If the inner socket of a prosthetic leg doesn't conform to the contours of the user's leg stump, considerable pain and even skin ulcers may result. A new prosthesis should help keep that from happening, by automatically pumping up its socket to maintain a good fit.

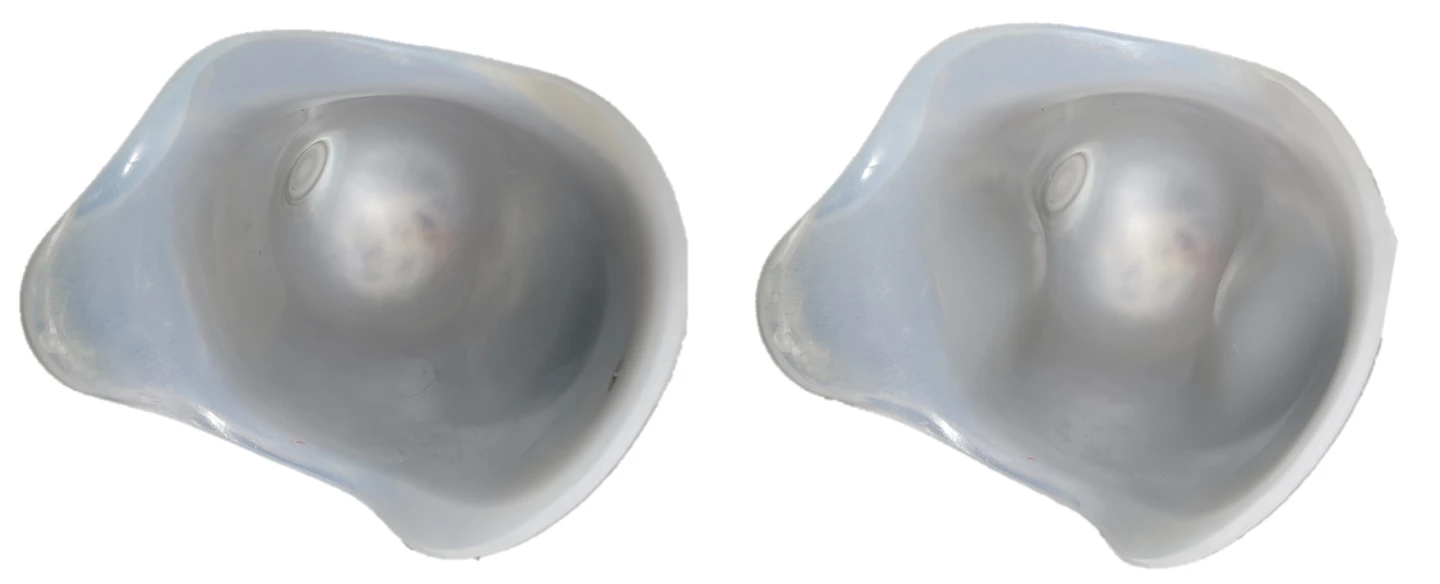

Developed by scientists at the Korea Institute of Machinery and Materials, the prototype device is designed to be utilized by people with above-the-knee amputations. It features a carbon fiber outer shell and an inflatable elastomer lining in its socket, along with an externally mounted electric pump. That pump is connected to the lining, and is controlled by an AI-based algorithm.

As the user walks, integrated sensors detect changes in the pressure exerted by the stump on the socket. That pressure may change multiple times throughout the day, due to variations in blood circulation and other factors.

If the sensors detect any empty space within the socket – which would allow the stump to move around relative to it – the algorithm responds by activating the pump to inflate the socket lining in those areas.

As a result, a firm but not too-firm fit is maintained at all times. The algorithm can additionally tweak the pressure in response to changes in the user's detected walking gait, plus the user can take manual control of the pressure via an accompanying app.

Senior researcher Lee Kang-ho and colleagues are now working on commercializing the technology.