While the fabrics we wear today might keep us warm and protect us from the elements, scientists continue to demonstrate how they might soon do far more than that. MIT scientist Yoel Fink has been at the cutting edge of this field for more than a decade and has just made a significant breakthrough, demonstrating the first ever digital fabric-fiber that can store and process information, among other some other exciting functions.

From stretchable fabrics that power wearables with sweat, to shirts that harvest energy from movement, and weavable LED fibers that could form wearable displays, the field of smart textiles is one brimming with exciting possibilities. Fink and his colleagues demonstrated an interesting one way back in 2010, developing fibers that detect sound and can be woven into fabric to turn it into a sensitive microphone.

Fink's team has now broken further ground in this area. They describe the electronic fibers that have been developed so far as analog, in that they can carry a continuous electrical signal but not digital information, which would be processed in 0s and 1s. To bring this kind of capability to textile fibers, the MIT team had to get creative.

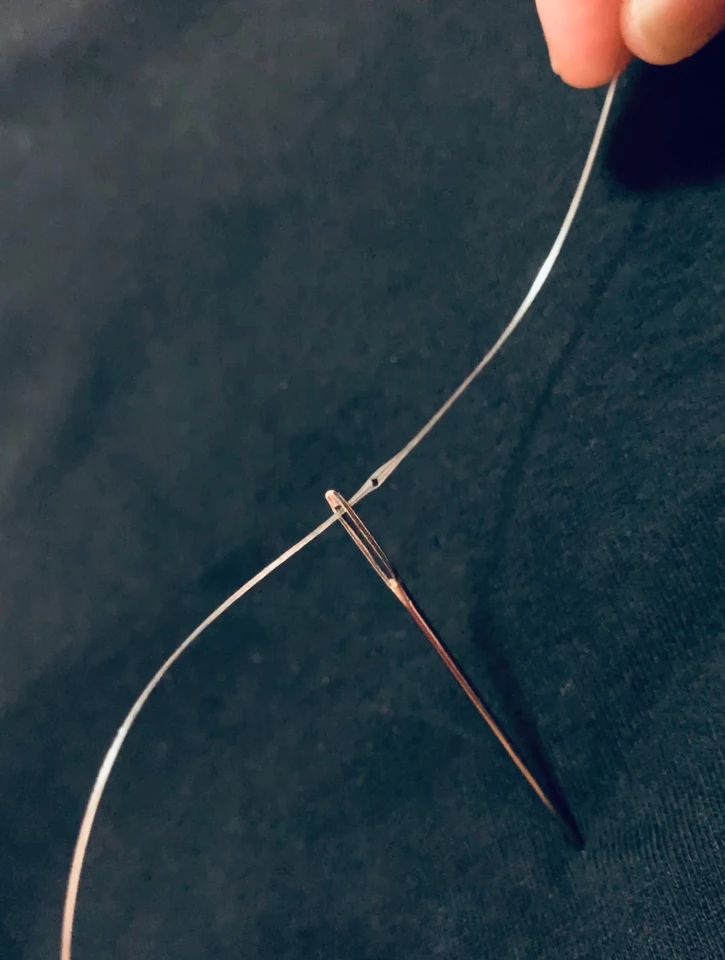

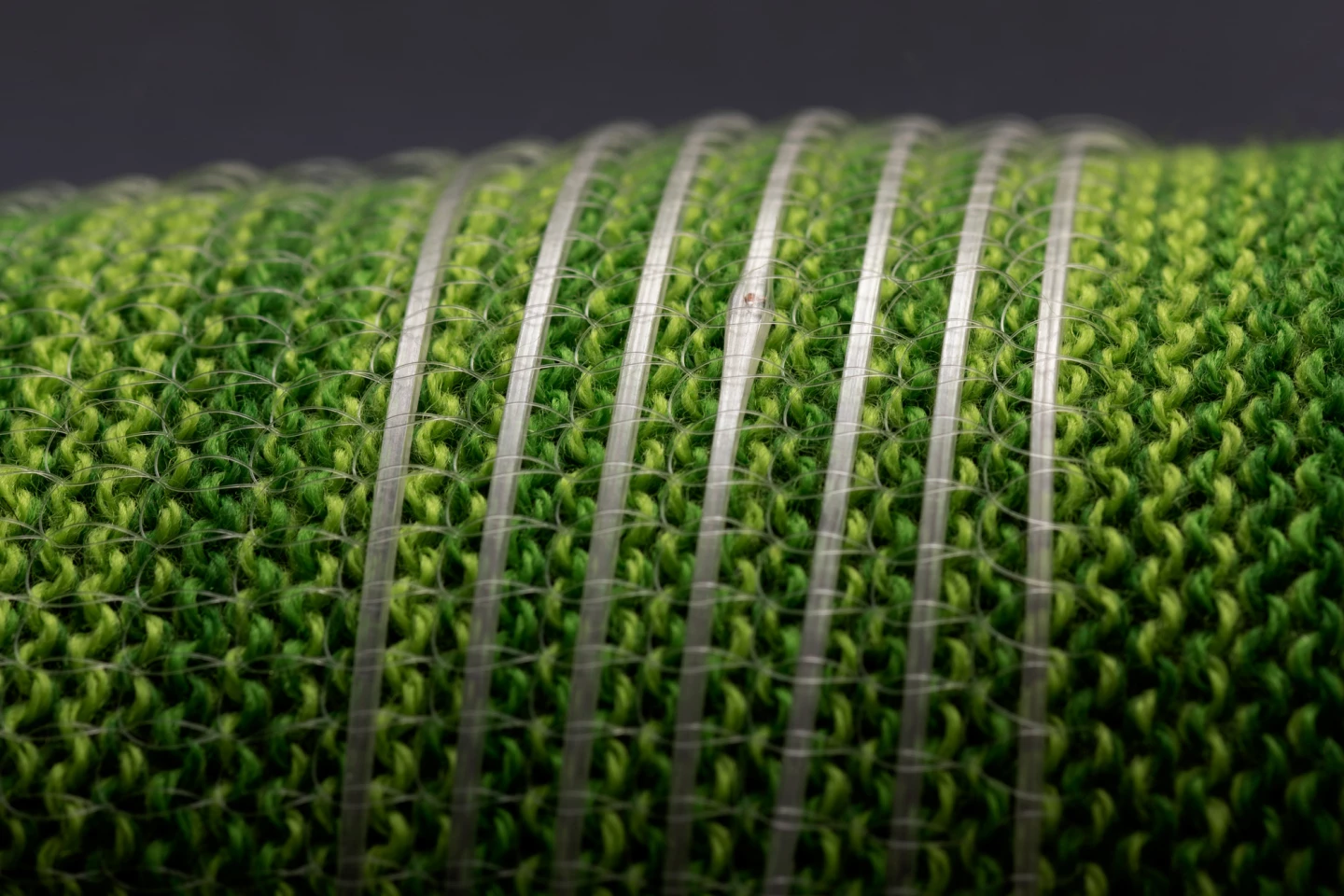

This involved placing hundreds of silicon digital chips into a casting preform, to incorporate it into a polymer fiber. By carefully controlling this process, the team was able to create a fiber measuring tens of meters long, with hundreds of interspersed digital chips throughout and a continuous electrical connection. The fiber is thin enough to be passed through the eye of a regular needle and can be discreetly sewn into fabrics. It even survives at least 10 washing cycles without breaking down.

“When you put it into a shirt, you can’t feel it at all," says study author Gabriel Loke. “You wouldn’t know it was there."

The scientists demonstrated the functionality of their digital fiber by writing, storing and reading information on it, including a 767-kilobit full-color short movie file and a 0.48-megabyte music file, both of which could be stored for two months without power. They also incorporated a neural network made up of 1,650 connections that brings artificial intelligence into the mix.

The researchers put this version to work by sewing it into the armpit of a shirt, where the digital fiber collected 270 minutes of body temperature data on the wearer. The system could even understand the relationship between the sweat data and different physical activities undertaken by the user and, with some training, was able to determine which activity they were engaging in with 96 percent accuracy.

Fabrics with this kind of functionality could be used for longer-term health monitoring by collecting data on the body to recognize early signs of disease, such as an irregular heartbeat or respiratory decline. The scientists plan to continue improving the fiber and opening up even more possibilities for its use, with the next steps to involve incorporating a microcontroller to replace the external device currently used to control it.

“This work presents the first realization of a fabric with the ability to store and process data digitally, adding a new information content dimension to textiles and allowing fabrics to be programmed literally,” Fink says.

The research was published in the journal Nature Communications.

Source: MIT