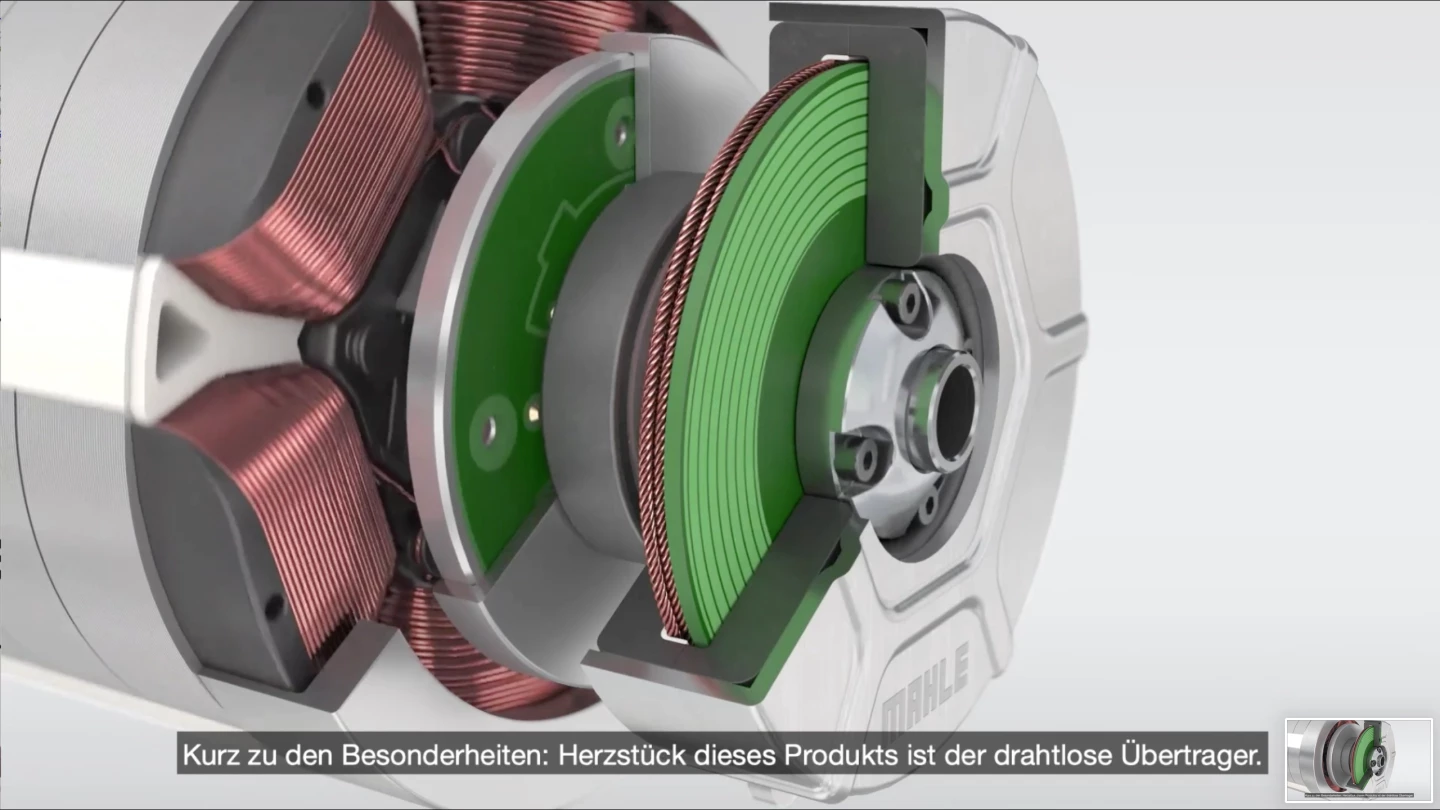

Several companies around the globe have been hard at work innovating and refining magnet-free electric motors to make them a more viable option for the fast-growing EV industry. ZF Friedrichshafen has taken a similar wireless inductive path to fellow German automotive supplier Mahle, but with its own unique configuration. By integrating its inductive transmitter into the rotor itself, ZF saves space and creates a particularly compact magnet-free motor it says performs comparably to the permanent-magnet synchronous motors (PSMs) that dominate contemporary EV engineering.

By swapping out the magnets on a motor's rotor in favor of electrical windings, manufacturers can eliminate the cost, ecological damage and potential supply chain disruption involved in the mining of rare-earth materials needed for those magnets. However, traditional magnet-free designs introduce added physical elements like the sliding rings or brushes needed to run electrical current into the rotor windings, adding size and weight while introducing more friction and potential for wear and tear. So EV makers tend to go the path of least resistance – literally and figuratively – relying on permanent-magnet motors.

Contactless induction is one promising solution that sends electricity to the rotor coils without physical brushes or rings, eliminating the disadvantages thereof. To further this tack along, ZF has integrated its inductive transmitter inside the rotor shaft at the center of the coils, eliminating the extra 3.5 inches (90 mm) of axial space it estimates physical solutions like brushes take up, while offering power and torque density comparable to a PSM.

ZF calls this design the In-Rotor Inductive Excited Synchronous Motor (I2SM), and the idea is that an automaker could replace a PSM with this new type of motor without sacrificing anything in terms of packaging or output. ZF further says that at continuous high-speed operation, such as when driving on the highway, the I2SM will operate more efficiently than a PSM.

ZF's inductive transmitter does look to be more compact than alternatives such as Mahle's (below), which uses two larger-diameter discs around the outside of the rotor shaft. Of course, it's impossible to compare the two prototypical systems in a definitive way, or to make heads or tails of ZF's "world's most compact and torque-dense e-motor without magnets or rare-earths" claim based merely on initial illustrations. We'll need to wait for concrete specs like dimensions, weight and output numbers for that.

For now, ZF says it plans to continue development toward production maturity with the aim of integrating the I2SM units into 400-V and 800-V electric drive platforms for supply to passenger car and commercial vehicle manufacturers. It revealed its initial I2SM work at this week's IAA Mobility Munich show.

ZF animates the motor tech below.

Source: ZF Friedrichshafen