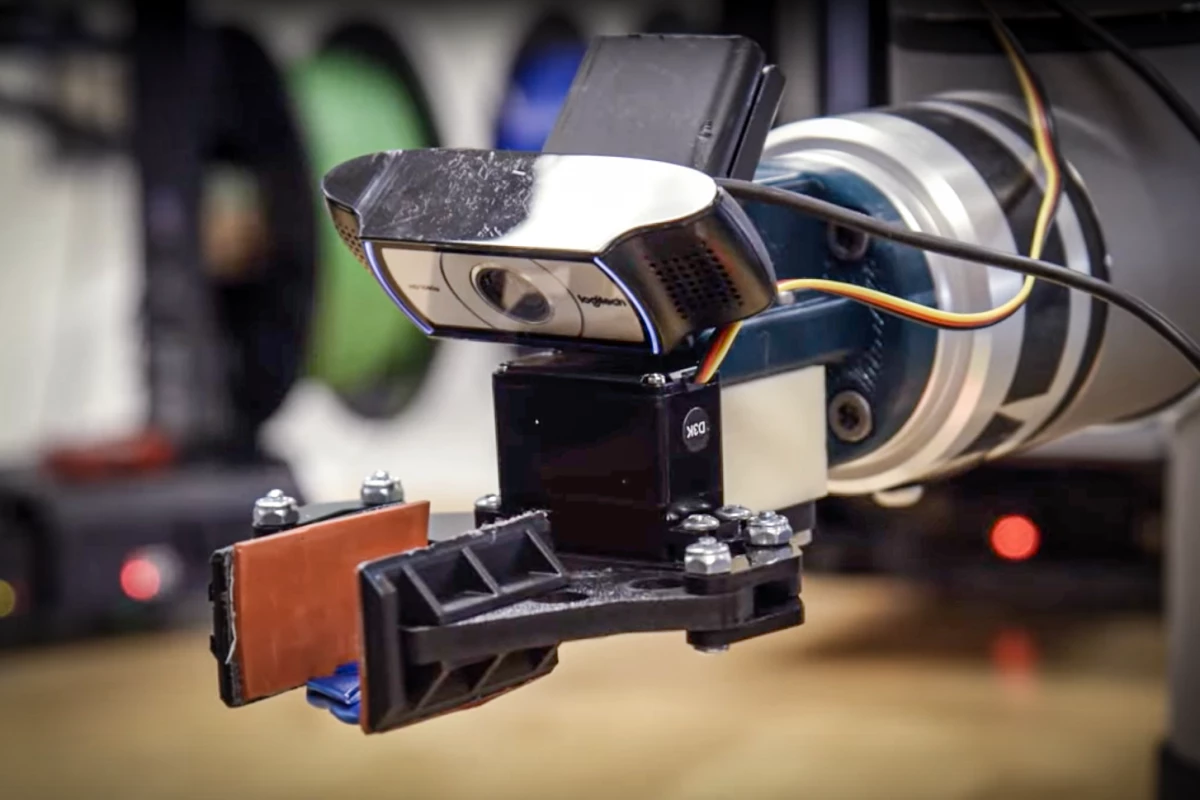

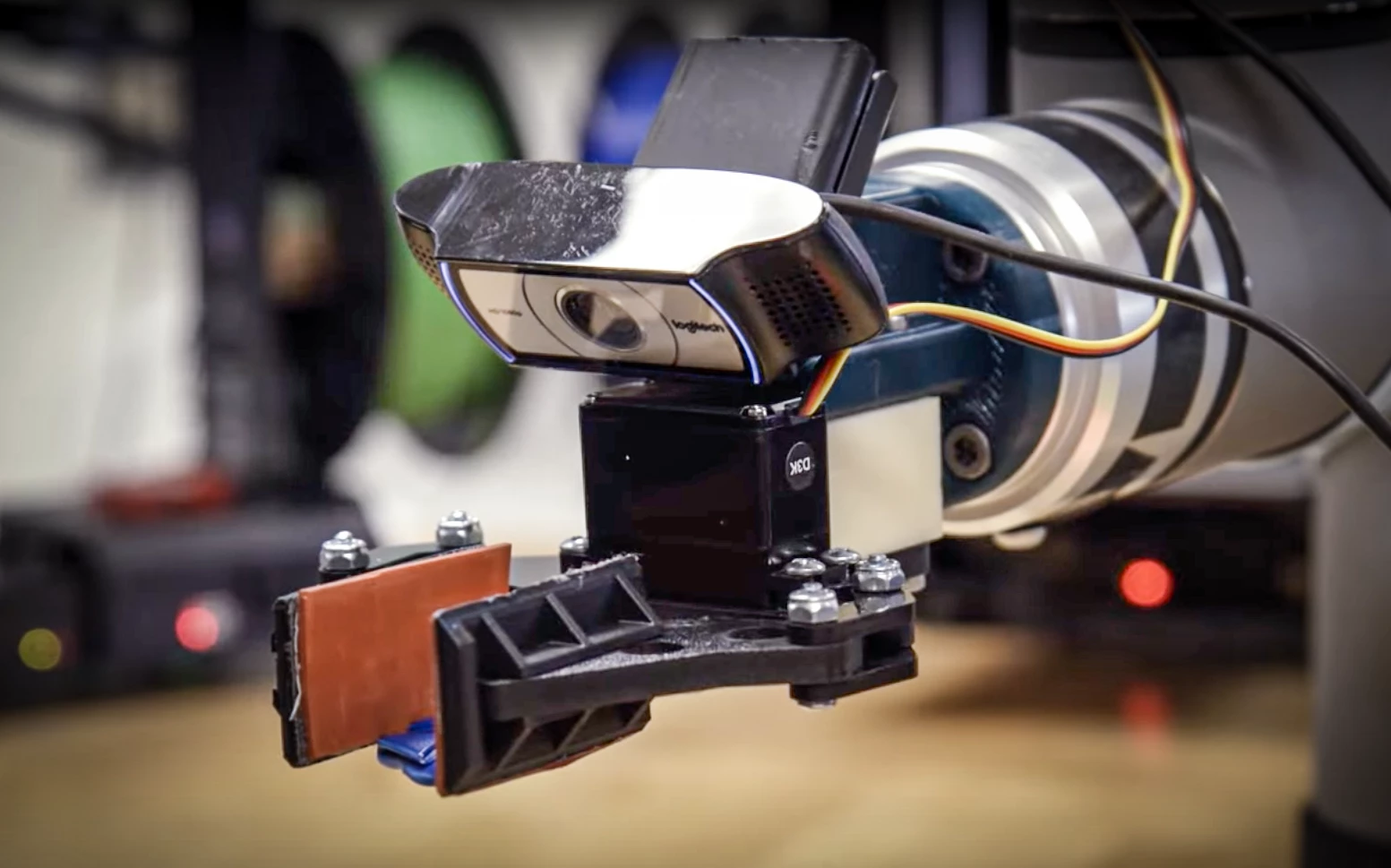

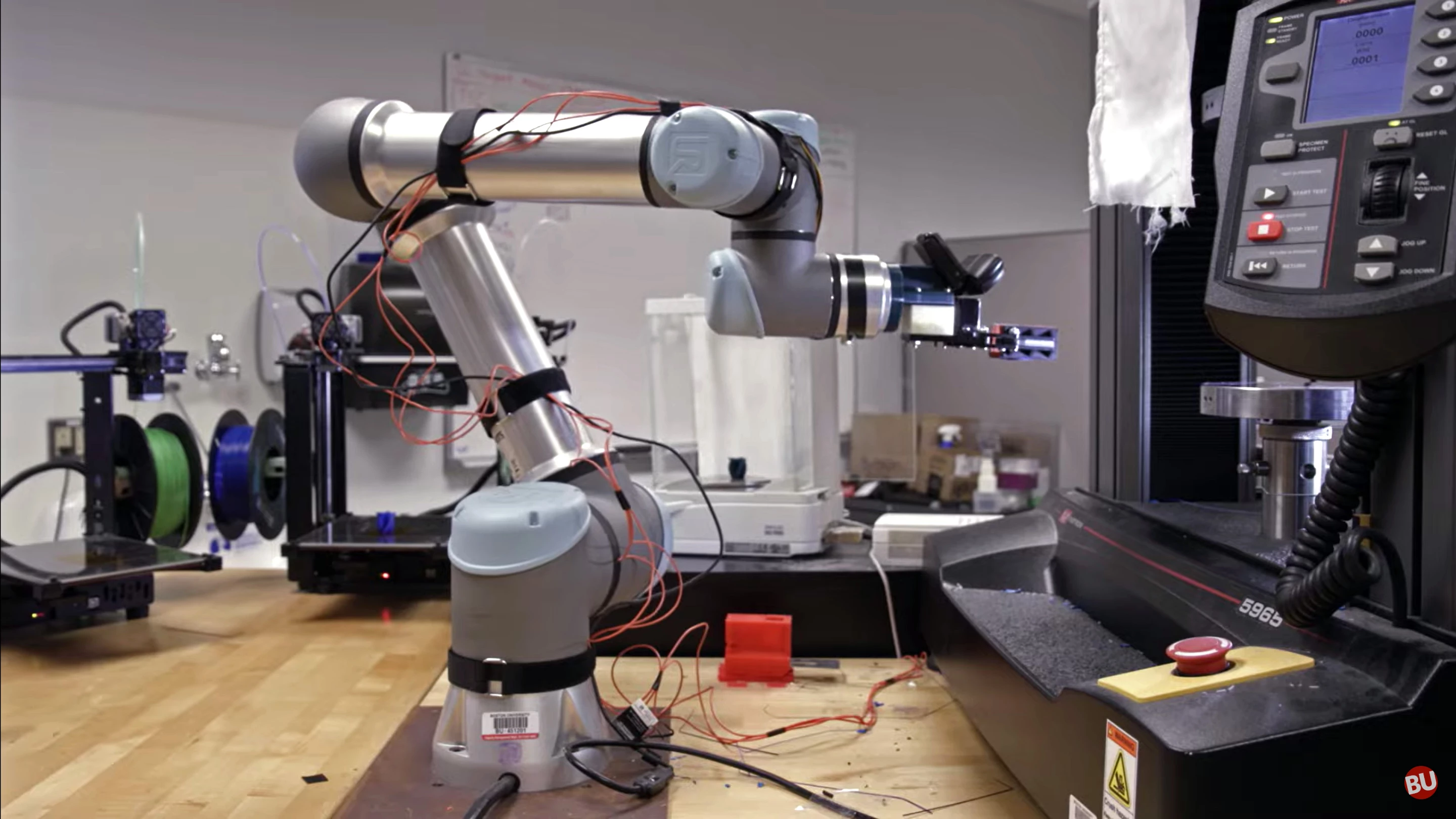

MAMA BEAR – which stands for Mechanics of Additively Manufactured Architectures Bayesian Experimental Autonomous Researcher – 3D prints small structures before gently placing them into a hydraulic press and crushes them. It measures the energy absorption of each little creation it makes as it flattens them into little plastic pancakes. MAMA BEAR then stores the numbers in a database, taking note of each design and its flaws or improvements before slightly modifying the design and diligently 3D printing another iteration – for the last three years straight. Over 25,000 times so far.

