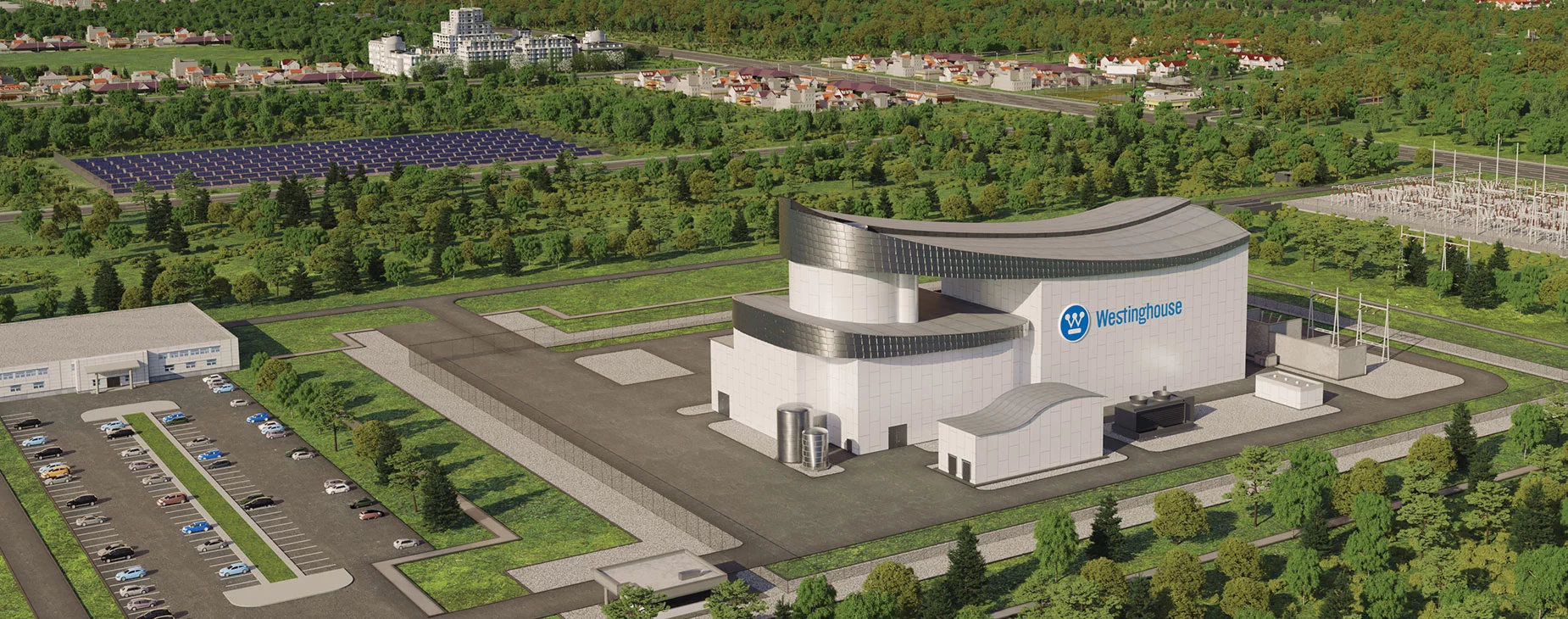

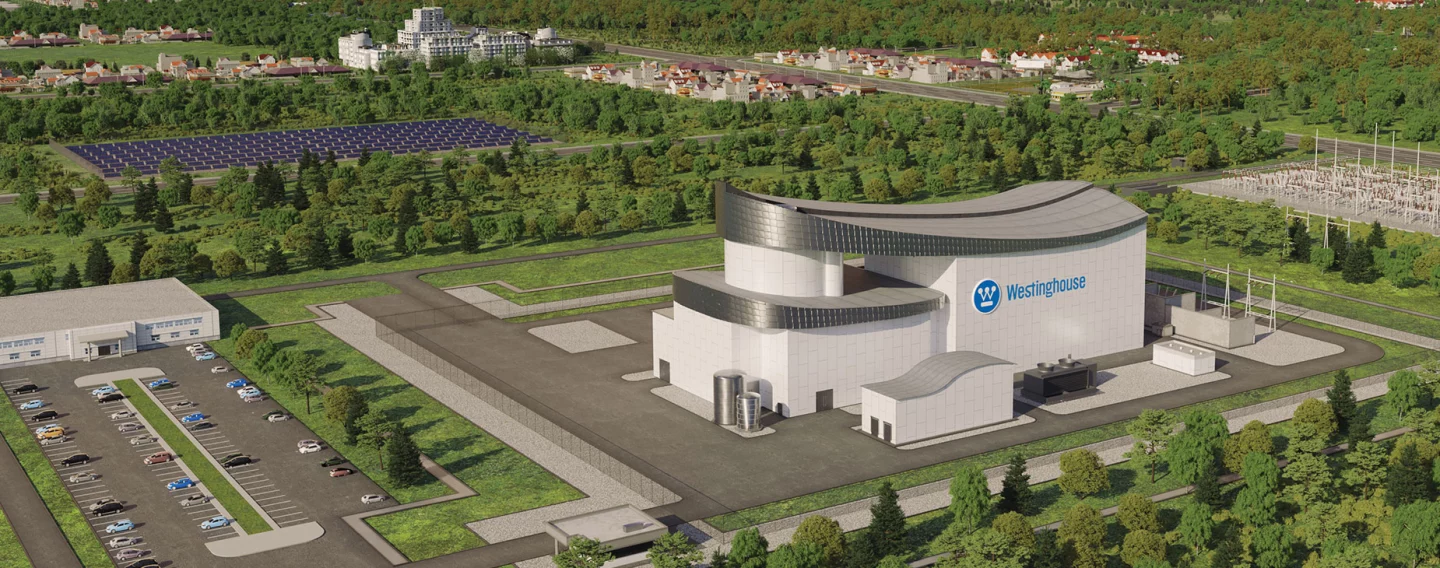

They say that 'small is beautiful,' and the Westinghouse Electric Company seems to have embraced this with the unveiling of its AP300 Small Nuclear Reactor (SMR), which combines Gen III+ reactor technology with a smaller, more economical size.

Small nuclear reactors have been gaining a lot of attention in recent years as an alternative to the giant conventional fission systems that are very slow and expensive to build, and they also attract a good deal of political opposition, which makes them hard to authorize and operate.

The idea behind an SMR is that instead of building one big reactor to serve an entire region, a number of small reactors can be constructed, which can either scale up a power plant by adding more to one site or by dispersing them to meet local needs.

Such reactors not only introduce an element of flexibility, but also make them cheaper by being able to mass produce them in a factory. Construction costs are lowered by reducing much of the civil engineering conventional reactors require, and the heavy concrete containment vessel can be eliminated by installing the reactor underground.

According to Westinghouse, the AP300 is a 300-MWe single-loop pressurized water reactor with an 80-year plus service life and is based on the company's AP1000 one GWe reactor, making it an 'Nth-of-a-kind' plant. This means that the expensive up-front development costs have already been spent on the previous reactor type.

