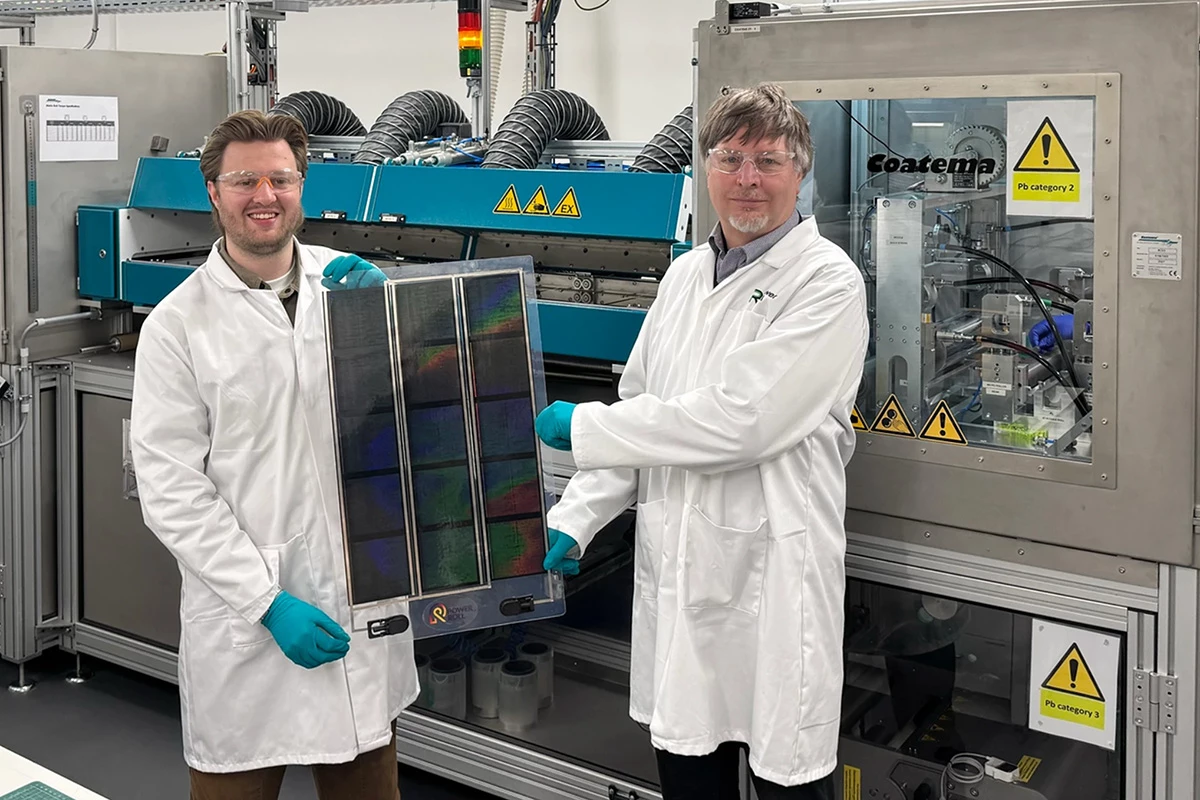

Since 2012, UK-based Power Roll has been working on a way to print low-cost solar film to generate clean energy from sunlight. It's now one crucial step closer to manufacturing its lightweight, apply-anywhere film, with a new design for its perovskite solar cells that should make make production cheap and scalable.

