The Moon is a dusty place, so to tidy things up a bit, ESA is experimenting with high-energy lasers and simulated lunar soil to explore the possibility of sintering lunar regolith to pave roads and landing fields for future lunar outposts and keep the destructive dust at bay.

Even before the first robotic landings, Moon dust has been the bête noire of space engineers. At one time, so little was known about the lunar surface that it was feared that the craters and perhaps whole lunar seas might be filled with very fine dust that would swallow spacecraft like some cosmic quicksand.

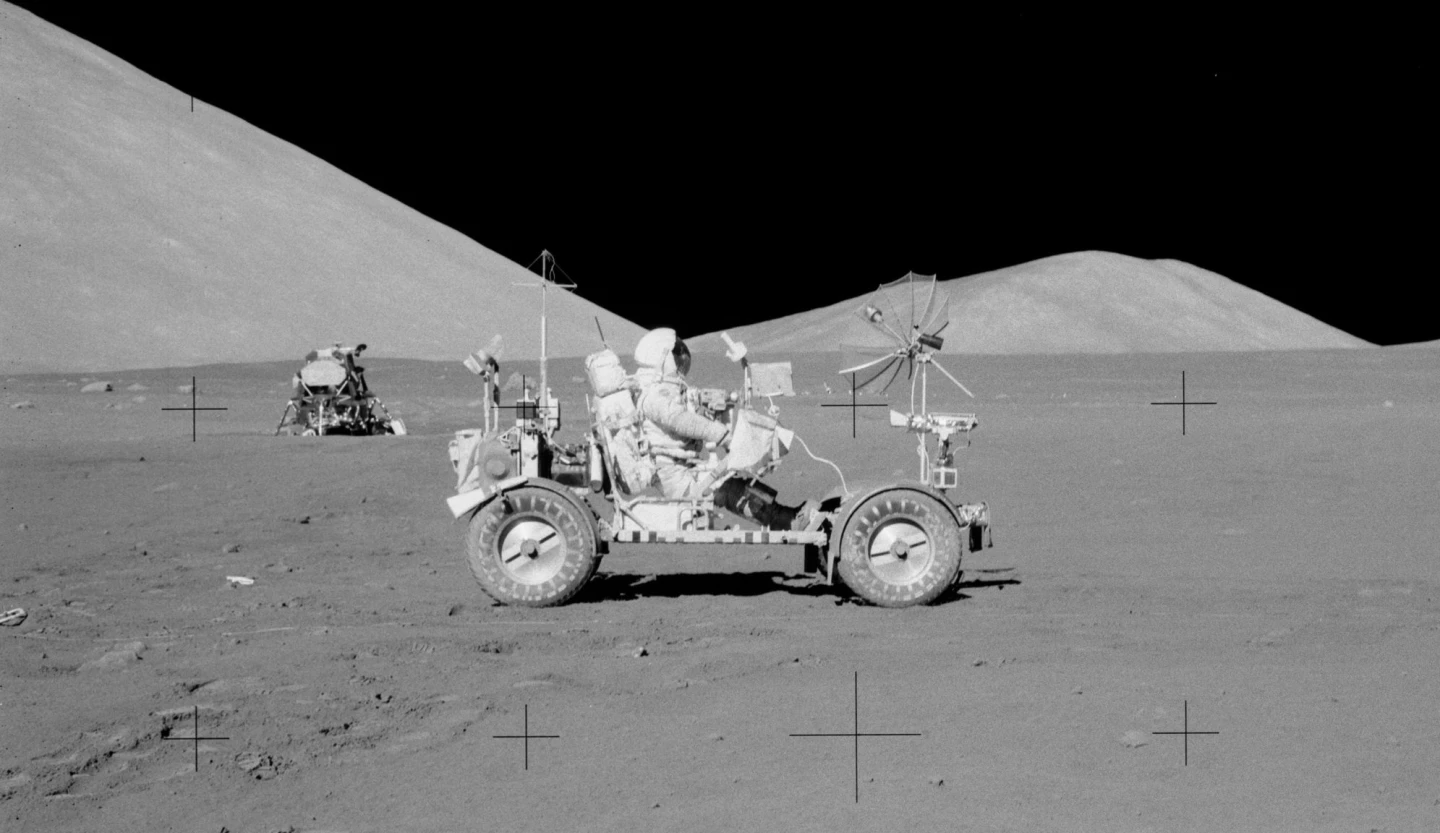

Fortunately, that turned out not to be the case, but what the first explorers found was almost as bad. The lunar dust encountered by the Apollo astronauts and the robotic probes like Surveyor and the Soviet Lunokhod was extremely clingy due to the complete absence of water and an abundance of static electricity, so it coated everything.

Worse, the dust was made of very sharp and abrasive particles that wore out machinery and spacesuits in short order. It was also a strong thermal insulator that almost overheated the rover used on Apollo 17 and destroyed the Lunokhod 2 rover by coating its radiator.

For these reasons, and a number of others, the cliche scene of a moon base sitting serene on the lunar soil is exactly what engineers would like to avoid. The obvious answer is to do what we do on Earth, which is to pave over the roads and work areas. Since asphalt is hard to come by on the Moon, ESA scientists led by Germany’s BAM Institute of Materials Research and Testing have turned to lasers.

The concept isn't new. In 1933, Will W. Beach suggested concentrating sunlight with giant lenses to melt sand to create roads. The ESA team wants to take a similar approach on the Moon using Fresnel lenses a couple of meters across to focus lunar sunlight. But to keep things simple for their experiments as part of the PAVER project, a 12-kilowatt carbon dioxide laser stands in for the Sun and lens.

Working with simulated lunar dust, the PAVER team is doing more than just turning small spots of dust into molten glass. Instead, the 4.5-cm-diameter (2-in) laser beam was used to produce different geometric shapes with a diameter of about 20 cm (8 in) that can be locked together like tiles to form large surfaces like roads and landing pads.

The material is glassy and brittle and can break under compression, but the tram says it can still be repaired in place and can be made stronger by melting larger areas and layering them. Eventually, it should be possible to build structures like a 100-m² (1,076-ft²) landing pad made of a 2-cm-thick (1-in) dense set of layers that can be constructed in about 115 days.

In addition, the PAVER methods could be used to create general building materials for other structures for lunar outposts.

The research was published in Nature Scientific Reports.

Source: ESA