, when those fibers absorb water, they expand. If a lot of the fibers expand in the same area – at the same time and at the same rate – it causes the material to bend.

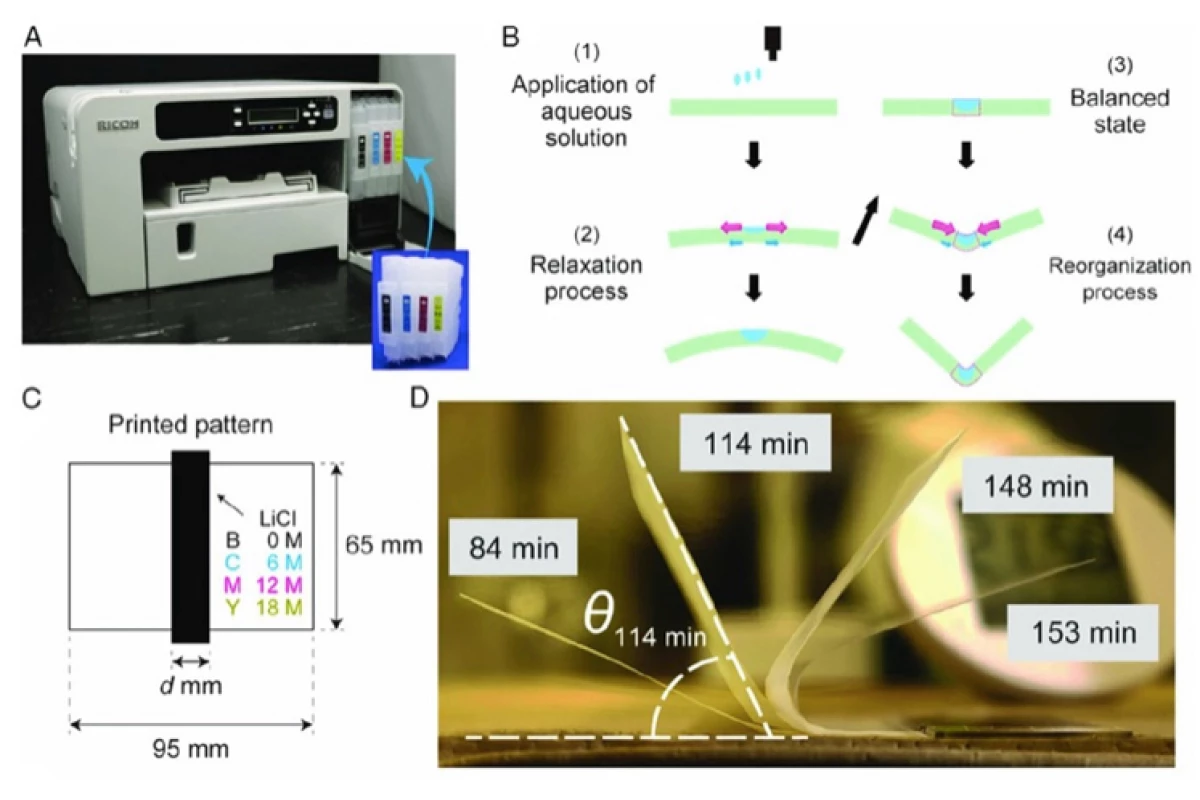

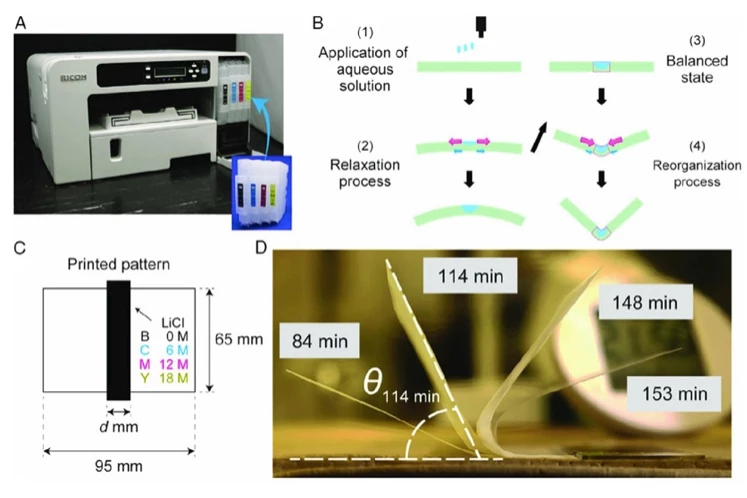

With that in mind, researchers from Japan's Shibaura Institute of Technology and Waseda University started by modifying an existing inkjet printer. More specifically, they substituted the black, magenta, yellow and cyan inks in its four ink cartridges with an aqueous solution. That liquid consisted of a mix of water and lithium chloride salt – the concentration of salt within the water differed between each cartridge.

When lines of the solution were printed onto a sheet of paper, the swelling and subsequent drying/contracting of the cellulose fibers caused that paper to permanently fold along those lines. The speed at which it folded, however, depended on the salt concentration. Whereas pure water caused the paper to fold quickly, progressively higher concentrations of lithium chloride correspondingly delayed the process.

Thereby, by selectively printing different lines from different cartridges, it was possible to get the paper to fold first along some lines, then later along others. In this fashion, the scientists were able to create items such as a self-folding paper airplane.

If combined with an existing technique for printing electrical circuits onto materials including paper, the technology could be put to some valuable uses.

"By merging these two technologies, we will realize a rapid yet simple fabrication procedure for mechatronic elements and paper robots," says Waseda University's Dr. Shuji Hashimoto. "It would find applications in the space, healthcare, and agriculture fields, where tailor-made and disposable intelligent devices are needed."

A paper on the research was recently published in the journal Advanced Intelligent Systems.

Source: Shibaura Institute of Technology