Utah's Transcend Energy Group claims it has a relatively simple and cheap way to dramatically increase the torque output of combustion engines, simply by replacing the standard connecting rods with new two-piece designs with a secondary joint.

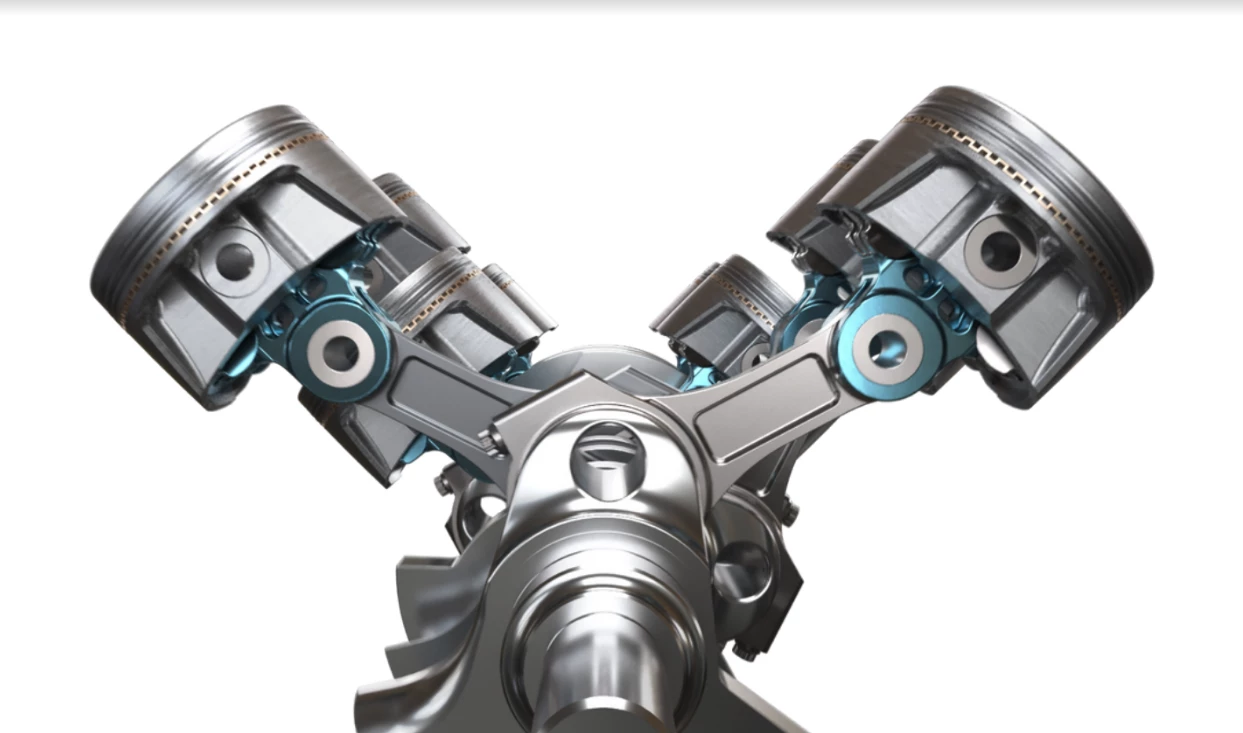

As the pistons in an engine move up and down, driven by expanding gases as the air and fuel burn, connecting rods, or con rods, transmit the linear force of the pistons into a rotating motion of the crankshaft. The small end links to a gudgeon pin in the back of the piston, with a bearing to allow it to change angle as the crank rotates, and the big end wraps around a crankpin so it can spin 360 degrees as the pistons push the crank around.

Transcend's "Thunder Rods" caused a bit of a stir at SEMA earlier this month. They add a secondary joint to the typical con rod design, sitting well below the gudgeon pin and outside the piston skirts. The company claims this arrangement makes the pistons drop farther and faster when the crank's at a 90-degree angle, delivering better leverage to the crankshaft and boosting "dynamic compression" by 25-30%.

Transcend tells Road and Track this effectively means the piston moves faster when it matters – when you're drawing air in through the valves, when you're compressing it, and when it leaves top dead center in response to gas expansion. And the company says the lower pin mount gives the piston more leverage on the crank. The additional speed and leverage create extra torque, particularly at low revs.

Transcend also claims that its two-piece con rods eliminate piston rock – this is a side to side tilting of the piston in response to lateral forces from the con rods; the piston and crank operate most efficiently upon one another when the crank's at 90 degrees, with the maximum possible offset between the crankpin and the big end, and the resulting lateral forces push the piston sideways into the cylinder walls. That's a problem, since it can wear the cylinders into an oval shape and unload the piston rings, causing a loss of compression.

In addition to the pin, the Thunder Rods actively engage the side walls of the piston using a pair of saddles with their own ability to rotate slightly. Transcend tells Road and Track these stop the piston from tilting and equalize pressure against the sides of the cylinder.

The company has only developed the rods as drop-in replacements for 5.3- and 6.2-liter LS V8 engines from General Motors thus far. In its own testing, Transcend says it was able to tune the 5.3 to match the torque output of the stock 6.2 – a leap of around 30% – between 1,500 and 3,500 rpm. Static compression in the 6.2-liter engine was raised from 155 psi to 198 psi, and the Thunder Rod-modified motor peaked at 32 degrees of timing, where the standard unit is best around 26 degrees.

Transcend says that while the LS is a popular drop-in engine for tuners, it's not optimized to take maximal advantage of the Thunder Rod design, and eventually the company hopes to see what it can do with purpose-designed cranks, cylinder heads and pistons.

While Transcend is confident, many are not convinced, particularly given the current lack of third-party testing and the paucity of results presented by the company. The two-piece con rods are heavier than standard items, creating additional inertial forces that will increase substantially as the engine revs faster, so there's a good chance that even if there are low-end gains, they might come at the expense of high-RPM horsepower.

And the design would also appear to create extra lateral force on the pistons, since the lower pivot point and shorter main arm make the angle between the con rod and the cylinder bore even greater. Not only that, but the distance between the main gudgeon pin and the new, lower pivot now effectively appears to become a torque arm that'll amplify the forces making the piston want to tilt.

So Transcend will certainly need to prove its con rods do what they say on the tin, and that they can do it without increasing engine wear. Either way, it's an interesting piece of engine tech that hasn't been used on gasoline engines before, even if it's similar in some ways to the crosshead con rods sometimes used in marine diesels and steam engines.

Check out a (short, silent, rendered) video below.

Source: Transcend Energy Group via Road and Track