Although an increasing number of devices are being developed for use on or in our bodies, such devices tend not to be very … "body-like." A new 3D printing resin could change that, by allowing for variable stiffness throughout single objects.

With the exception of our bones, our bodies are made up almost entirely of soft biological tissues. Items such as medical implants or wearable electronics, on the other hand, almost always contain at least a few rigid components.

Even when these devices do incorporate some softer synthetic materials, there's always a sharp boundary line where the soft and rigid materials are connected to one another. These boundaries are a potential source of discomfort, reduced functionality, and mechanical failure when placed under stress.

In nature, such abrupt boundaries are typically avoided via biological tissues that gradually transition from low to high stiffness as they stretch from one point to another. Tendons, for instance, smooth the transition from relatively soft muscle tissue to rigid bone.

Scientists from Lawrence Livermore National Laboratory (LLNL) and Meta have now replicated that quality in a "one-pot" thiol-ene-epoxy 3D printing resin. As is the case with other photosensitive resins, this one changes from a viscous to solid state when exposed to patterns of light. Objects are built up by projecting these patterns into transparent-sided chambers of the resin.

In this case, however, the intensity of the light determines the stiffness of the solid. Therefore, by strategically varying that intensity throughout the course of one build, it's possible to end up with a single-piece item that gradually transitions from being soft in one area to rigid in another. The toughness of the material likewise increases by up to 10 times throughout the gradient.

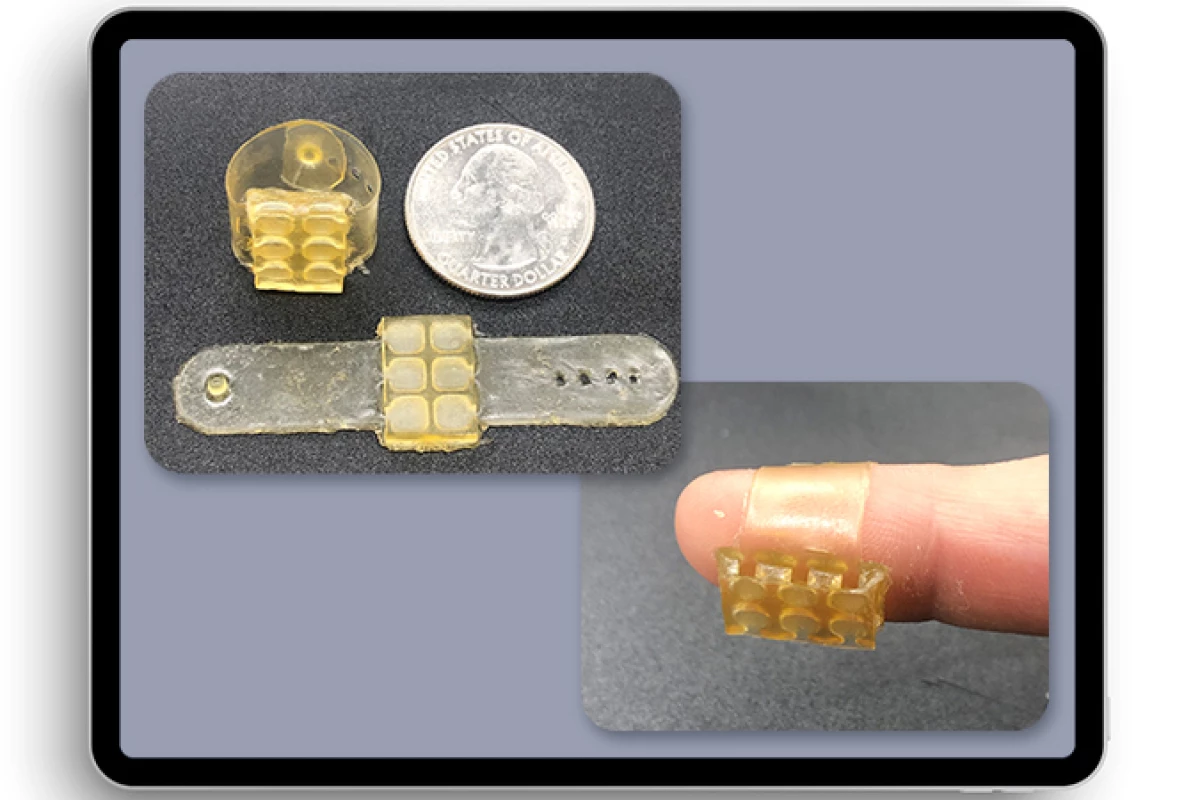

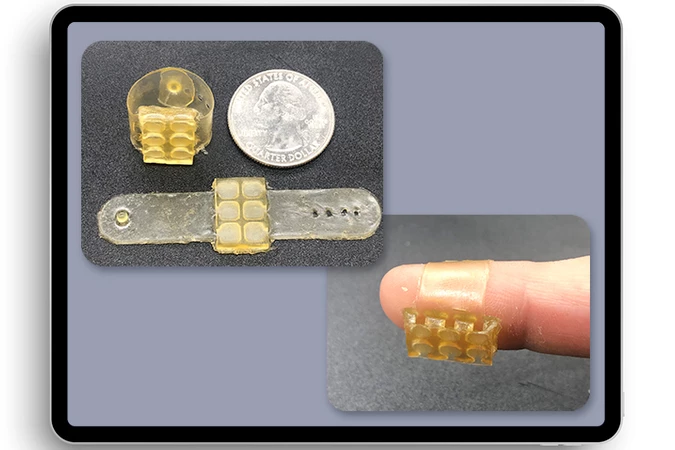

In a demonstration of the technology, the scientists used it to print a one-piece finger-worn device that converts text messages into braille. When connected to an air pump, the wearable pushes air in and out of pads that press on the user's fingertip, replicating the sensation of touching raised braille characters.

"This work has been looking into whether we can design continuous mechanical gradients from soft to stiff in a single resin system," said the lead scientist, LLNL's Dr. Sijia Huang. "Here, we're printing everything we're seeing, just using the light dosage to control the modulus."

A paper on the study was recently published in the journal Matter. For an example of another substance with similar qualities, check out the squid-inspired material that was developed by a team at Case Western Reserve University.