Old SJ-series Jeep models are some of the most iconic American things there are. At Vigilante 4x4 in Texas, however, adding rubber-burning muscle and a whole lot of engineering makes them even more.

My day started in a motel lobby in Austin, Texas. I was looking for coffee. There was no coffee service in the room, which I should have researched before booking. That oversight on my part meant I was in reception hoping to score a java fix. They had a pot, but it was fresh out. By the time the front counter lady had made another and set it up for me, I was hearing the glorious sound of Mopar cylinders and beautifully-tuned stainless steel pipes. With no to-go lid for the coffee, I had to choose between drinking the bean juice or getting into a blue beauty of an early model Jeep Cherokee.

I chose the latter, dumping my coffee and jumping in.

Driving the rig was Daniel Van Doveren, co-founder of Vigilante and JeepHeritage.com. Originally from Belgium, Van Doveren transplanted to the German-belt region of Texas for love. Talking with him as we drove from Austin to his company headquarters in Johnson City, it became clear that for Daniel, the love of SJ Jeeps and his wife Rachel share his heart. Long love story short, he moved from Belgium to Texas for her, but he brought the #Jeepthing with him.

Arriving at the Vigilante shop, crunching gravel in front of a nondescript warehouse of a building, we walked to the door. There’s little to greet anyone here beyond the smell of old grease and rust and the sound of the breeze on metal buildings.

Directly inside the door is what one would find at any repair or disassembly space. A currently empty bay surrounded by shelves of removed parts of all descriptions: engine blocks, transmissions, a stray door, a couple of radiators awaiting further work, etc. Above, in a cramped, but surprisingly well-organized storage area, shelves and drawers of genuine Jeep parts from 1964-1991 models are stored by type. Window regulators, wheel caps, air intakes, chrome pieces, door handles.. You name it, it’s probably got a shelf here.

This is where the donor vehicles, all full-sized Jeep models from that magic SJ era, come to get torn down to their constituent parts. Pieces are cleaned, categorized, stored or restored here. The Van Doveren operation carefully catalogs and inventories them. This is the only dirty part of Vigilante and JeepHeritage, because it’s where the old is stripped away before being renewed.

The Vigilante Background

Before starting Vigilante, Daniel was in information technology working in Belgium. Jeeps were his passion, but not his career. He restored them as a hobby and still owns most of his personal fleet. This is evidenced in the shop, beyond the dirty parts. “I liked restoration work and it was popular enough [in Belgium] to have clubs where friends would get together to help each other restore them,” Daniel said. Vehicles like the Cherokee, Grand Wagoneer, Comanche, and original Gladiators are popular in some European circles. “Great care is taken in restoring them,” he said.

In America, however, they are only recently popular as classic restorations. “I would come here as part of my work,” Daniel explained, “and see them rusting or only partially restored. I learned that the enthusiasm for them here was small.” Everyone seemed more interested in Corvettes and Mustangs and old Detroit pickup trucks instead. Those who did do SJ restores were often doing it for love alone. In that, Daniel could relate.

During one of those trips, he met Rachel. “I was in a hotel bar thinking about my career,” Daniel mused. “Then she sat next to me. It was the only stool left. She was on her way to a concert. We talked.” The spark happened, but didn’t flame until later. Heading across the globe to his home, Daniel nevertheless got Rachel’s number before she left to see Blue Oyster Cult and he got on a plane.

Not long after, he returned to Texas, having decided to move and start a new business. He began what would become JeepHeritage.com and learned that someone was selling an operational Jeep Wagoneer in Georgia. He called Rachel and asked if she wanted to road trip.

“I barely knew this guy and he wanted me to take a multi-day road trip to buy an old Jeep.” Of course she said yes. “He had (and still has) a beautiful yellow Honcho. I love classics and grew up around them.” Very soon, she was all-in. Now the two run JeepHeritage.com and Vigilante4x4.com together. It was a definite match and even now, years later, their love is obvious. For each other and the Jeeps.

The Process at Vigilante

The bulk of the Vigilante shop is clean concrete and white walls with black steel girding. Arrayed throughout are Jeep models in various stages of restoration, upgrade, and detail. Daniel’s Honcho as well as a work-in-progress Jeepster and a Wrangler Renegade occupy one corner; all personal projects of his.

