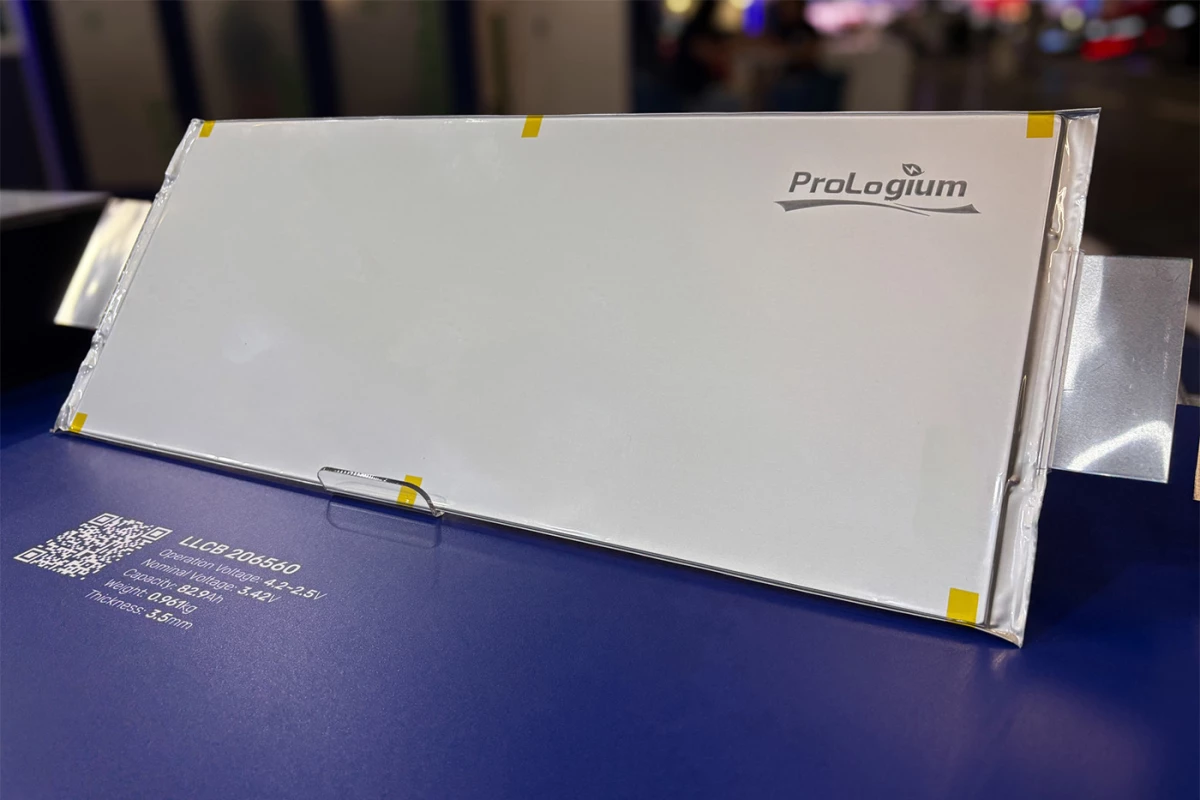

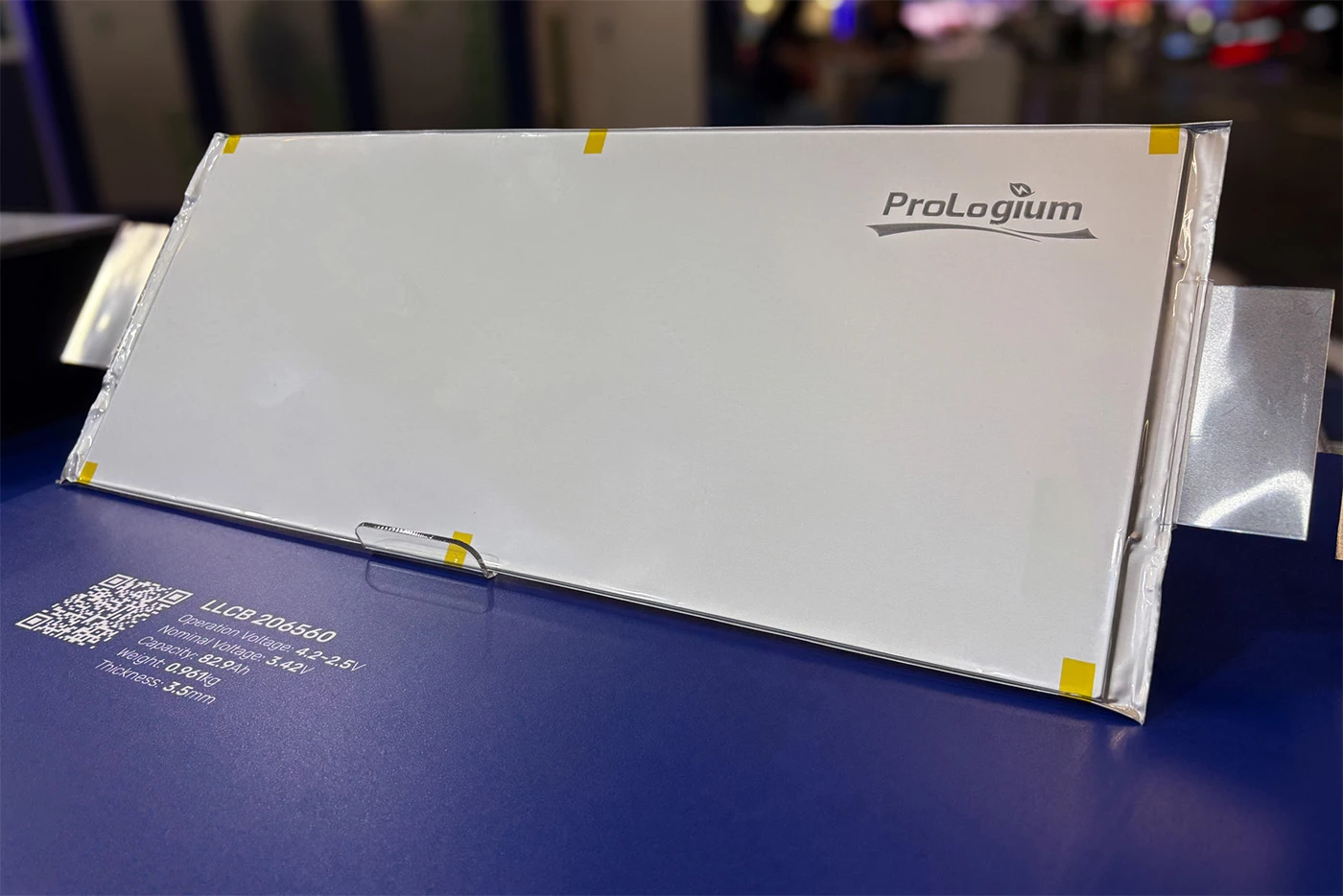

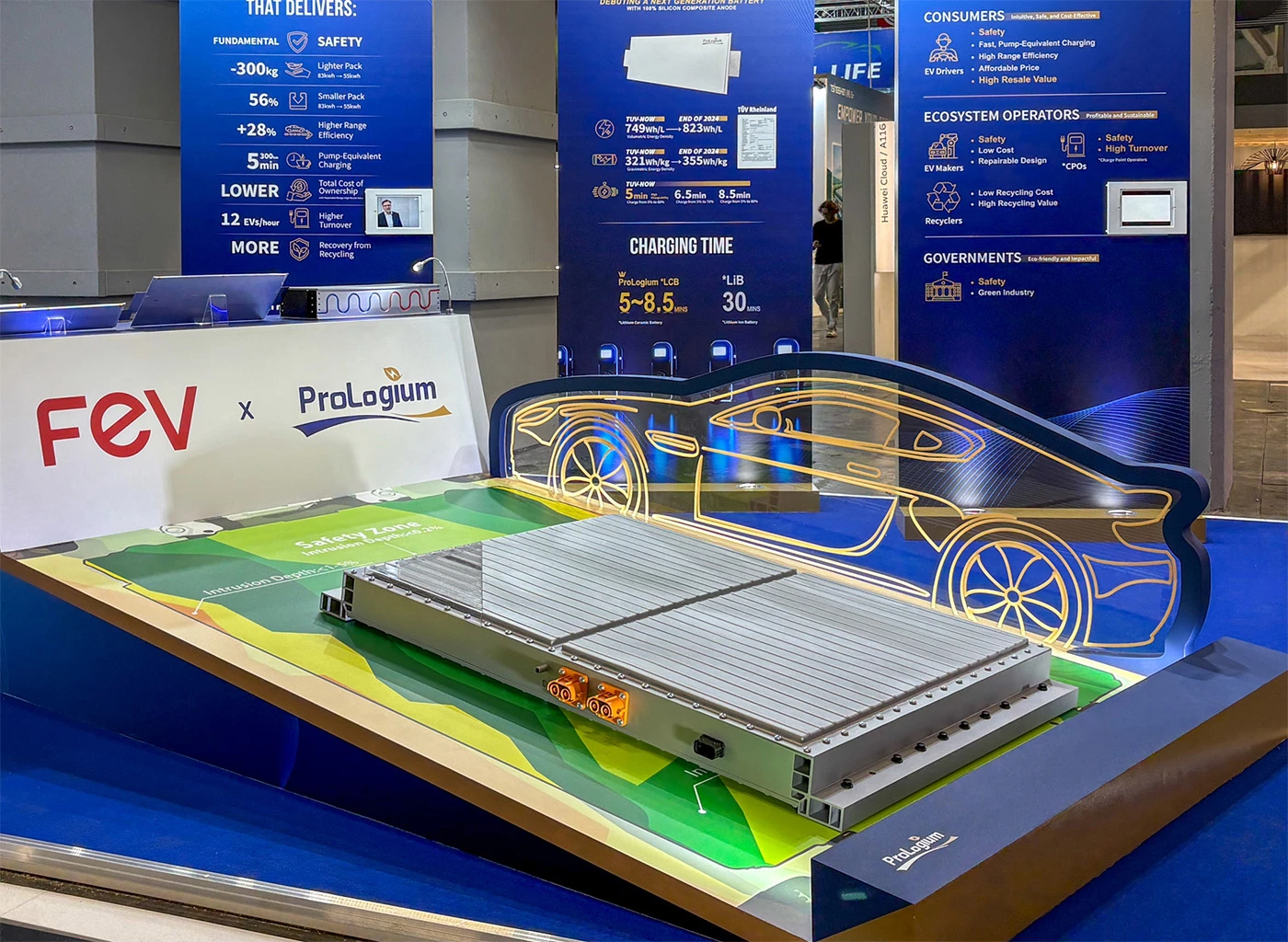

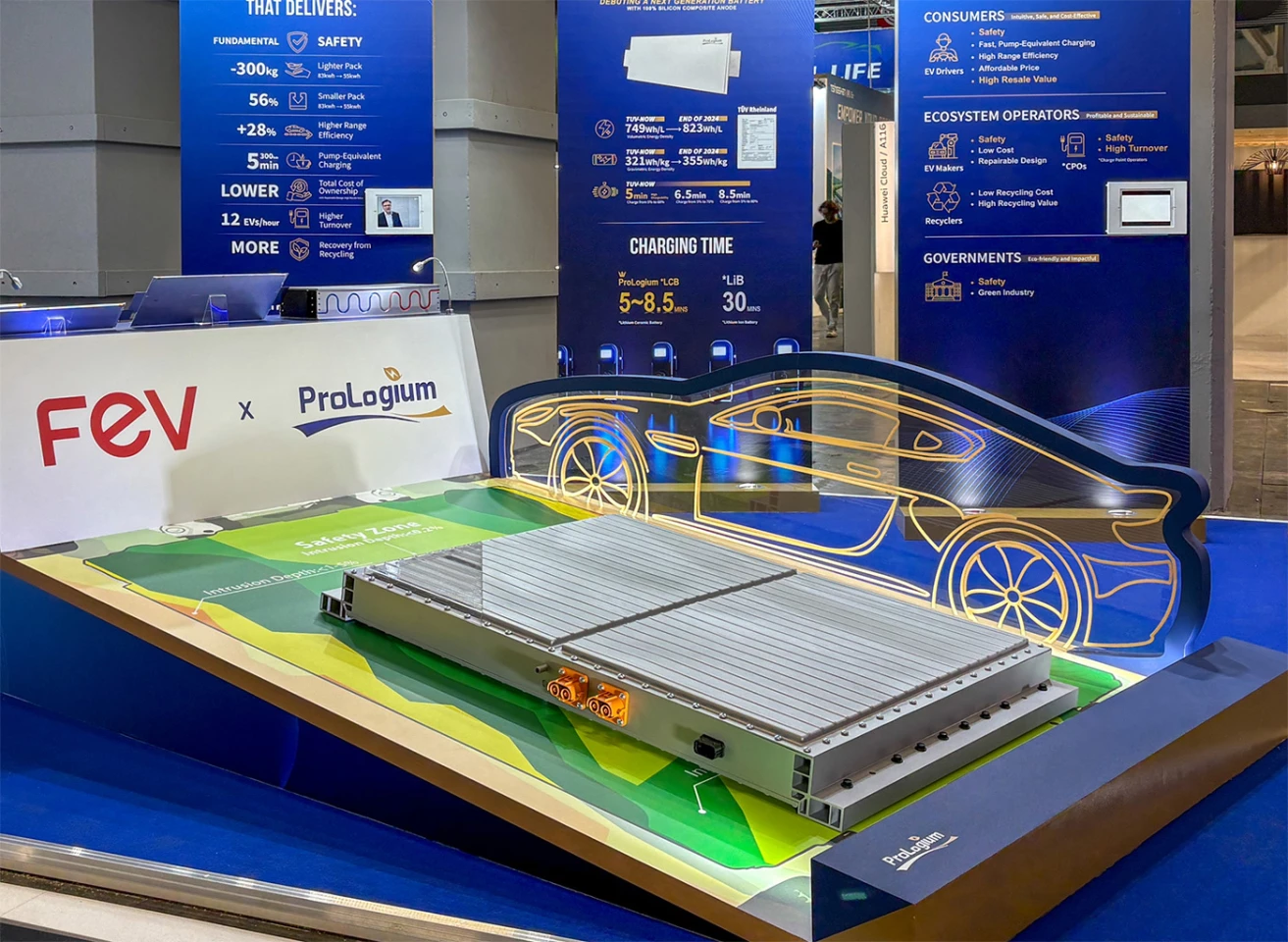

Battery tech firm ProLogium has taken the wraps off its 100% silicon composite anode battery. Highlighting its potential for use in EVs at the ongoing Paris Motor Show, the Taiwanese company claimed a major leap in energy density and charging efficiency, promising 186 miles (300 km) of range from a five-minute charge.

Let's dive into the juicy numbers right away. ProLogium said its new battery system manages an energy