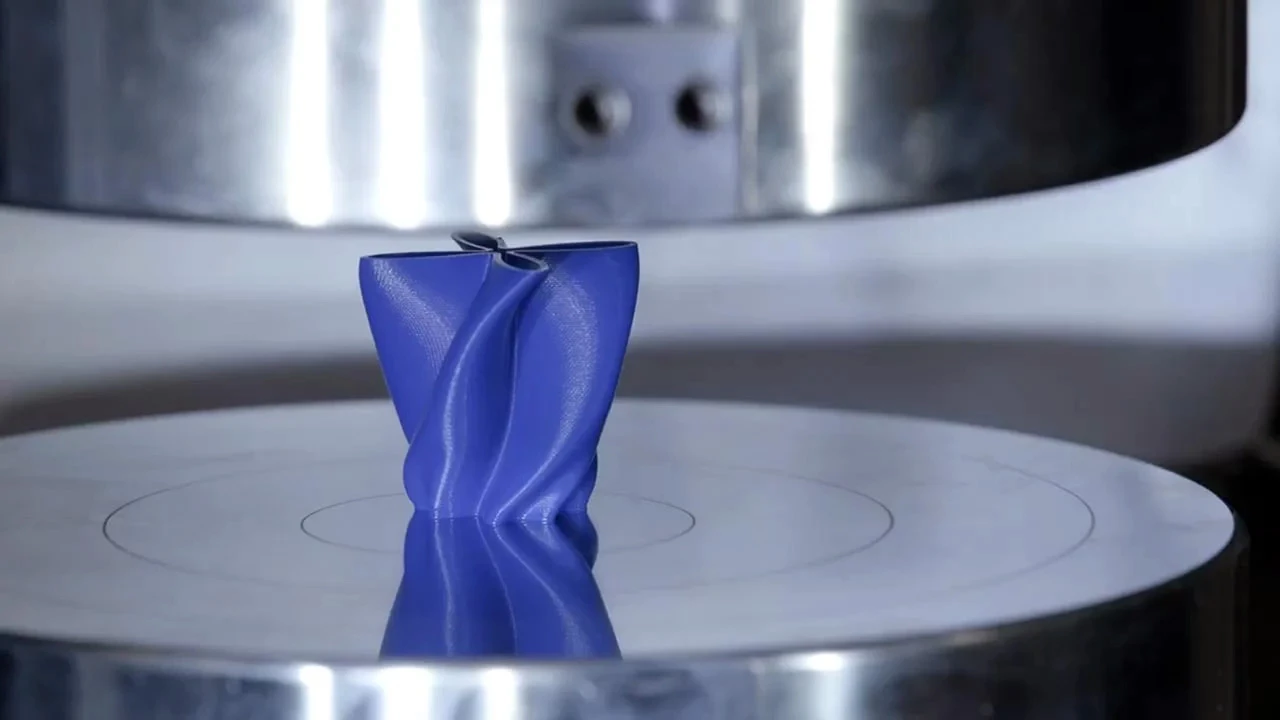

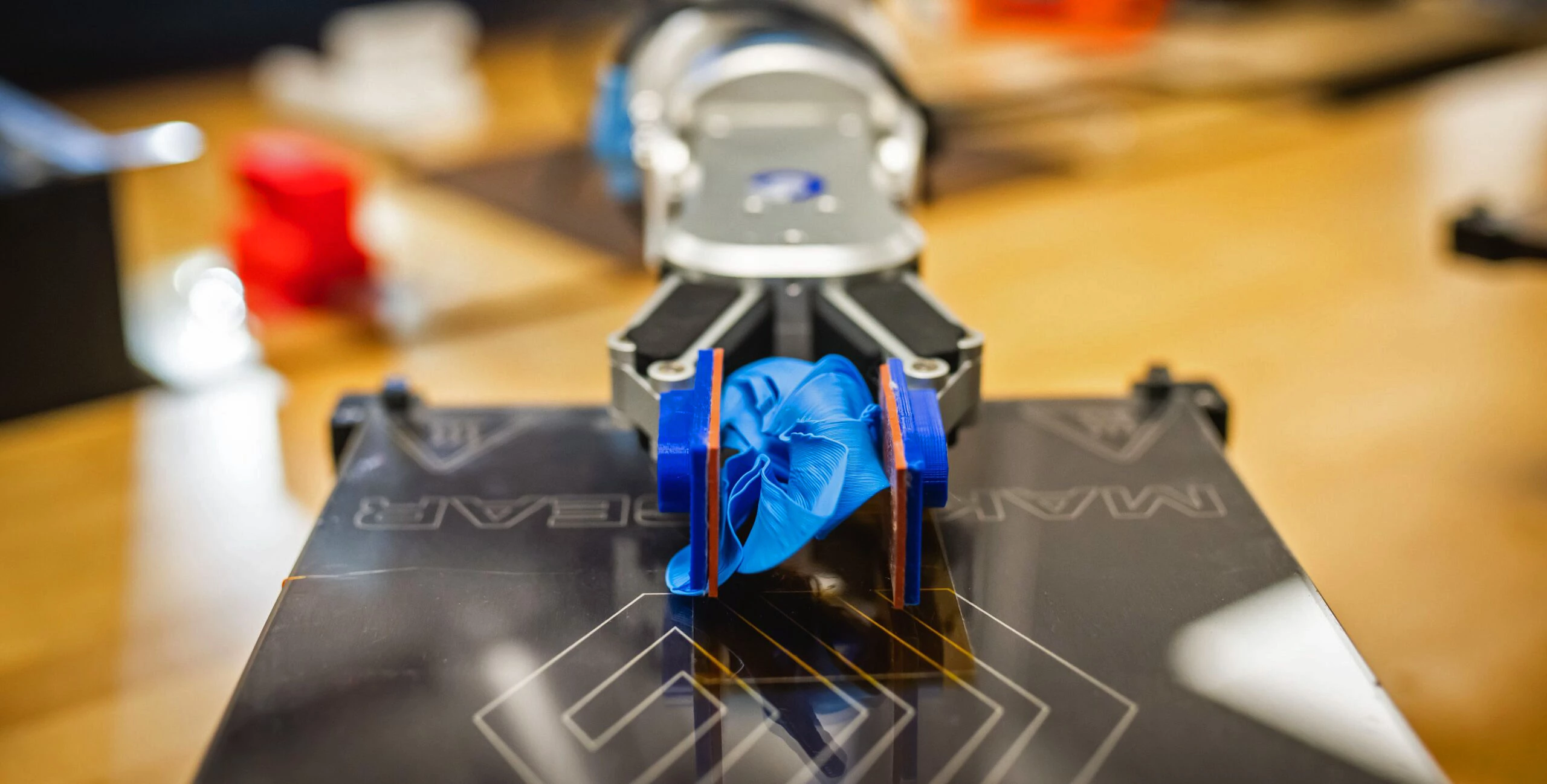

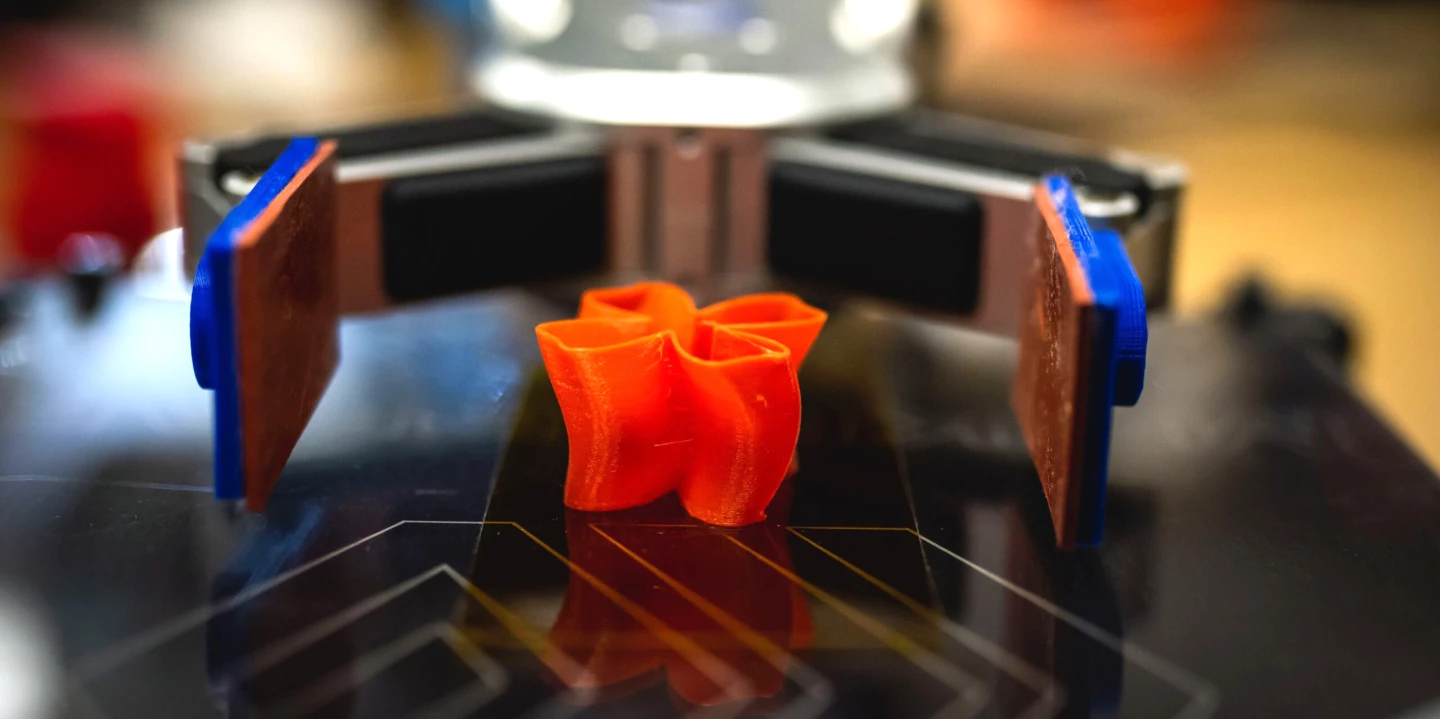

In doing so, MAMA BEAR has set a new efficiency world record of 75% energy absorption, shattering the previous record of 71%. The record-breaking design looks very much like nothing I could have imagined on my own; it's a sort of twisted flower-looking shape.

