In this transitional period between the gasoline and electric ages, there's still plenty of room, and plenty of motivation, for last-gasp improvements to the combustion engine – and a Swiss R&D facility says its electro-hydraulic, fully variable valve system is already delivering up to 20-percent fuel consumption reductions in testing.

European Union emissions standards were first brought online in December 1992, and precipitated an enormous shift in the automotive industry. Every five years or so since then, this incredibly influential set of standards has ratcheted down tighter on automakers, forcing them to find ways to reduce harmful exhaust emissions and squeeze more out of a drop of gasoline while simultaneously meeting the market's demands for power and performance to be uninterrupted.

Obviously, fully electric vehicles are the gold standard when it comes to tailpipe emissions, but next-gen batteries seem to be taking longer than anyone expected to hit the market, and the transition to the EV age is taking its sweet time, so at the time of writing, the internal combustion engine seems to have plenty of legs left on it, as well as pressure coming from all directions to boost power, efficiency and responsiveness while reducing emissions.

The idea of replacing the camshaft-driven valve train, which more or less locks in the opening times, closing times and lift measurements of intake and exhaust valves, is getting plenty of attention as a promising way to achieve these goals. Crude, mechanical variable valve timing efforts like Honda's VTEC and Hyundai's recently announced Continuously Variable Valve Duration system can get us part of the way there, but to get the most out of the technology you need to completely separate the valves from the crankshaft and achieve fully electronic control over exactly when each intake or exhaust valve opens and closes, and how far it's opening.

And these efforts are underway. Ultra-exotic automaker Koenigsegg has been working on its electro-pneumatic Freevalve system for several years now, and is preparing to launch a hybrid hypercar in 2020 with an electronic valve system that's completely uncoupled from the crankshaft for total freedom of timing and valve lift. We spoke with British company Camcon Automotive last year, which had achieved something very similar with an electrically actuated desmodromic, or fully mechanical system.

And now, a Swiss research team has announced "completely free adjustment of stroke and timing" on a valve train that uses electro-hydraulics to push its valves around. Empa is a Swiss government research institute for applied materials sciences and technology. Based in Zurich and founded in 1880, it now employs around 1,000 scientists working across a wide range of projects.

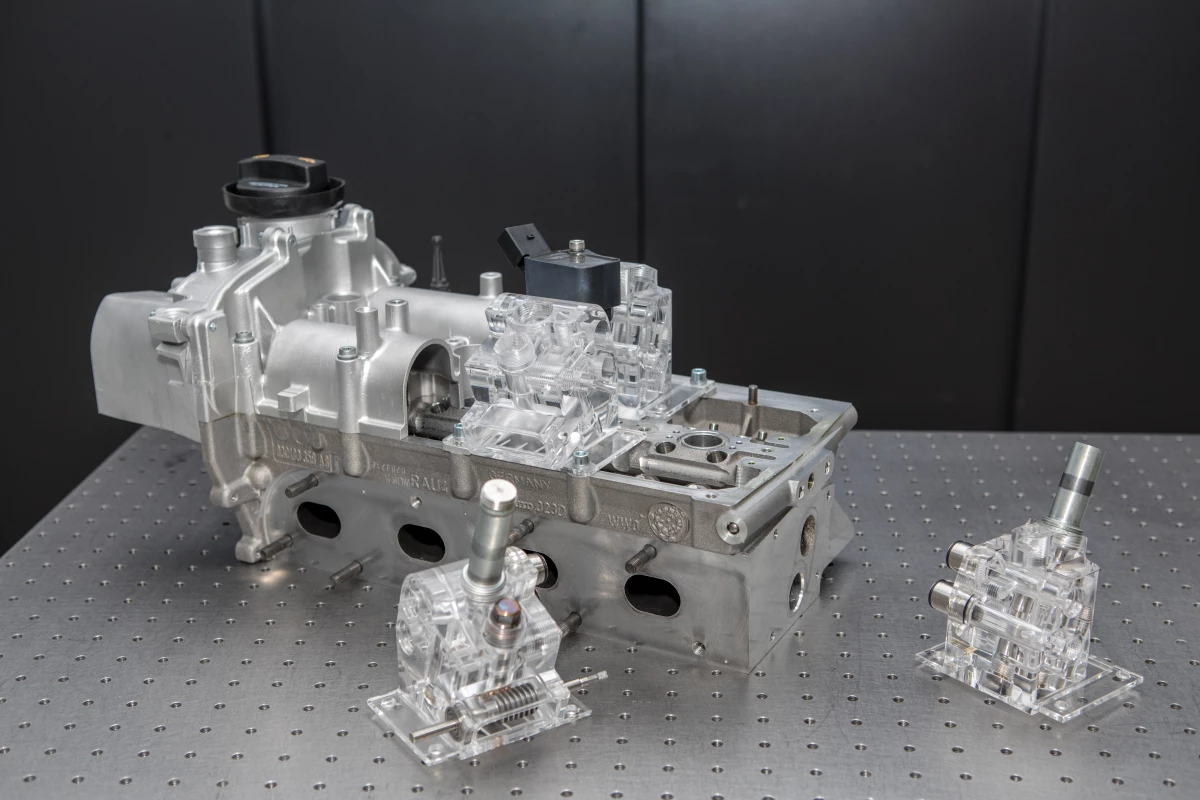

This Empa team has been beavering away on a way to make a digital valve train that's reliable, robust and cost-effective enough to push out into series production well under the hypercar price bracket, and it claims its FlexWork device is a strong candidate for the job.

