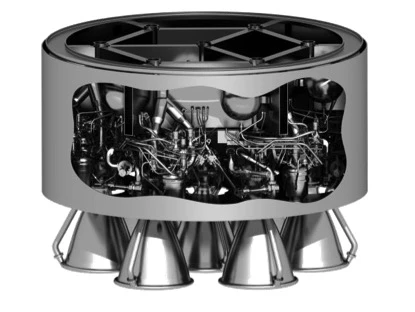

Constructed using 3D printing technology, the Prometheus is a liquid-fueled rocket engine demonstrator that is intended as the model for the next generation of potentially reusable propulsion systems suitable for a wide variety of launch vehicles. Being developed for ESA by ArianeGroup, it promises to be the precursor to rocket engines that are cheaper and more flexible than current designs.

With commercial launch companies coming of age, state-run space agencies are coming under increasing pressure to cut costs to remain competitive. One way to do this is to create new engines that are less expensive to develop and build, can be installed in different rockets in different configurations for different missions, and can be reused.

ESA is betting that Prometheus will lead to new engines that are 10 times cheaper to manufacture than the current main stage Ariane 5 Vulcain 2 engine thanks to a design-to-cost approach to development.

According to the space agency, the Prometheus can be used for both the main and upper stages of launch vehicles, it has variable thrust, can carry out multiple ignitions and needs only minimal ground operations before and after flight. In addition, it runs on a liquid oxygen–methane propellant, which is simpler to handle than some other fuels, and is easier to source.

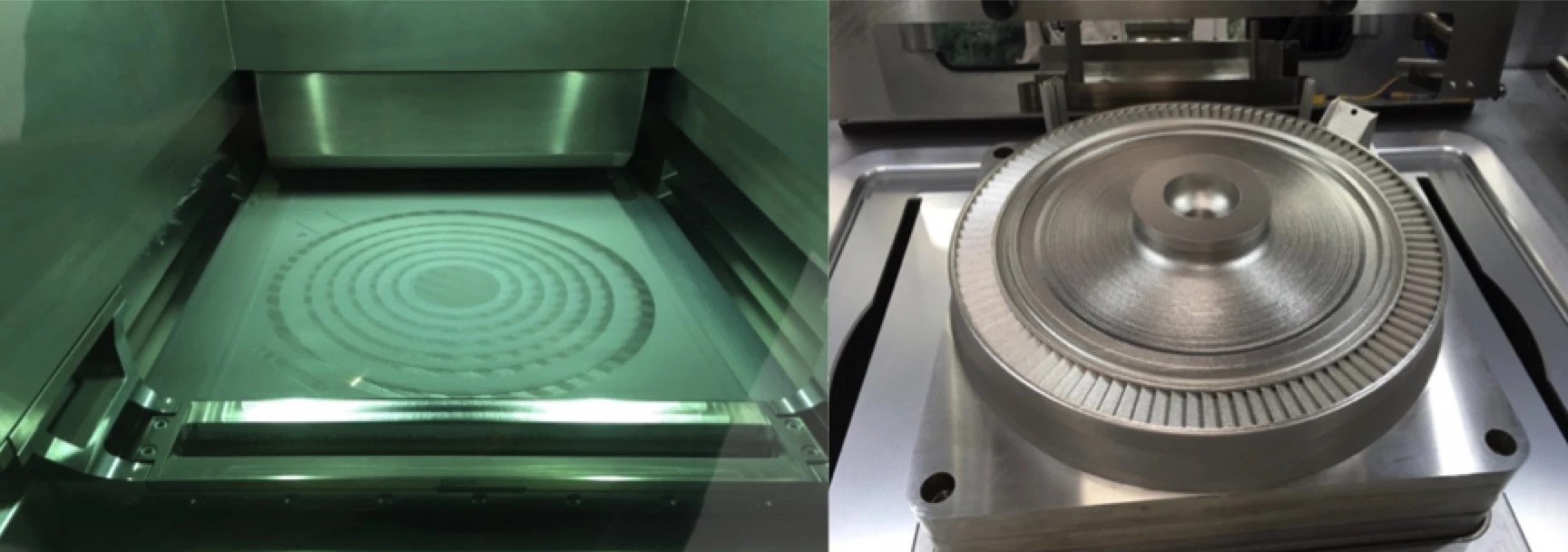

Prometheus's main subsystems are manufactured using 3D printing technology, which allows for faster prototyping and production as well as simpler designs with fewer parts. Printed components include the turbo pump’s turbine, pump inlet, and gas generator valves. For engine management and monitoring there is also an on-board rocket engine computer, which is the component ESA says makes the engine "smart" and potentially resuable.

