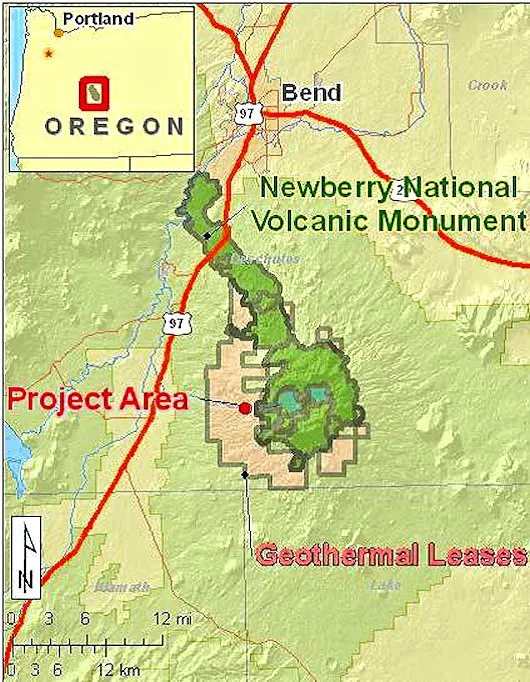

Having successfully negotiated the challenging regulatory slopes of the U.S. Bureau of Land Management, the U.S. Forest Service, the U.S. Department of Energy, and a host of Oregon state agencies, the Newberry Enhanced Geothermal Systems (EGS) demonstration project is in the process of creating a new geothermal reservoir in central Oregon. The core of the new reservoir is a two mile (3.2 km) deep well drilled about four miles (6.3 km) from the center of Newberry Volcano. The rock surrounding the wellbore reaches temperatures in the order of 600° F (315° C), and is nearly impermeable to water. That, however, is about to change.

Newberry Volcano is one of the largest and youngest volcanoes in the United States. Having last erupted about 1,300 years ago, it consists of over 400 individual volcanic vents, which, when combined, form a broad mounded landform referred to as a shield volcano. The Newberry EGS Demonstration geothermal reservoir is being formed in the high-temperature, low-permeability deep lava of the volcano's northwest flank.

The Newberry EGS demonstration is the largest project funded to date by the DOE Geothermal Technologies Program. The DOE has granted over US$20 million to the project, an amount being matched by a partnership between AltaRock Energy and Davenport Newberry.

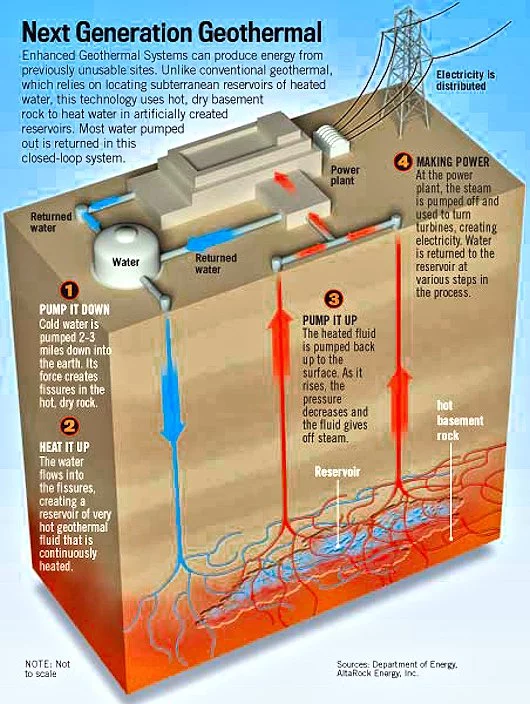

The goal of EGS is to produce electricity by extracting energy from the earth’s heat. To accomplish this, a subsurface system of fractures is formed in hot, impermeable rock, and water pumped down from the surface is circulated through these fractures and returned to the surface as the energy source for a geothermal power plant.

The starting point for creating a new geothermal reservoir is a deep well into hot, dry rock. Well NWG 55-29, drilled by Davenport Newberry in 2008, is well suited as the foundation for a geothermal reservoir. It is 10,060 feet (3066 m) deep into hot rock with very low water permeability.