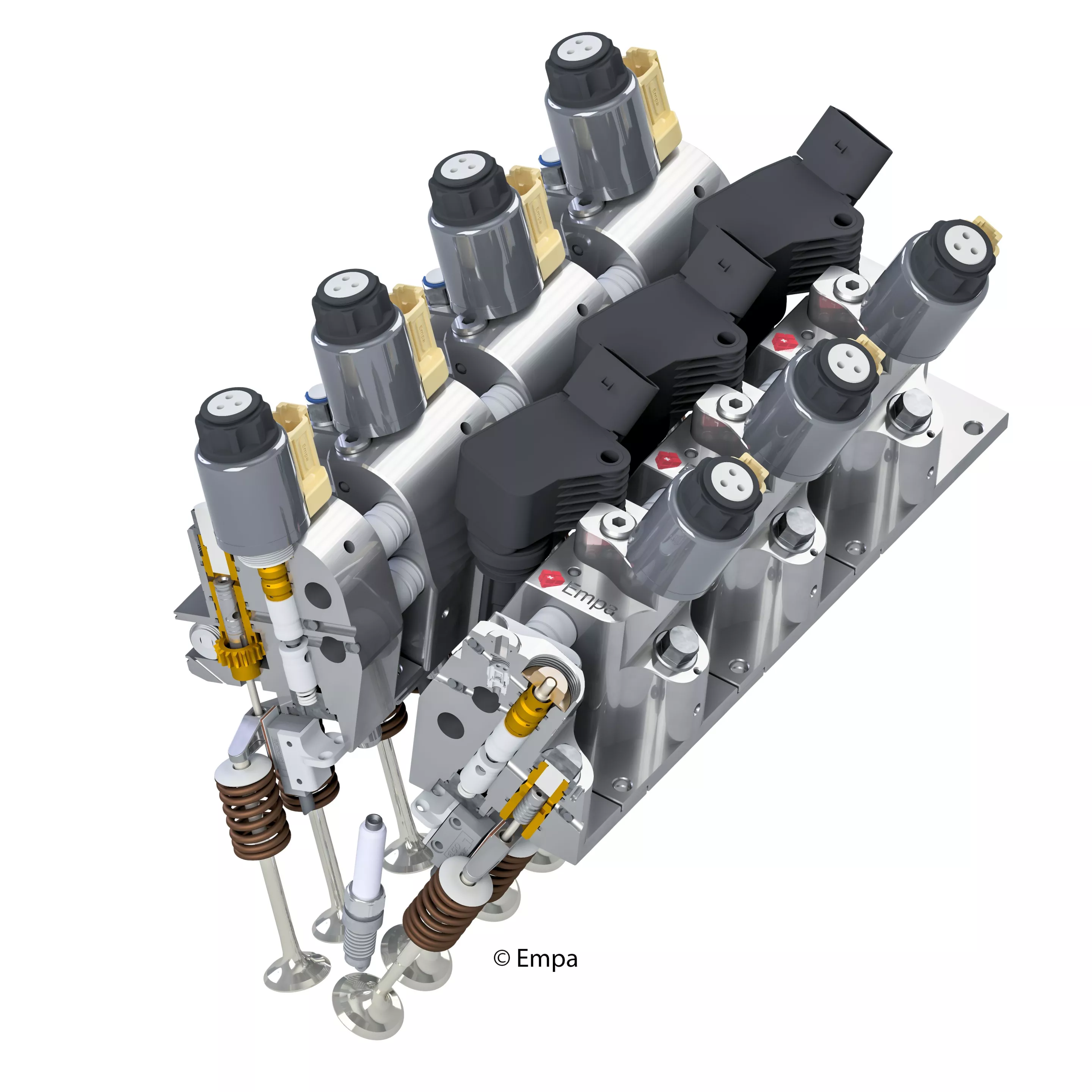

In the FlexWork system, valves are electrically controlled through solenoid coils, which open their own miniature valves and allow a hydraulic fluid as simple as the water-glycol mix you use in your radiator to push the engine valve open to the desired degree against a spring. Opening within milliseconds of the request being sent and closing at the speed of the valve springs, the system loses little energy in the process, as the spring returns most of its force to the hydraulic fluid when it's released.

The team has tested FlexWork using a modified Volkswagen 1.4-liter TSI engine, which was fitted with the new valve system and run on natural gas. It's been running on the test bench since October 2018, and the team says it's performed flawlessly, achieving "a significantly lower energy requirement over a wide operating range compared to camshaft-driven systems." In typical low-load tests emulating passenger car driving conditions, the team says the FlexWork motor uses about 20 percent less fuel than a similar motor with a conventional valve train.

Perhaps most importantly, the team says FlexWork "needs only low-cost components. No expensive, very fast switching valves and no complex sensors are required," and Empa is already in discussions with a number of engine manufacturers to commercialize the technology.

In addition to boosting efficiency, digital valve technology can also be used to increase power and torque, shut down one or more cylinders during highway cruising, or make an engine capable of operating across a variety of different fuel sources. The team says it's also looking into the potential of alternative combustion concepts, including homogenous self-ignition, in which "a fuel-air mixture is ignited at the right moment without ignition sparks by setting the correct conditions towards the end of compression. The mixture is combusted almost without pollution." That certainly sounds promising.

Indeed, since fully digital valve systems are very recent technology, it's hard to say exactly what might come out of them once engines start being specifically developed to make maximal use of this kind of tech. But it seems they'll be out in the market sooner rather than later, and this is an area to keep your eye on.

Source: Empa