With a slogan like “The Future is Ecclectic,” we’d expect some interesting things from INNengine, a startup based in Spain. The company is showcasing a “one-stroke” engine that works as an opposed piston with a wavy twist.

The “one-stroke” is in quotes as the engine is actually a two stroke (by definition), in that it has two movements (strokes) in its combustion process. Unlike most conventional two-stroke engines, however, the INNengine e-Rex doesn’t burn oil or even use one of those strokes to lubricate or cool itself. Those happen separately as they would with a conventional four-stroke automotive engine.

In those conventional engines, intake, compression, combustion, and exhaust strokes all take place separately. In a two-stroke engine, there is only compression and combustion, with intake/exhaust happening simultaneously with those. Two-stroke engines are generally more powerful for their package size and more thermodynamically efficient than four-stroke engines. But conventional designs are also dirty and (more often than not) noisy.

With the INNengine e-Rex, all of the advantages of a two-stroke engine are there, but the disadvantages are not. Making it a compelling option. It also outputs at one or both sides without much modification, which means it can be used to propel more than one axle easily.

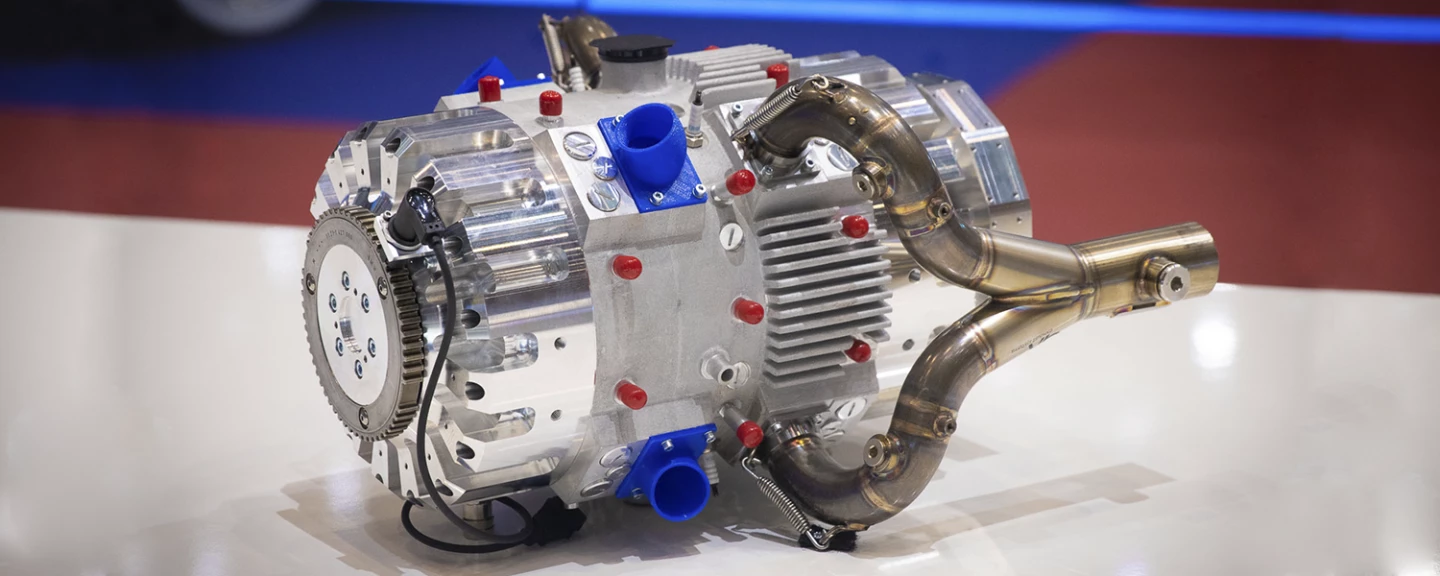

The INNengine design is an opposed piston setup in which there are four pistons on each side to make eight in all. The opposing pistons share a combustion chamber and have fixed rods behind them. These rods press on plates with an oscillating wave-like design so that the rods press and release the pistons in a smooth, coordinated movement. Intake and exhaust happens as it would with a two-stroke engine, with the exhaust port being just ahead of the intake port so that it leaves and begins creating a vacuum just as the piston moves past the intake port, to allow fresh air in for the next cycle. Fuel and spark are fed as they would be with any other piston-based engine.

This opposed piston setup makes for smooth operation with very low noise and vibration, while the packaging keeps the whole engine small. What’s more, controlling the gap between the pistons during compression by shifting one or the other end plate slightly allows for variable compression as well. Improving efficiency even more.

INNengine is showcasing its e-Rex design as a working prototype in a Mazda MX-5 Miata. The engine allows the car to become all-wheel drive and looks to take up about half the space (our assumption from visuals) that the conventional 1.8L engine occupied. It’s also far lighter in weight. Yet the 500cc e-Rex is said to be producing 126 horsepower, which is comparable to the 1.8L’s output. INNengine did not specify torque output and did not respond to answer that question before publication. It’s noted that their test engine did have a forced air setup on it. That is likely to boost the torque output, which we suspect is relatively low in a design like this given the lack of leverage from the pistons.

For this reason, we aren’t too sure about the INNengine e-Rex being capable enough to be a direct drive for most automotive applications. Despite this being what the company is trying to showcase. The engine might, however, be a very useful option as an efficient generator in a hybrid or range-extension option. Used in an electric vehicle, the INNengine could reduce the battery size requirement and offer lower weight and a better long distance driving option – especially if it can run as a multi-fuel option, which INNengine says it is capable of doing. Given that batteries are (and will likely long be) the heaviest and costliest part of an EV, that could be a boon.

Considering that the battery electric model of a vehicle is typically 30% heavier (or more) versus its standard gasoline combustion counterpart, this engine option could present a way to mitigate the safety and road wear risk associated by downsizing batteries in favor of an efficient combustion generator. Given that most people drive 30-40 miles (48-64 km) a day on average, this reduction in weight would not only give longer range to the batteries left on board, but it would allow the combustion to only be used when the vehicle is going further than normal. And it would make the car safer, as crash testing is showing that heavier vehicles mean more injuries for people in other vehicles in a wreck – and that’s an issue that’s very unlikely to go away anytime soon.

The INNengine e-Rex is an interesting innovation that could find a home in automotive. It’s also ripe for use in other sectors such as marine and off-grid power generation. A few questions about its capabilities still remain unanswered, but it’s one of the most interesting designs we’ve seen in some time.

Source: INNengine