Starting with adhesive tape and incorporating some advanced laser techniques, scientists at Rice University have developed a promising new electrode material for a battery architecture with massive potential. The team’s breakthrough could help overcome a long-standing problem with lithium metal batteries, a technology that promises to significantly improve on the performance of today’s solutions.

Lithium metal batteries are batteries in which the graphite traditionally used as the anode (one of the two electrodes) is replaced with pure lithium metal. Because this material offers very high energy density, lithium metal could make for batteries that charge much faster, and offer as much as 10 times the capacity.

But there are a few roadblocks standing in the way, one of which is the troublesome formation of tentacle-like protrusions called dendrites. These form on the surface of the anode during charging and can cause the battery to short circuit, fail or catch fire, so a great deal of battery research focuses on snuffing them out.

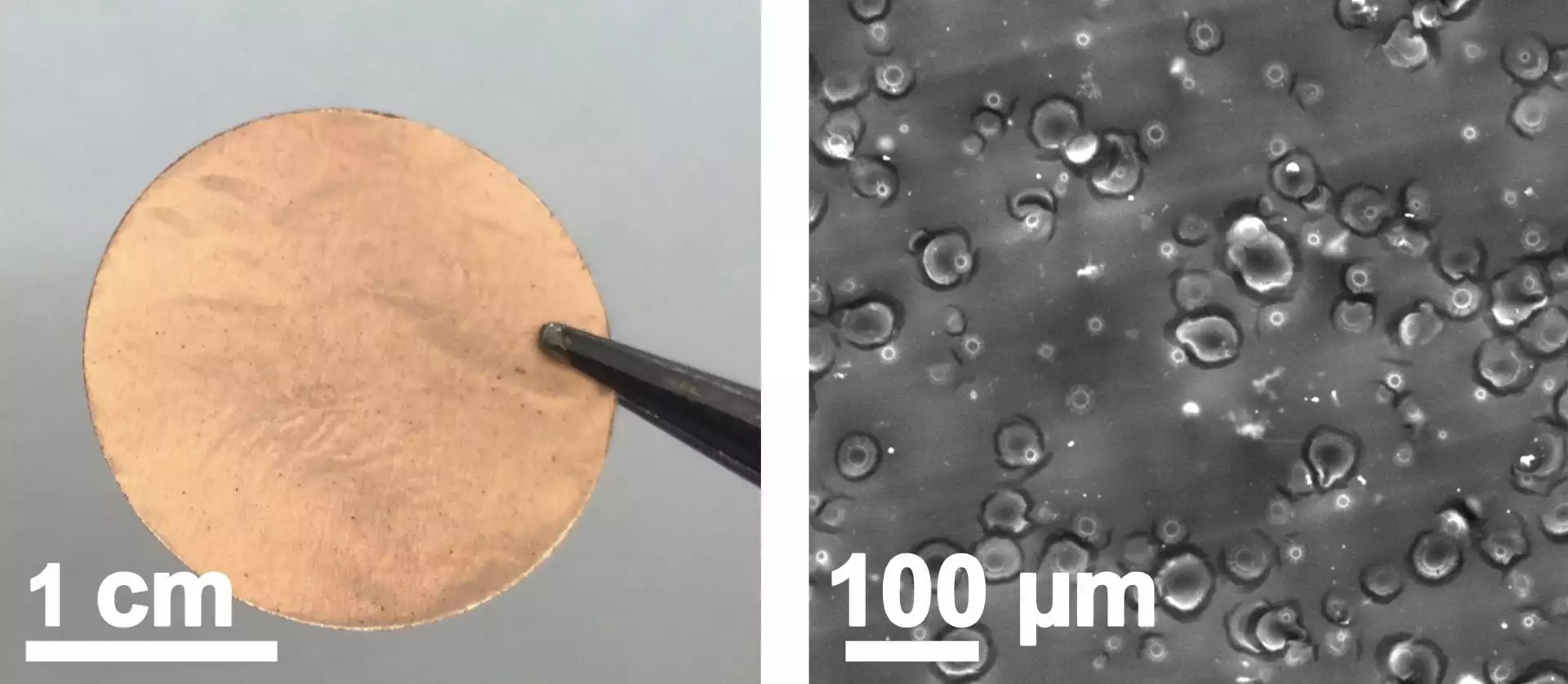

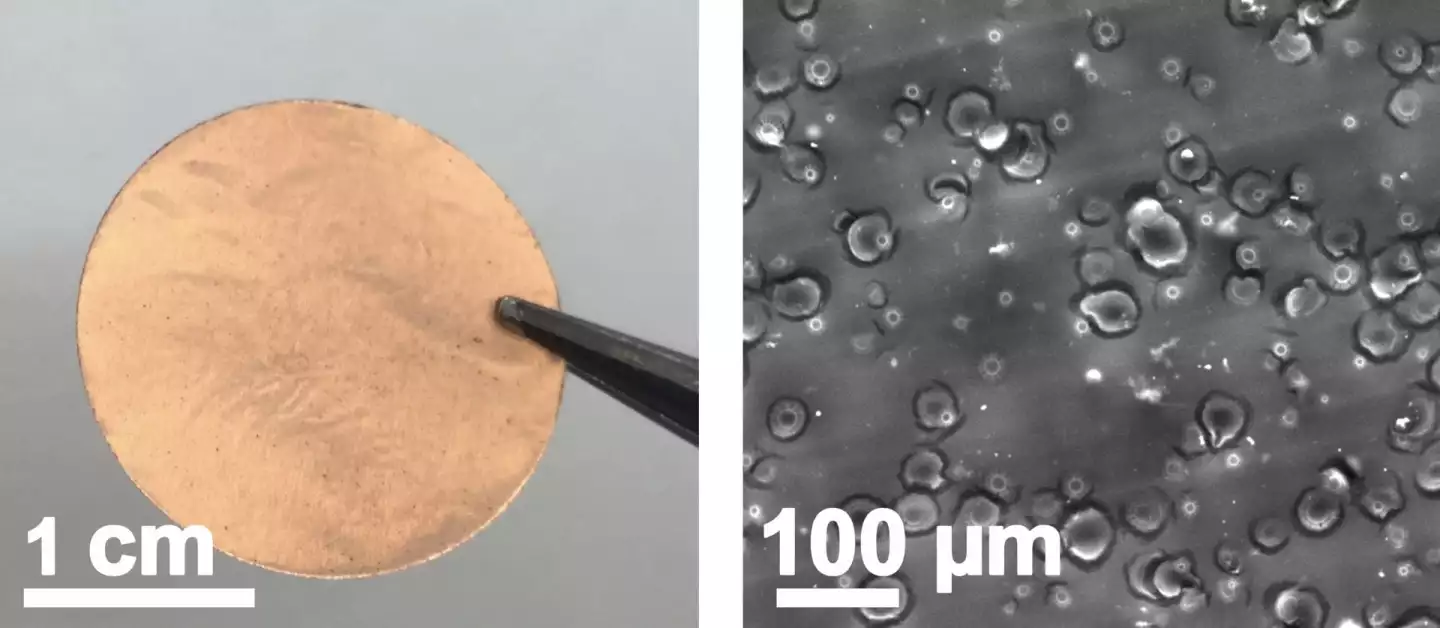

The latest breakthrough in this area comes from Rice University researchers, and begins with a strip of adhesive tape. The team applied the tape to the copper current collector that forms part of the lithium anode and treated it with lasers to heat it to an extreme temperature of 2,300 Kelvin (3,680 °F or 2,026 °C), which afforded it some very useful new properties.

This process transformed the tape into a porous coating made mostly of silicon and oxygen, along with small amounts of the wonder material graphene. Initial experiments with the film showed that it can serve as a protective layer on the current collector component, both absorbing and releasing lithium metal without giving growth to the harmful dendrites.

One of the consequences of replacing graphite with lithium metal anodes is an increased oxidation on the surface which greatly shortens their life, something researchers have looked to compensate for by adding excess amounts of lithium. There are positives to leaving it be, however.

“When there is zero excess lithium metal in the anodes, they generally suffer fast degradation, producing cells with very limited cycle life,” said co-author Rodrigo Salvatierra. “On the bright side, these ‘anode-free’ cells become lighter and deliver better performance, but with the cost of a short life.”

In its laser-induced silicon oxide protective coating, the Rice University team may have found a way to leverage these positives without the added burden of excess lithium. Its experiments showed that batteries fitted with its new coating exhibited triple the lifetime of other “zero-excess” lithium metal batteries, retaining 70 percent of their capacity over 60 charge and discharge cycles.

The team describes the technique as fast and safe, involving no solvents and able to be carried out at room temperature. It therefore has high hopes for its potential to be scaled up.

The research was published in the journal Advanced Materials.

Source: Rice University