Since the dawn of automotive, engineers have worked to make the chassis of a vehicle stiffer. Stiffness was the key to better handling, efficiency, and safety. Engineering blue pills for a car’s chassis were all the rage. Honda has now decided that more motion in the ocean is better.

Automakers routinely mention how much rigidity has been added to a chassis design with each new generation of a vehicle. Early box frames became ladder frames, adding more and more strength through improved materials and connections. Ladder frames gave way to unibody (aka unit-body) designs that, again, emphasized stiffness by combining the frame and body for more rigidity.

All of these changes were made to overcome the three basic sources of physical force on a vehicle: weight (components, occupants, cargo), torque twist (engine to axle twist), and lateral g-forces (turning, uneven surfaces). The logic has always been that keeping these forces from changing the vehicle’s frame shape was paramount. The ultimate goal being to keep the tires as flat to the ground as possible for predictable handling, steering, and braking.

That being the real goal of chassis design, Honda’s engineers decided to rethink how to accomplish it. Their solution was to add flexibility instead of more rigidity to the front portion of the vehicle’s chassis, using that flexibility to predictably push the steer tires to the ground through more than just suspension tuning.

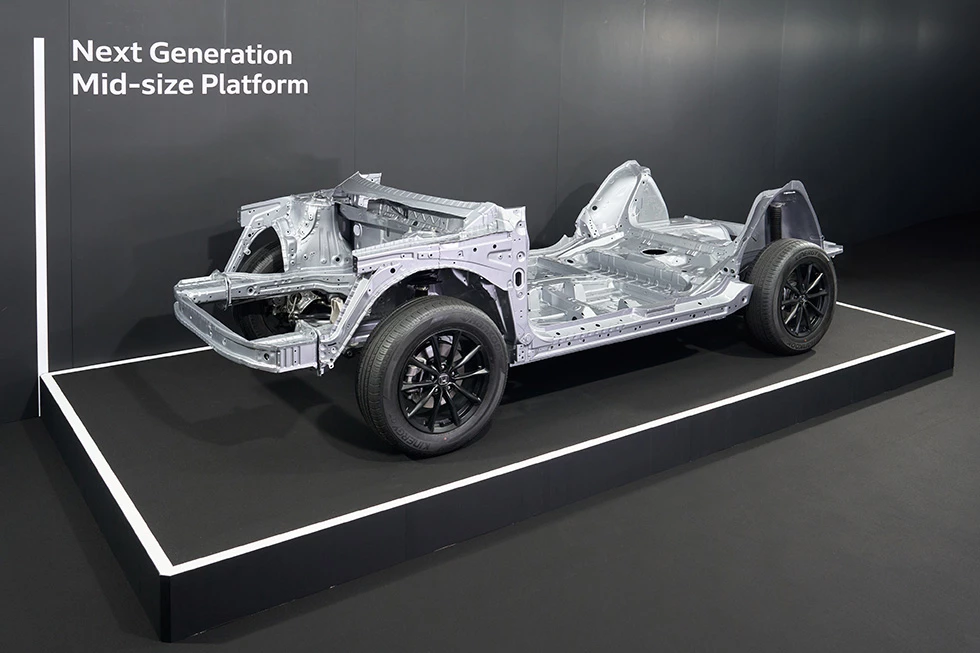

Honda’s new chassis will debut in 2027 as the company’s next-generation vehicle platform to underpin most of its popular models like the Odyssey, Civic, Pilot, CR-V and others, as well as several planned EV models coming soon. The platform is designed to allow about 60% parts commonality throughout its models and reduce the use of high-cost materials such as aluminum, while still light-weighting vehicles.

The basic engineering here is a great example of thinking outside the box to solve an age-old problem. The front structure of the chassis can bend and flex in response to high cornering or roadway forces, pushing the outer wheel of the turn down instead of out or lifting further than suspension would normally allow. This would not have been possible even 30 years ago, as tire design would not have allowed that kind of lateral movement.

Today’s tires, however, have improved beading and better belting to take on these kinds of forces. This calculated flex from Honda’s chassis design stays well within the safety margins of those tires while reducing the amount of suspension flex required to accommodate lateral turning forces.

The added benefits of this design include more input to the driver via the steering wheel, better interior comfort by controlling how body roll translates into the cabin, and better absorption of surface irregularities. Honda also claims that the new design solves much of the understeer creep that happens in front-heavy vehicles.

The new chassis design falls within Honda’s Advanced Compatibility Engineering (ACE) body structure for safety. Honda tests its vehicles in both Ohio and Japan for crashworthiness and says that this new chassis will surpass the current-generation platform for safety.

It integrates with the newly-developed pitch control technology that debuted as Agile Handling Assist in the new Prelude and Accord, and will debut with a new Motion Management System for vehicle stability control.

Source: Honda Global