density of 321 Wh/kg. That's a huge leap compared to current electric vehicle (EV) batteries. For comparison, the 53 kWh battery pack in a Hyundai Ioniq 6 is rated at 153 Wh/kg, Tesla's superior 4680 cell is believed to come in at 232.5 Wh/kg.

This tech also charges awfully fast: it can go from 5% to 60% in just 5 minutes, and can reach 80% in 8.5 minutes. ProLogium highlighted how that's more than 80% faster than current EV charging tech on the market. That means it has the potential to solve limited public charging stations and long wait times while you're powering up on the road.

These batteries also feature a modular design, which should make them easier to repair and recycle – and hopefully bring down the cost of EV ownership in the vehicles they power.

ProLogium noted that it's also expanding from R&D into commercializing its energy solutions. It's partnering with German automotive drivetrain and tech firm FEV to begin manufacturing battery packs in the near future.

That sets the stage for serious competition in the race to deliver next-gen EV batteries. A couple of weeks ago, Panasonic noted its light and compact 4680 cells were set to go into mass production. And last November, Panasonic partnered with Washington-based Sila to use the latter's silicon anode tech to achieve a 25% increase in battery energy density.

Looking further into the future, there's a carbon fiber-based technology from Sweden that sees the battery doubling as the load-bearing material for cars. That makes it essentially 'massless,' since its weight doesn't add to that of the vehicle separate from its structure.

Given the growing need to make the switch from combustion-engine vehicles to EVs, we'll take all the range anxiety cures anyone can come up with.

Source: ProLogium