Using 18 years of experience of operating the AP1000, the AP300 takes advantage of improved supply chain, construction, fueling, and operating procedures. The technology is also already approved in the United States, Britain, and China, and complies with European Utility Requirements (EUR) standards, which will speed up licensing in some areas.

Small enough to fit easily on a soccer pitch, the AP300 has a simplified design that is aimed at making it as safe as possible. There are fewer pipes, valves, motors and other points of potential failure, and in the event of an emergency, the shutdown and cooling systems are passive, relying on gravity, natural circulation, and gas pressure rather than diesel engines and pumps. In addition, there are non-safety systems to monitor the reactor and protect it from hazardous fluctuations and a system to flood the reactor containment with large amounts of water to keep the core from overheating in the event of an accident.

The AP300 is intended for both electricity generating and other applications, such as heating, and servicing oil and gas production and industrial sites. It is also aimed at producing hydrogen for the anticipated hydrogen economy.

"The AP300 is the only small modular reactor offering available that is based on deployed, operating and advanced reactor technology," said Patrick Fragman, President and CEO of Westinghouse. "The launch of the AP300 SMR rounds out the Westinghouse portfolio of reactor technology, allowing us to deliver on the full needs of our customers globally, with a clear line of sight on schedule of delivery, and economics."

Source: Westinghouse