Tasked with building a new data center in an urban area of Germany, the team behind the Wave House harnessed the benefits of 3D printing technology to inject a sense of style into the unglamorous world of cloud-computing infrastructure, creating Europe's largest 3D-printed building in the process.

The Wave House is located in Heidelberg and was designed by SSV and Mense Korte, and created by Peri 3D Construction for developer KrausGruppe. It measures 600 sq m (6,600 sq ft). As mentioned, its unusual appearance comes from an attempt to spice up what could otherwise have been a rather boring building.

"Due to the typical absence of windows and large openings in all or the main areas of data centers, for safety and other reasons, data centers tend to look quite dull and uninspiring," explained a press release by COBOD. "As long as such data centers are placed far outside the cities this problem is perhaps of less concern, but the trend towards making data centers more in the vicinity of the users and therefore locate them in suburban areas and cities has created a need to make the data centers more visually appealing.

"A challenge that in the Heidelberg project was solved by the architects SSV and Mense Korte by giving the walls a wave design, a design feature that also gave name to the building: the Wave House. Such wave designed walls could not have been realized using conventional construction methods, so instead 3D construction printing technology was used due to the design freedom of this construction method."

The build process was similar to other 3D-printed architecture projects we've reported on and made use of a single COBOD BOD2 printer, the same model which was also used in Europe's first two-story house and the world's largest 3D-printed building. The 3D printer extruded a recyclable cement-like mixture out of a nozzle in layers, at a rate of 4 sq m (43 sq ft) per hour to form the exterior walls, which measure a length of 54 m (177 ft), a width of 11 m (36 ft) and a height of 9 m (29.5 ft).

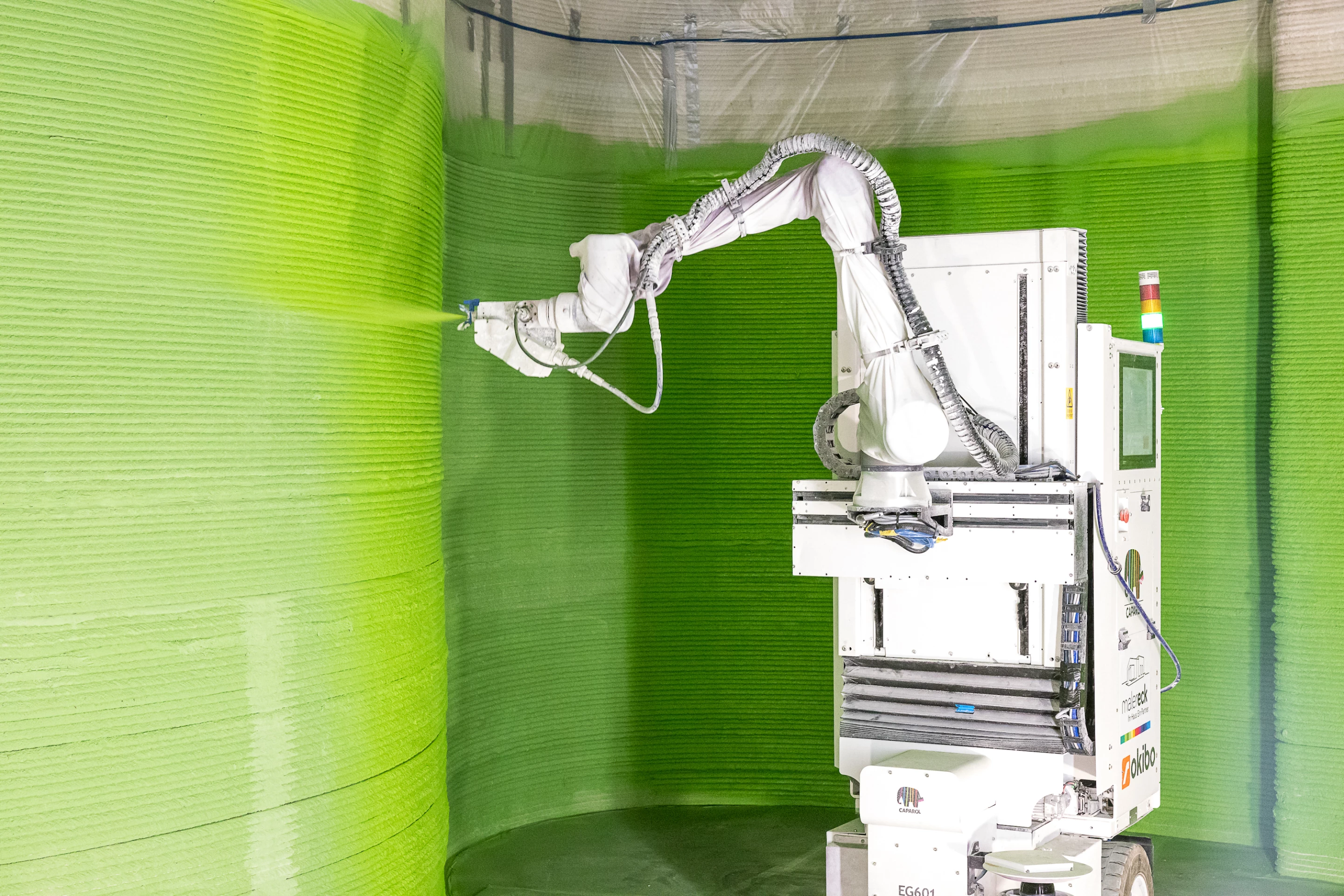

The printing process took around 140 hours. Following this, humans then put the finishing touches to the project, including the roof and doors, plus the lighting and all the wiring and gear required for a modern internet-connected data center. However, a robotic painter by Deutsche Amphibolin-Werke was used to paint the interior.

According to the Kraus Gruppe, the 3D-printed construction process resulted in significantly less CO2 than traditional methods would have. The entire project, including both robot and human labor, took from April to October, 2023.

3D-printed architecture has moved decisively into the mainstream in recent years and the Wave House follows several notable projects including an earthquake-resistant 3D-printed house, the world's tallest 3D-printed tower, and an ambitious development of 100 3D-printed homes. COBOD says it hopes to eventually automate a minimum of 50% of construction processes on building sites, which should be great for company profits, though perhaps not for the job security of some human builders.

Sources: COBOD, KrausGruppe [in German]