The MIRA I, from German aerospace startup Polaris Raumflugzeuge, was traveling at approximately 105 mph (169 km/h) during takeoff when a "landing gear steering reaction" plus a side wind caused a "hard landing event," rendering the space plane inoperable and its fiberglass airframe damaged beyond repair.

Its subsystems remained mostly intact – however, rather than attempt to repair the prototype spaceplane, Polaris has opted to decommission the 4.25-meter (13.9-ft) long MIRA I to go ahead with the identically shaped 5 m (16 ft) MIRA II and III design. Basically larger copies of the MIRA I.

This ill-fated test was set to be MIRA I's first chance to fire its AS-1 LOX (Liquid Oxygen)/kerosene linear aerospike rocket engine in actual flight – and indeed, the first time any aerospike engine had been properly flight-tested in an actual aircraft.

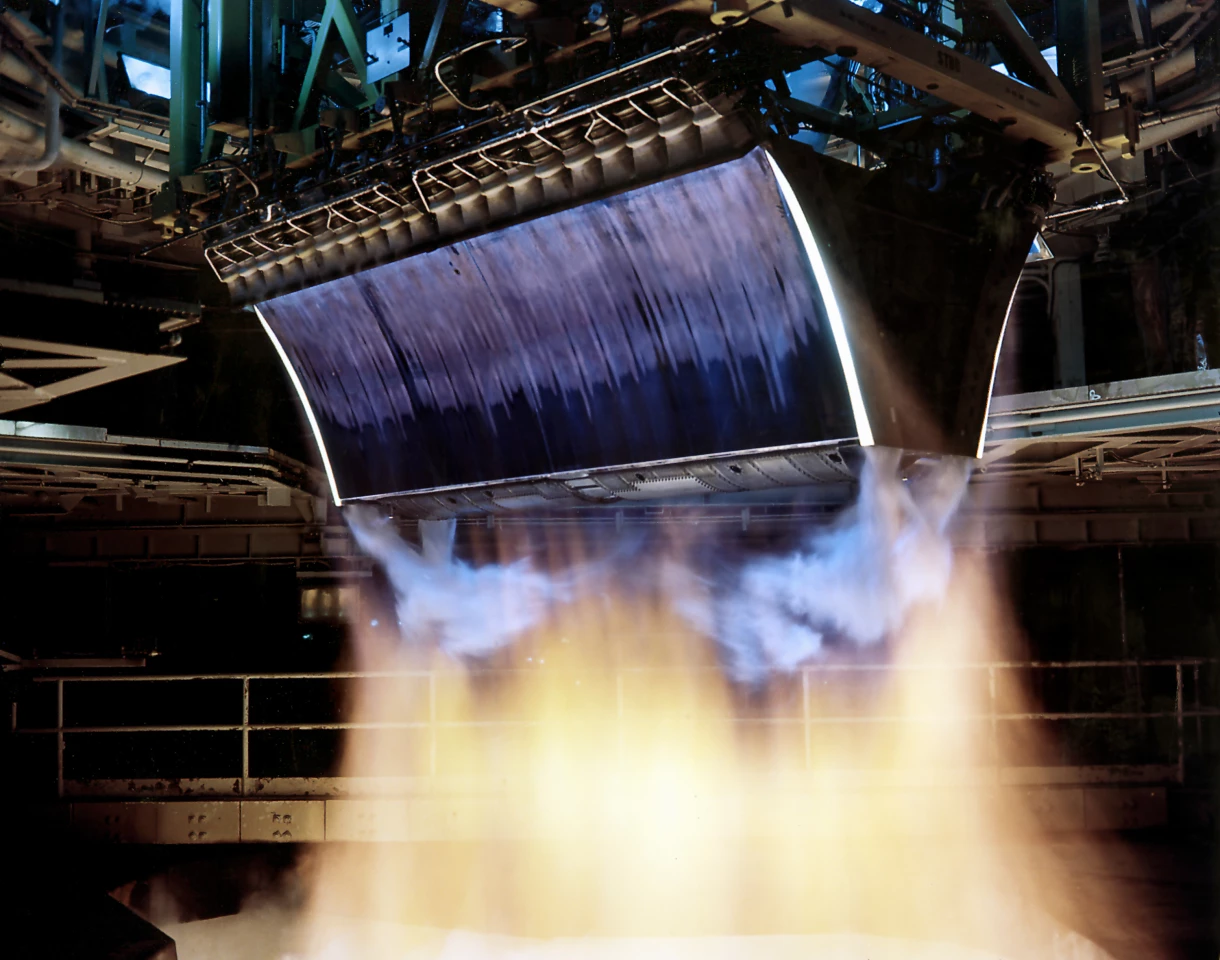

Yes, an aerospike rocket engine, developed in-house by Polaris. If that sounds like something from science fiction, well, it almost is. They were first invented in the 1950s by Rocketdyne, but have never been used outside of a lab.

The easiest way to imagine an aerospike engine is to take a conventional bell-shaped rocket engine nozzle, and more or less turn it inside-out, making the inner cross section half of the bell shape and leaving the outside open to the atmosphere.

Why? Traditional bell-shaped rockets can only operate at peak efficiency at a specific altitude, defined by the shape and size of the bell. As the rocket goes higher in altitude, the atmospheric pressure decreases and efficiency drops – thus requiring different rocket stages, using different bell shapes and sizes for different phases of a launch.

In lab tests, the aerospike engine design can get around this issue. Effectively, aerospike designs use the ambient atmospheric pressure around the rocket as the external wall of their nozzles. The changing pressure at different altitudes combines with aerodynamic effects to change the size and shape of the envelope of air pressure around the engine, pushing the fiery goodness of the expanding gases back against the cross section of the half-bell to create more pressure, speed up the exhaust and focus the thrust.

So while a conventional rocket will be more efficient within its operational limits, aerospike designs maintain a strong average efficiency from sea level all the way up to the vacuum of space, self-compensating as pressure levels change without the need for extra moving parts.

While the MIRA I didn't get a chance to prove this technology in flight, the new MIRA II and III will feature the same propulsion layout: four kerosene jet turbines and the single AS-1 aerospike rocket engine that were equipped on MIRA I. The main difference is the size of the airframes; go big or go home, right?

Another factor that makes the MIRA project different is its delta-wing airframe, designed to be completely reusable for transport to and from orbit. If all goes to plan, it will be able to carry payloads or passengers as a fully-functional, reusable, Single Stage To Orbit (SSTO) spaceplane.

In a press release posted to LinkedIn by Polaris Spaceplanes, the company keeps things positive: "At Polaris, we are advancing our project at an exceptionally rapid pace. To facilitate such swift progress, we fully accept that sometimes things can break... If you don’t break things, you are not ambitious enough."

Source: Polaris