While dashboard-integrated trays are useful for storing items such as sunglasses, they can also add to a sense of in-car clutter. With this in mind, German scientists have created a tray that flattens into the dash when not required.

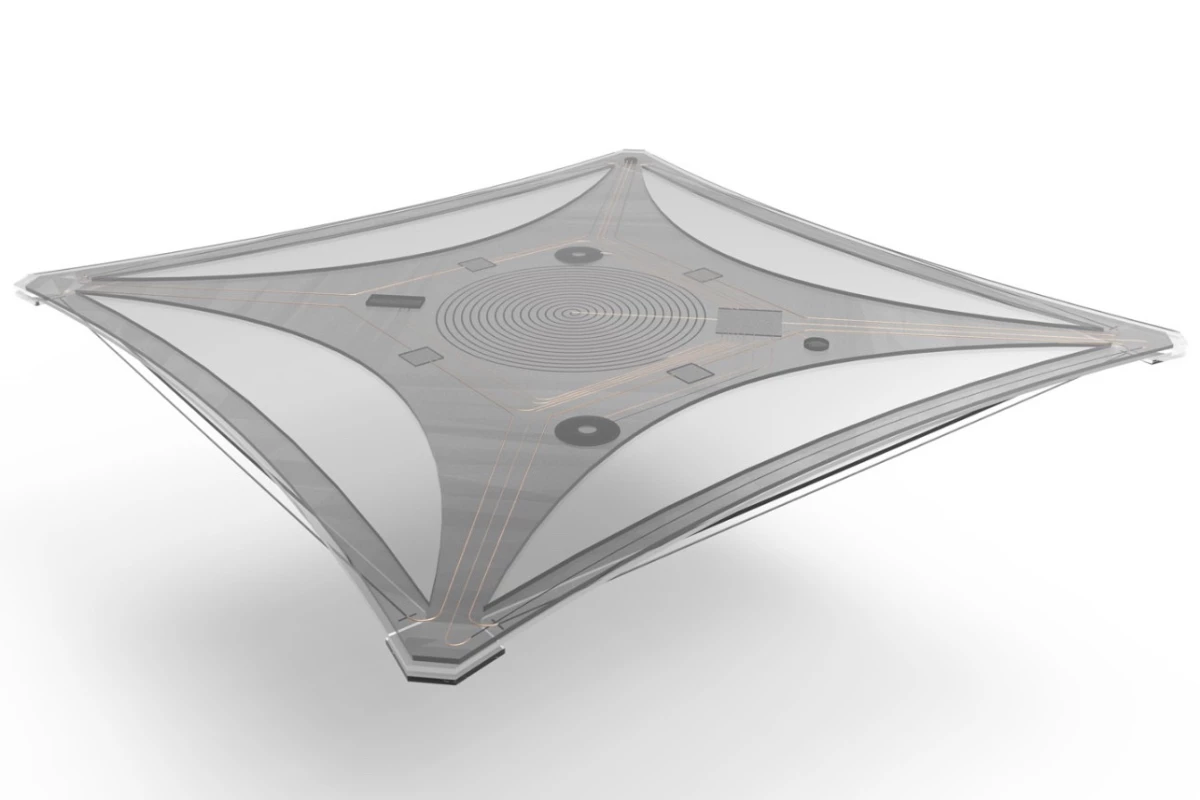

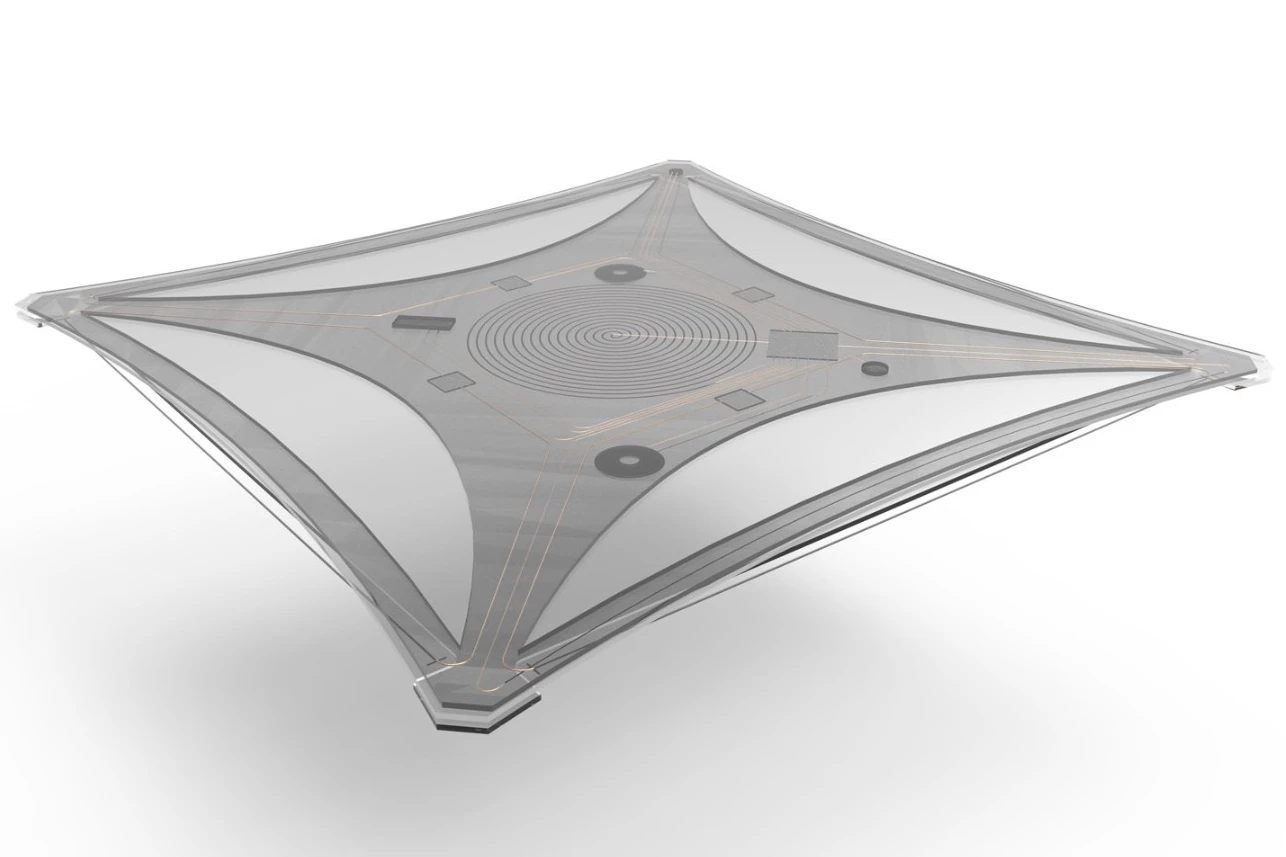

Developed at the Fraunhofer Institute for Machine Tools and Forming Technology, in partnership with auto parts manufacturer Brose Fahrzeugteile, the device ordinarily forms a flat, flexible square-shaped part of the dashboard's smooth surface.

When the driver or passenger requires a cubby hole in which to store something, though, they just wave their hand over that part of the dash. This motion is detected by an integrated sensor, triggering an electrical current to briefly flow through wires that connect the four corners of the square.

Those wires are made of a shape-memory alloy, which automatically contracts into its original shape when heated. Therefore, as the current quickly heats the wires, they contract, pulling the corners of the square inward and pushing its center downward in the process.

As a result, a depression forms in the dashboard. It remains in place until the shape-memory wires are electronically triggered to flatten back out again – this can happen manually via a subsequent hand gesture, or automatically as a sensor detects that the tray's contents have been removed.

The functioning prototype has proven to be quite robust, completing three million expansion/contraction cycles without noticeable fatigue. And while it was 3D printed, plans call for a marketable product to be commercially produced utilizing a more efficient, high-output technique, such as injection molding or roll-to-roll processing.

Ultimately, it is thought that the tray may be particularly well-suited to vehicles used in car-sharing services, where different drivers will have different preferences. The adaptive technology could also find use in things like personalized seat-positioning systems and self-activating sun blinds.

Source: Fraunhofer