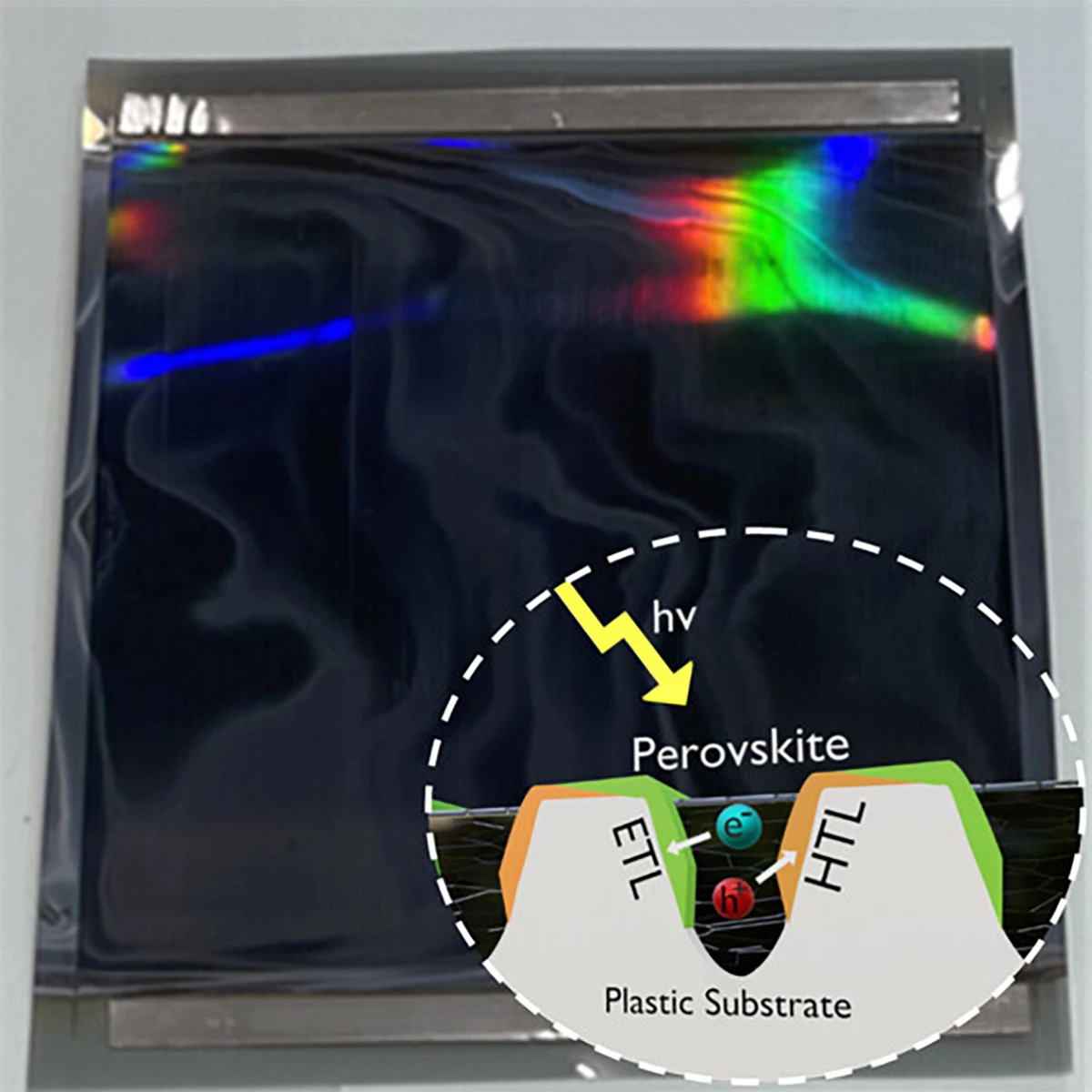

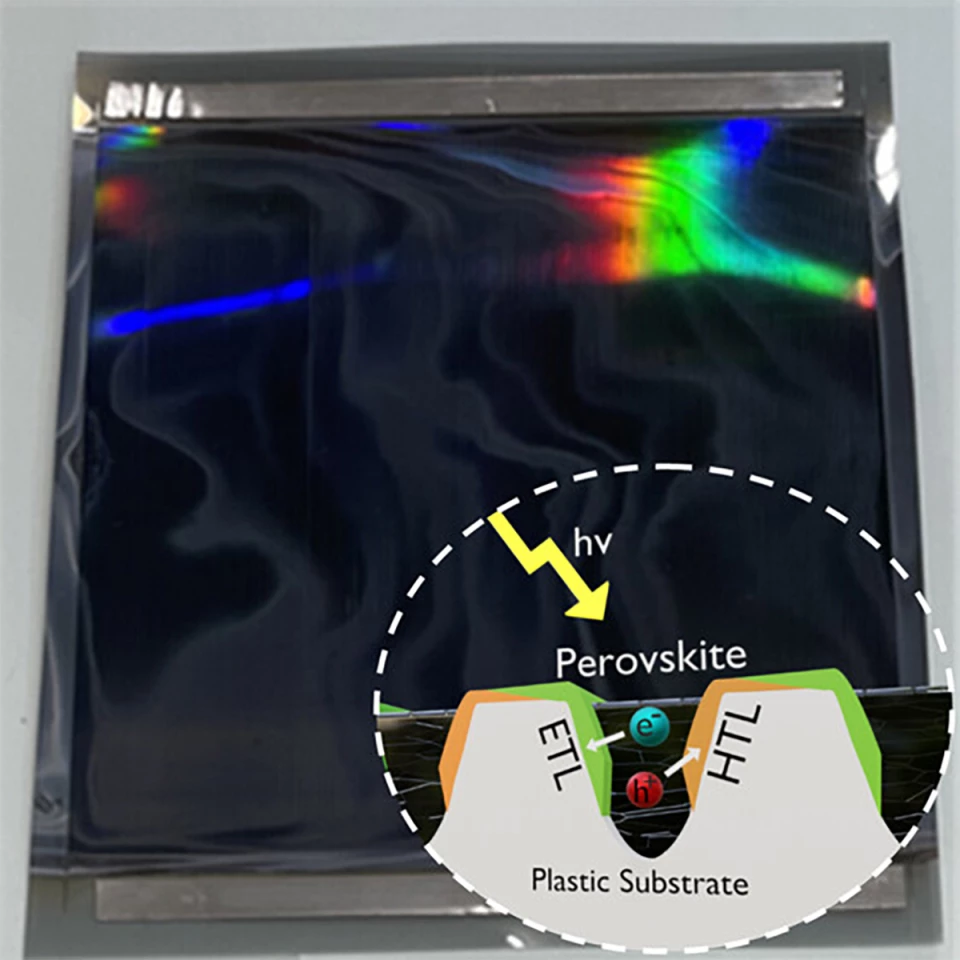

Power Roll has been focusing on embossing 'microgroove structures' into a plastic substrate, similar to a "hologram" on a credit card. A single square meter has 500,000 microgroove structures, and these are coated with conductive materials and photo-active ink. Layers of encapsulation film keep the printed rolls stable and enhance their durability.

This is all carried out using what's called roll-to-roll processing, where you coat or emboss an entire length of a material that is fed continuously from one roller on to another. It's inexpensive and efficient. In addition, Power Roll is going with abundant perovskite as a key material in its solar cells to absorb sunlight and convert it into electricity.

The company has already been at this for a while and has loads of patents to prove it, so what's new?

Essentially, the team, in collaboration with researchers at the University of Sheffield, has devised a new microgroove structure with a back-contact format – with all the electrical contacts of the solar cell on the back rather than in front. This not only allows for more efficient energy generation, but also makes it cheaper and simpler to produce the solar cells.

The new design also increased the number of grooves in each component of the back-contact perovskite solar cell, from 16 to 362. That improved power conversion efficiencies (PCEs) by up to 12.8%.

The group also used a Hard X-ray nanoprobe microscope to check the structure and composition of the solar cells for defects. The detailed images helped identify issues like empty spaces within the semiconductor material.

This back-contact design of the solar cell allows the perovskite to directly absorb the light without it first passing through a transparent conductive oxide (TCO) layer. That negates the need for TCOs incorporating rare and expensive materials like indium, and as such, brings down the cost of production.

The big deal about its product is that this solar film is awfully light and easy to apply. That means you can install it on all kinds of surfaces including non-loading bearing rooftops, transport it to remote areas that need accessible options for generating electricity, and hopefully, blanket many currently unproductive buildings and spaces with it so you've got many more sources of clean energy to supply the grid. Power Roll has a neat visualization of this optimistic vision in its promo video below.

With that, Power Roll is set to scale up manufacturing of its solar cells sharpish. The company and its collaborators at Sheffield have published these advancements in the production process in Applied Energy Materials. The team working on this will move on to explore the use of X-ray microscopy in better understanding how its film will operate and what sort of stability it will exhibit.

Last October, Power Roll raised US$5.4 million in a funding round to grow its fully operational manufacturing plant's production capacity. It's also expecting to produce enough of the solar film to generate 1 GW of electricity in the near future.

Source: Power Roll