For all the promise they are showing in converting sunlight into electricity at ever-improving efficiencies, perovskite solar cells still have some flaws that must be addressed for them to enter widespread use. Among them is the issue of toxic lead contained in the cells and the danger of it seeping out when they're damaged, but a newly-developed film likened to Scotch tape could soak up such leaks.

The research was carried out by scientists at Northern Illinois University (NIU) and the National Renewable Energy Laboratory, and is geared toward making perovskite solar cells commercially viable. While their efficiency now rivals traditional silicon solar cells, the fact they contain lead means they carry a risk of toxicity to the environment and human health if the panel is damaged and the element leaks out.

Swapping out the lead for a substitute is one way scientists may be able to solve this problem, with one interesting example from 2018 using titanium instead. However, the solution proposed by the authors of this new study centers on the idea of leaving the lead in place but capturing it before it can enter the soil or food chain if, for example, the panel suffers damage.

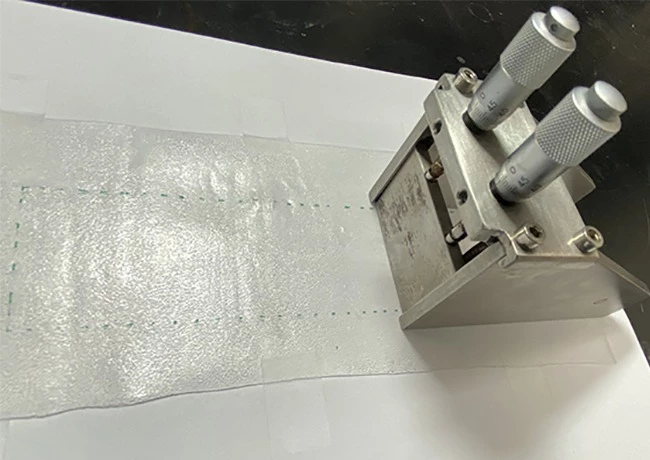

The transparent tape consists of a solar ethylene vinyl acetate (EVA) film and pre-laminated layer of lead-absorbing material, and can be applied to both sides of perovskite solar cells to encapsulate them as part of a standard fabrication process.

Testing the performance of the film involved subjecting the wrapped cells to outdoor, rooftop conditions for three months, damaging them with razor blades and hammers and then submerging them in water for a week. These tests were designed to see how the cells could stand up to severe weather conditions, with the scientists reporting the film to be capable of capturing 99.9 percent of the leaked lead.

“Our practical approach mitigates the potential lead-leakage to a level safer than the standard for drinking water,” says NIU Chemistry Professor Tao Xu, who co-led the research. “We can easily apply our lead-absorbing materials to off-the-shelf films currently used to encapsulate silicon-based solar cells at the end of their production, so existing fabrication processes for PSCs would not be disrupted. At the end of perovskite solar cell production, the films would be laminated to the solar cell.”

The research was published in the journal Nature Sustainability.

Source: North Illinois University via EurekAlert