The rest are client vehicles or vehicles getting prepared for sale. Restoration work via JeepHeritage is done meticulously, carefully keeping every part as original as possible. Restomod work for Vigilante is a more complex engineering process.

Near Daniel’s personal projects are bare frames on wheels. This is where everything begins. These frames are custom-designed by the Vigilante team, made to handle the added power output of the modern muscle they’ll receive. The design is modular and can be changed to match the slight changes required of one body versus another – or one engine versus another.

The engines to be used are Mopar crate engines. Generally 6.4- and 6.2-liter V8s such as those found in SRT and Hellcat models. There has been one V10 Viper engine used as a custom one-off for a client, but Daniel says that’s not something he makes a habit of. “That was a good challenge,” he said, “but not what most people really want. These are factory crate engines with warranties and electronics and no modifications. Any Dodge dealership can do maintenance for them.”

Bodies from donor vehicles are disassembled and cleaned in the dirty room. Then packed into crates, on rolling sleds, and shipped to Italy. “I have a long relationship with a family there who do excellent work. All metal, no filler or resin.” Three vehicles can fit into one cargo container and the cost to ship is surprisingly low. The Italian family will repair, clean, straighten, and nickel plate the bodywork. Then custom paint according to Vigilante’s specifications, usually dictated by the client or Daniel’s design team. Then they are shipped back.

As the bodywork and paint is being done, the frames are made and painted. In the shop, the Vigilante team begins installing the engine, fuel system, and mechanicals in preparation for the body’s return. Outside of the bodywork and frame build, most everything else is done in-house.

Each station has a lift and is currently occupied by a vehicle in process. A nearly finished Wagoneer, whose upholstery is complete and whose audio and other interior components have been installed, undergoes final tuning and programming. It will road test soon. Across from that, a Cherokee Chief awaits interior finish and details as its seats and carpeting are prepared for install. Not far away, a newly-restored body has been bolted to its new frame and chrome and other pieces are being added, along with some custom detail paneling. The upholstery is currently in process.