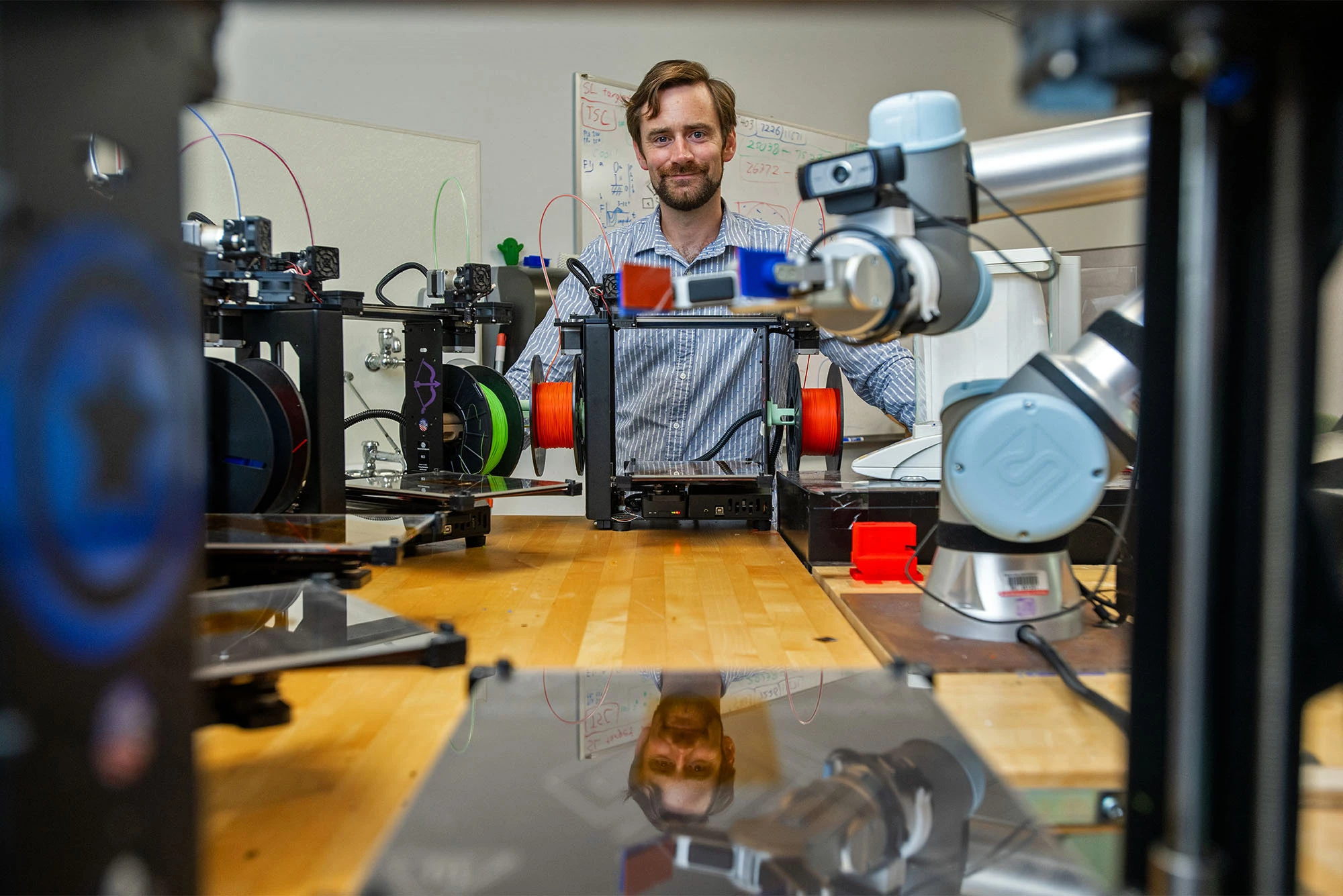

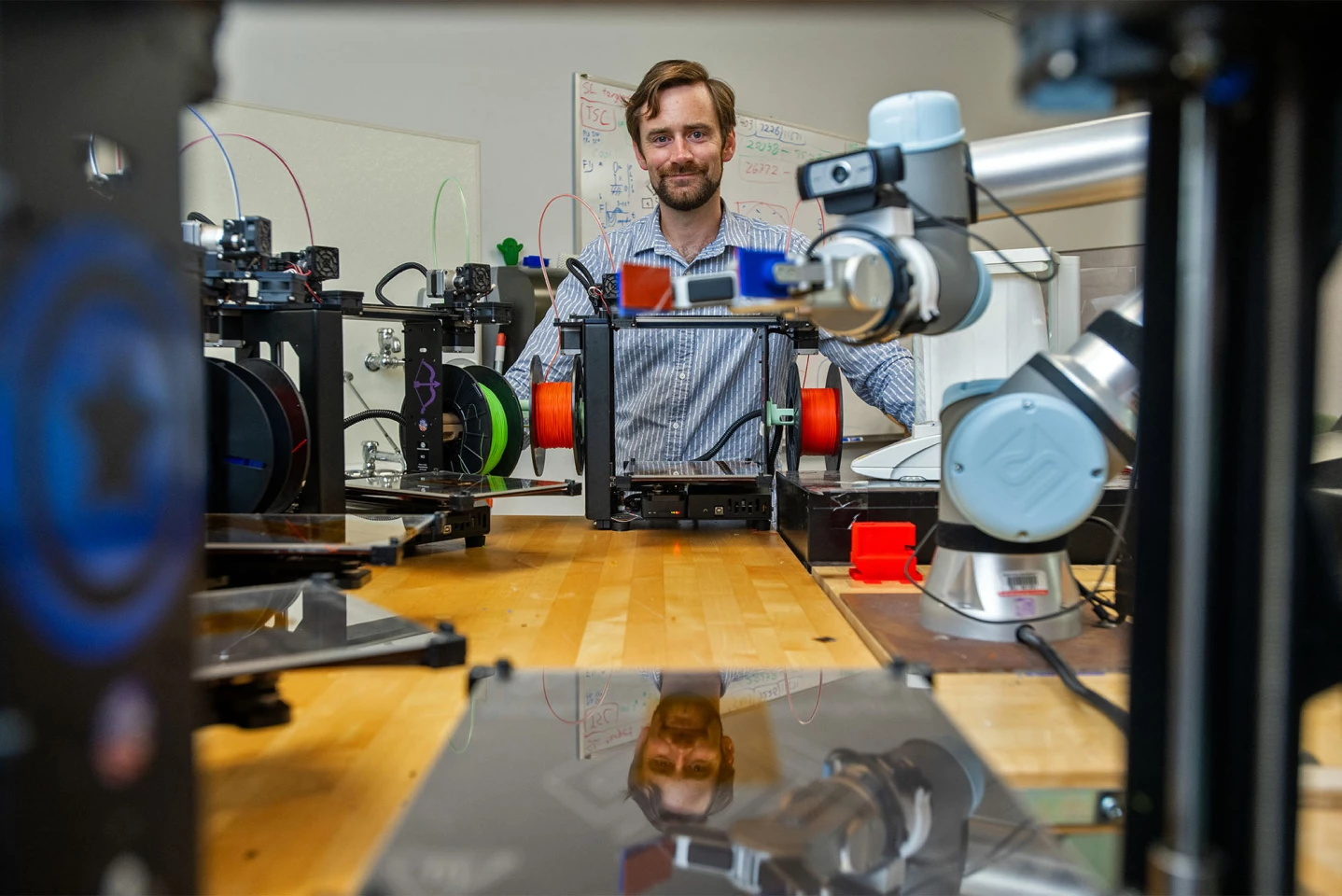

The robot is the brainchild of Keith Brown, an ENG associate professor of mechanical engineering, and his team in the KABlab. He came up with the idea in 2018 and by 2021, the lab was built and MAMA BEAR was off to find a design that was just right.

According to Boston University's article, the robot crushes its creations "under a pressure equivalent to an adult Arabian horse standing on a quarter." I wasn't exactly sure what that meant – though it does paint a fun mental picture – so I took the liberty of converting it to hard data: The median weight of an adult Arabian horse is roughly 880 lb (400 kg). A US quarter is 0.955 inches (24 mm) around. That comes out to around 1,253 psi (86 bar). Squish. You're welcome.

So what's the point? Boston College is trying to make the most efficient mechanical energy-absorbing structure possible for a ton of different potential applications. The National Science Foundation as well as the US Army have a stake in this project. The Army is taking the data and creating a new helmet padding design for battlefield soldiers. And a 4% increase in energy absorption efficiency could literally mean the difference between life and death in such an application.

Or these could be the new packing peanuts. New bumper designs on vehicles. Protective athletic gear. The list goes on for potential uses. It's a delicate balance of trying to create a shape and structure that isn't so hard as to damage whatever it's trying to protect, but still be strong enough to absorb whatever impact comes its way.

It's estimated that there are over a trillion possible designs in the quest for the most efficient structure – not to mention the materials used – so MAMA BEAR has barely scratched the surface of what could be possible. Boston University has been using TPE, TPU-1, 2 and 3, nylon, PETG, and PLA for its designs so far. We're looking forward to more MAMA BEAR achievements in its ongoing quest for perfection.

The team has published a detailed paper with all the scientific data backing their new record in Nature Communications.

Watch the video. It's quite satisfying:

Source: Boston University