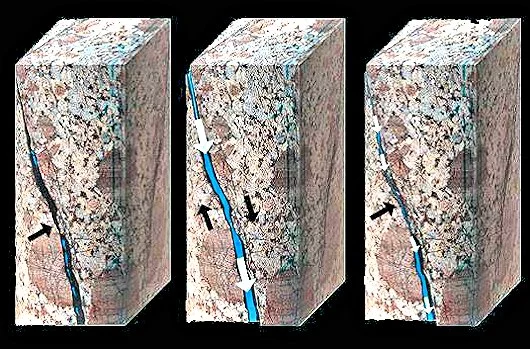

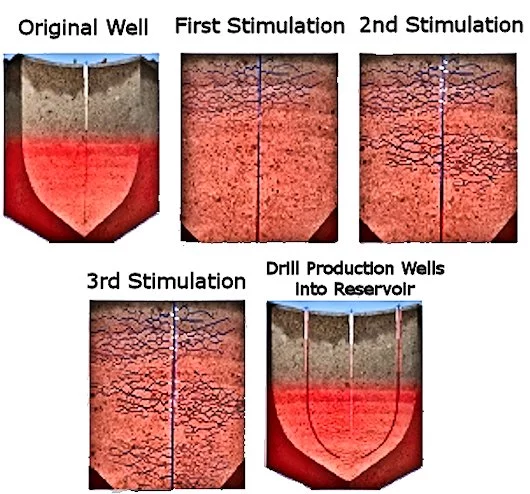

Creating an EGS reservoir requires improving the natural permeability of the hot rock at depth. The process chosen by the Newberry EGS project is called stimulation, in which the natural permeability of deep rock is improved by causing small slips to occur in existing cracks, thereby opening a network of small cracks already present in the rock. This hydroshearing process differs significantly from the hydraulic fracturing used in oil and gas recovery – only enough pressure (about 1600 psi, or 10.9 MPa) is applied to open existing cracks, but not nearly enough (over 5000 psi, or 34 MPa) to form new cracks. In addition, hydroshearing uses only water: the chemical additives used in fracking are not required.

NWG 55-29 has a well casing to a depth of 6,462 feet (1,970 m), after which the well is open to the surrounding rock. This structure is important for the formation of an effective geothermal reservoir. If part of the network of cracks is formed at too shallow a depth, the surrounding rock will be cold, and the production wells will deliver a mix of hot and cold water, resulting in less effective extraction of energy and more complex power plant designs which are able to work at lower temperatures. With the casing, fracture networks will be formed for NWG 55-29 only below the lowest point of the well casing, at a depth where the surrounding rock is very hot indeed.

There is a problem that appears when creating a very deep geothermal reservoir. It takes less pressure to expand cracks at a depth of 7000 feet (2134 m) than it does at 10,000 feet (3,048 m), owing to the additional weight of the covering rock. Accordingly, the more you pump at pressure, the more crack network you open at 7000 feet, but you will never open substantially deeper cracks – the 7000 foot crack network acts as a pressure safety valve protecting the deeper rock.

AltaRock has developed a clever solution for this problem. Thermo-degradable Zonal Isolation Materials (TZIM) represents an important technological advancement in the development of EGS. TZIM is a biodegradable, non-toxic gel-like material. Mixed with the water being injected into well being converted into a geothermal reservoir during the hydroshearing process, the TZIM material seals the newly expanded crack network when the water is removed. A shield is thus formed around the wellbore so deeper fracture networks can be added to the reservoir. After the desired fracture networks are formed, the seals biodegrade to open the crack networks of the new reservoir. Simulation studies suggest that a series of three fracture networks will be suitable for the Newberry EGS project.

On October 18 the pumping equipment was running and a water pressure of 1600 psi (10.9 MPa) was built up inside NWG 55-29. The diagnostics (pumping rate, microseismic detectors, etc.) indicated that hydroshearing and expansion of a network of cracks in the hot rock had begun. However, an unexpected night of freezing weather on October 20 damaged some of the auxiliary equipment, leading to a temporary shutdown of operations. AltaRock hopes to resume testing the stimulation process later this week. The following video gives a very good (if slightly lengthy) description of the project.

Source: AltaRock Energy