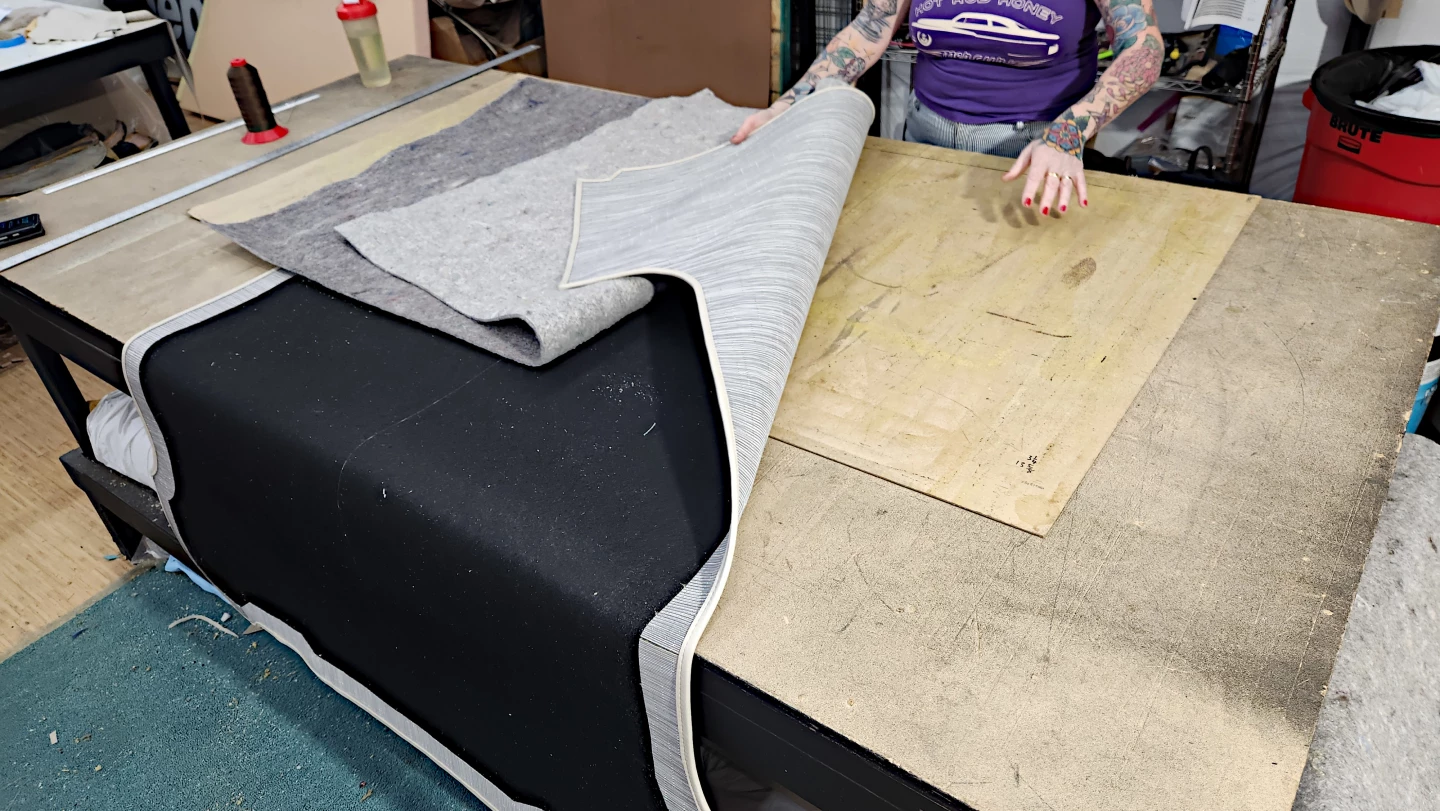

Upstairs from the shop, in a clean room segregated by clear plastic, is an upholstery room. A tattooed English woman named Liz works an industrial sewing machine and upholstery tools, taking the original seats and remaking them into clean, new, and often custom units for reinstall once the vehicles are ready. She does both restoration and restomod models. Restorations for JeepHeritage often use original 1980s and 1990s upholstery scored at auction when old dealerships or inventory are sold. Restomods usually get new, sometimes custom upholstery, including one recently finished using sheepskin and wool.

Straight below Liz’s upholstery is a station where both wiring harness and CAD work is done. Boxes of completed wiring harness sections sit on shelves to one side and a computer and 3D printer for modeling sit atop a desk nearby.

Details Are Key at Vigilante

The real work, though, is in the details. Daniel and his team have 3D-scanned and designed parts of every description. Old-style radios with new-tech insides are used. Dashboards and center consoles are remade and replaced in Vigilante vehicles to accommodate the needs of the unmodified Mopar power units they’re to work around. Gauge displays are completely new, but you’d never know it looking at them. Careful attention to keeping the old-style look and feel has been made in all of these tangibles.

Underneath the dashboards, ductwork and heater core housings have been designed to work with modern HVAC. Other changes such as the swapping of a cigarette ashtray for an air duct help improve comfort in the vehicle are standard. Even the chrome strips that used to hold down the carpeting in the cargo space are replaced. This time with authentic-looking, but much sturdier aluminum strips. Speaker covers, seatbelt guides, door handles.. Everything is made to be perfect.

“The engine swap and simple restomod changes most shops make are not hard to do. Our clients come to us because we go beyond that. It’s these details that make us what we are,” the Vigilante co-owner stated as he showed me a swatch of vinyl woodside prints he’d had made. These were his guide as he looked for the perfect replacement for the usually degraded or missing woody panels of old. It’s that kind of attention to detail in JeepHeritage restoration work that led to Vigilante’s attention to detail in its modifications.

And throughout the shop, that’s what most everyone was doing. Looking at and working with details. Dropping an engine onto an open frame is relatively simple. Aligning and balancing a drive shaft requires a little more attention to detail. Each build is unique because each customer is unique. Superficial things like color or motif are one thing, but some of Vigilante’s clients are very specific about interiors, audio systems, or even tuning specifications.

The graveyard of donor vehicles behind the Vigilante shop is a testament to the work being done here. Jeeps in various conditions line up in the weeds. Some are missing major components, some are only partial vehicles, others have no drivetrain or axles. Individually, many were likely headed for the crusher if they didn’t just rust away wherever they were sitting before. Here, they get new life. Some are good enough to become JeepHeritage restorations. Some will be parted off to make Vigilante4x4 restomods. All of them are going to be something again.

The work being done in Johnson City is not your average hot rod shop’s builds. These are six-digit machines and it shows. Love, details, and teamwork. That’s what Vigilante 4x4, JeepHeritage, and the Van Doverens are all about. It’s a beautiful thing.