Zero-emissions airliners are still a long way off, but Lufthansa and BASF have developed a way to improve things right now. AeroShark is an adhesive riblet film that immediately reduces fuel consumption, and therefore emissions, from any aircraft.

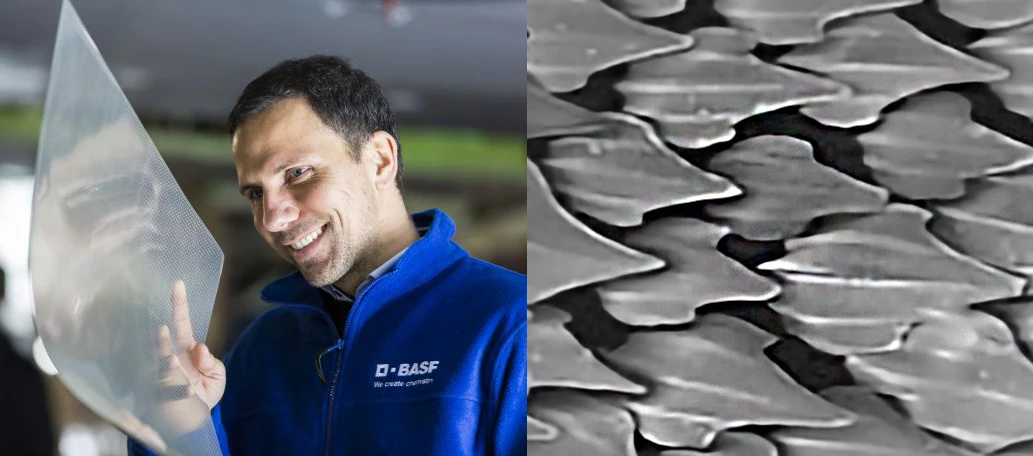

Millions of years of evolution moved the ocean's most feared predators away from perfectly smooth skin. Instead, sharks have very slightly ribbed skin, which reduces drag enough to become an advantage. What works in hydrodynamics often translates well to aerodynamics, so the AeroShark team moved to emulate the texture on the exterior of large aircraft.

The resulting film doesn't sound like a radical difference; the millions of prism-shaped "riblets" on the AeroShark film's surface are no more than 50 micrometers (1/20th of a millimeter, 2/1000ths of an inch) high. But that's enough to make a difference in fuel consumption; international airline Swiss has calculated that if 950 square meters (10,225 sq ft) of this film is applied to a Boeing 777, in specific patterns and aligned with the airflow around the fuselage and engine nascelle surfaces, the reduced drag immediately reduces fuel consumption by 1.1 percent.

Thus, Swiss is sticking AeroShark on all 12 of its 777s, in a move it says will save a staggering 4,800 tonnes of jet fuel a year, reducing CO2 emissions by some 15,200 tonnes in the process. Lufthansa had previously announced it will roll it out on its entire cargo freight fleet as well – a further 10 Boeing 777s, representing 3,700 tons of jet fuel savings and 11,700 tonnes of CO2 emissions avoided every year. The AeroShark team says it's likely to be slightly more effective on cargo planes that don't have window rows to work around.

The team says it's easy to apply, and extremely resilient to UV radiation, water, oil, and the large temperature and pressure shifts you get on the exterior of long-haul aircraft. It's already been tested with more than 1,500 flight hours, on a Boeing 747-400, a modification that was certified by EASA. Applying it to wing surfaces can also help generate extra lift.

Lufthansa Technic and BASF are working to develop the technology further and roll out applications for other aircraft types, and the team says this sharkskin-inspired film could eventually be improved to reduce fuel burn and emissions by up to 3 percent.

Clearly, this kind of drag reduction tech will have relevance beyond the current era of kerosene-powered flight as well.

Check out a video below.

Source: Swiss / Lufthansa Technik