Although ceramics are known for being able to withstand high temperatures, they also have a reputation for being brittle – they typically shatter when deformed. That's not the case, however, with a spongey new material made from ceramic nanofibers. Developed by scientists at Rhode Island's Brown University and Tsinghua University in China, it could find use in applications ranging from high-temperature insulation to water filtration.

Ordinarily, nanofibers are produced via processes such as electrospinning or 3D laser printing. The former doesn't work well with ceramics, though, while the latter is time-consuming and costly. Instead, the scientists used a technique known as solution blow-spinning, which was developed by Tsinghua's Hui Wu.

It involves using air pressure to drive a liquid solvent containing ceramic material through a tiny opening. As the liquid comes out of that opening, it solidifies into fibers. Those fibers are collected on a spinning apparatus, then subjected to heat to burn away the solvent. What's left is a cotton ball-like sponge made up of tangled ceramic nanofibers.

Those sponges are able to rebound back to their original volume after being compressed by up to 50 percent – no other standard ceramic material can do so. They owe that attribute to the small size of their fibers.

"At the nanoscale, cracks and flaws become so small that it takes much more energy to activate them and cause them to propagate," says Brown's Prof. Huajian Gao. "Nanoscale fibers also promote deformation mechanisms such as what is known as creep, where atoms can diffuse along grain boundaries, enabling the material to deform without breaking."

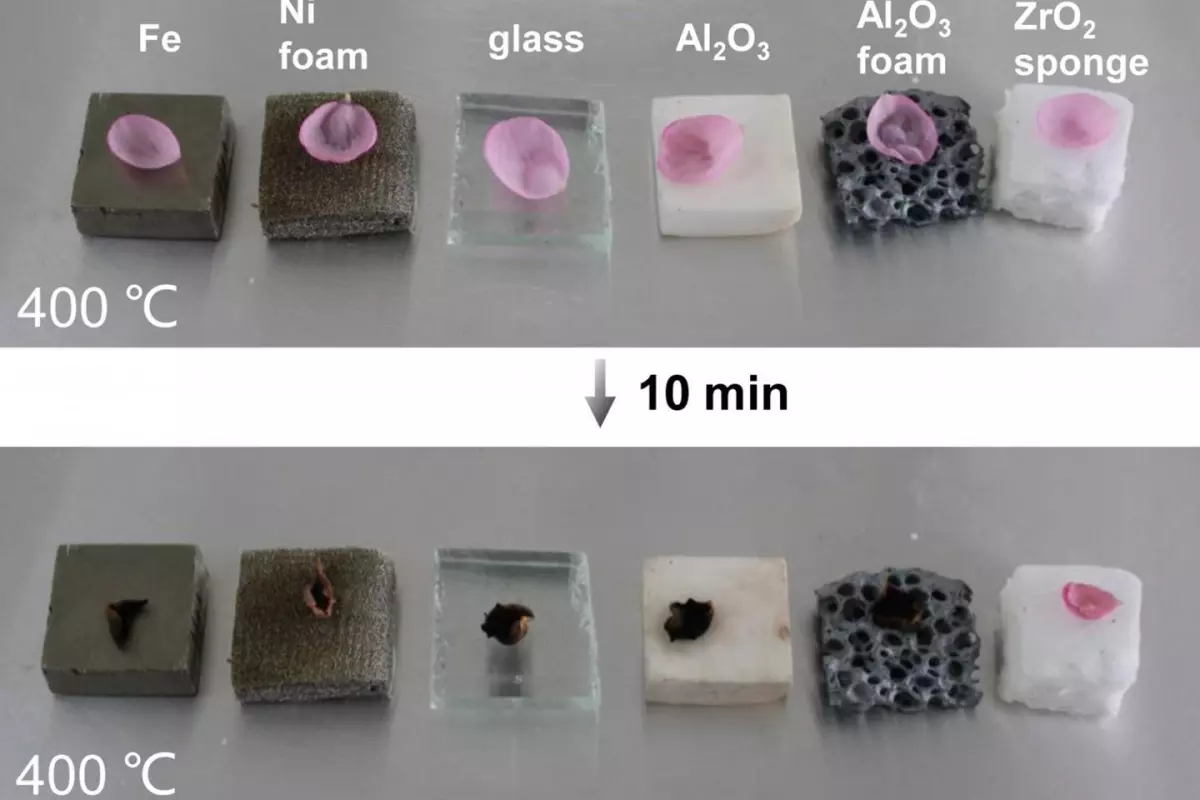

The sponges retain their resilience even when heated to a temperature of 800 ºC (1,472 ºF). In lab tests, a flower petal was placed on a 7mm-thick sponge made of the ceramic zirconium dioxide. Even after the bottom of that sponge was heated to 400 ºC (752 ºF) for 10 minutes, the petal barely wilted. By contrast, petals placed on samples of other porous ceramic materials were burnt to a crisp under the same conditions.

As the ceramic titanium dioxide is a known antibacterial photocatalyst (it kills microbes when exposed to light), sponges made with it could also serve as reusable water filters. Tests showed that a titanium dioxide sponge could absorb 50 times its weight in water that contained an organic dye. The sponge subsequently degraded that dye after 15 minutes of illumination, after which it was wrung out and could be used again.

The researchers additionally believe that the sponges could be used as a heat-resistant flexible insulating material, such as might be utilized in firefighters' clothing.

Source: Brown University