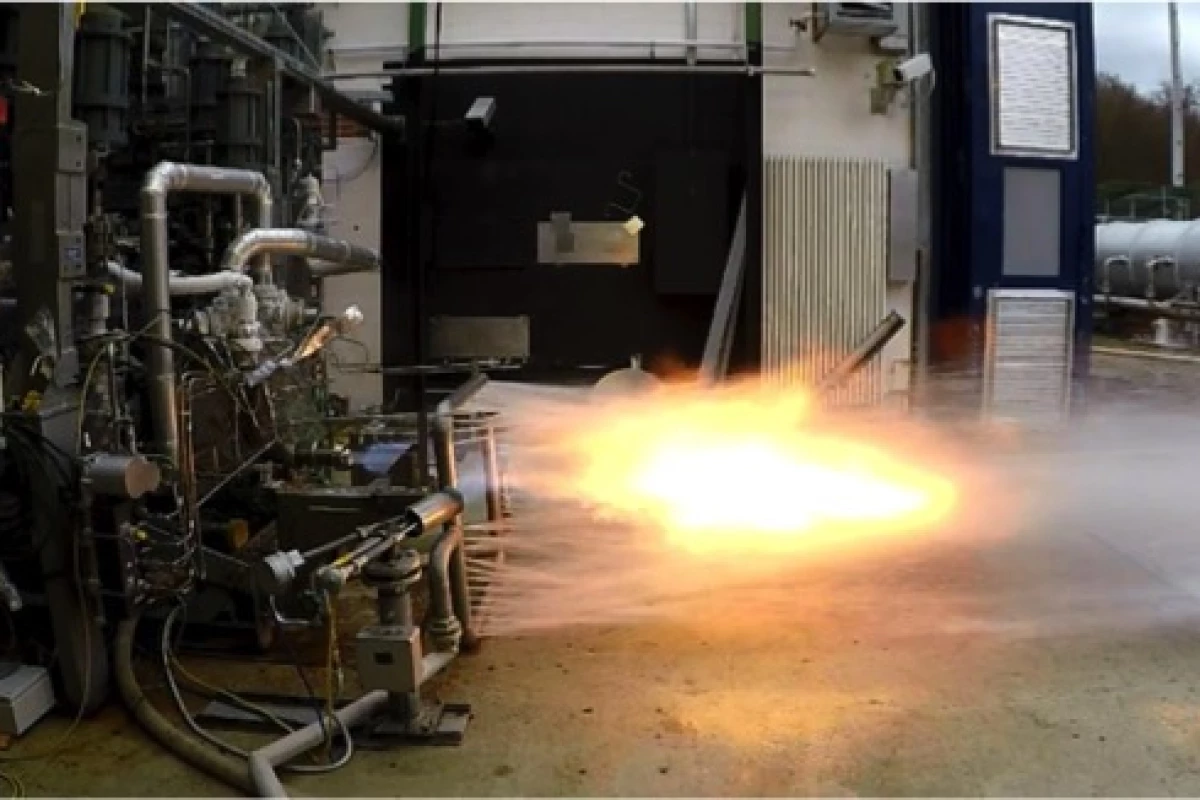

The Prometheus M1 is expected to receive its combustion chamber by December 2020 and the demonstrator will be assembled next year. It's currently undergoing hardware validation tests by ArianeGroup at the DLR German Aerospace Center’s Lampoldshausen testing facility in Germany . ESA says that in the short term, technology developed for Prometheus may be applied to operational engines.

Source: ESA