Hybrid "power capacitors" that can store as much energy as lithium batteries, but with much higher charge/discharge rates, a huge range of safe operating temperatures, super-long lifespans and no risk of explosion are already in production, says a small Belgian company that's been testing them and selling them for some time.

Chinese family-owned company Shenzhen Toomen New Energy is tough to find, at least on the English-language internet, but Belgian electronic engineer Eric Verhulst bumped into Toomen representatives on a tiny stand at the Hannover Messe expo in Germany back in 2018, while looking for next-gen battery solutions for an electric mobility startup he was running.

The Toomen team made a hell of a claim, saying they'd managed to manufacture powerful supercapacitors with the energy density of lithium batteries. "Of course, that's an unbelievable claim," Verhulst told us. "It's a factor of 20 better than what, for example, Maxwell had at the time. So I took my time, went over there, looked at their tests, did some tests myself, and I got convinced this is real. So at the end of 2018, we made an agreement to become their exclusive partner."

According to Verhulst, when he and his team got these "power capacitors" into the lab, they performed even better than they looked on the spec sheet. He tried to break them with charge and discharge rates up to 50C, more than double their rated capacity. They refused to fail. He left them fully charged for months at a time, and found them still well charged when he picked them up again. The University of Munich tested and confirmed their ability to handle temperatures down to -50 ºC (-58 ºF) and up to 45 ºC (113 ºF) without any heating or cooling systems.

And their energy density was extraordinary. The highest density cells were getting between 200-260 Wh/kg, every bit the equal of today's leading commercial lithium batteries but with a higher charge and discharge rate, and no risk of explosion. The power-focused variants were delivering densities of 80 and 100 Wh/kg, and were charging and discharging at 10 and 20C.

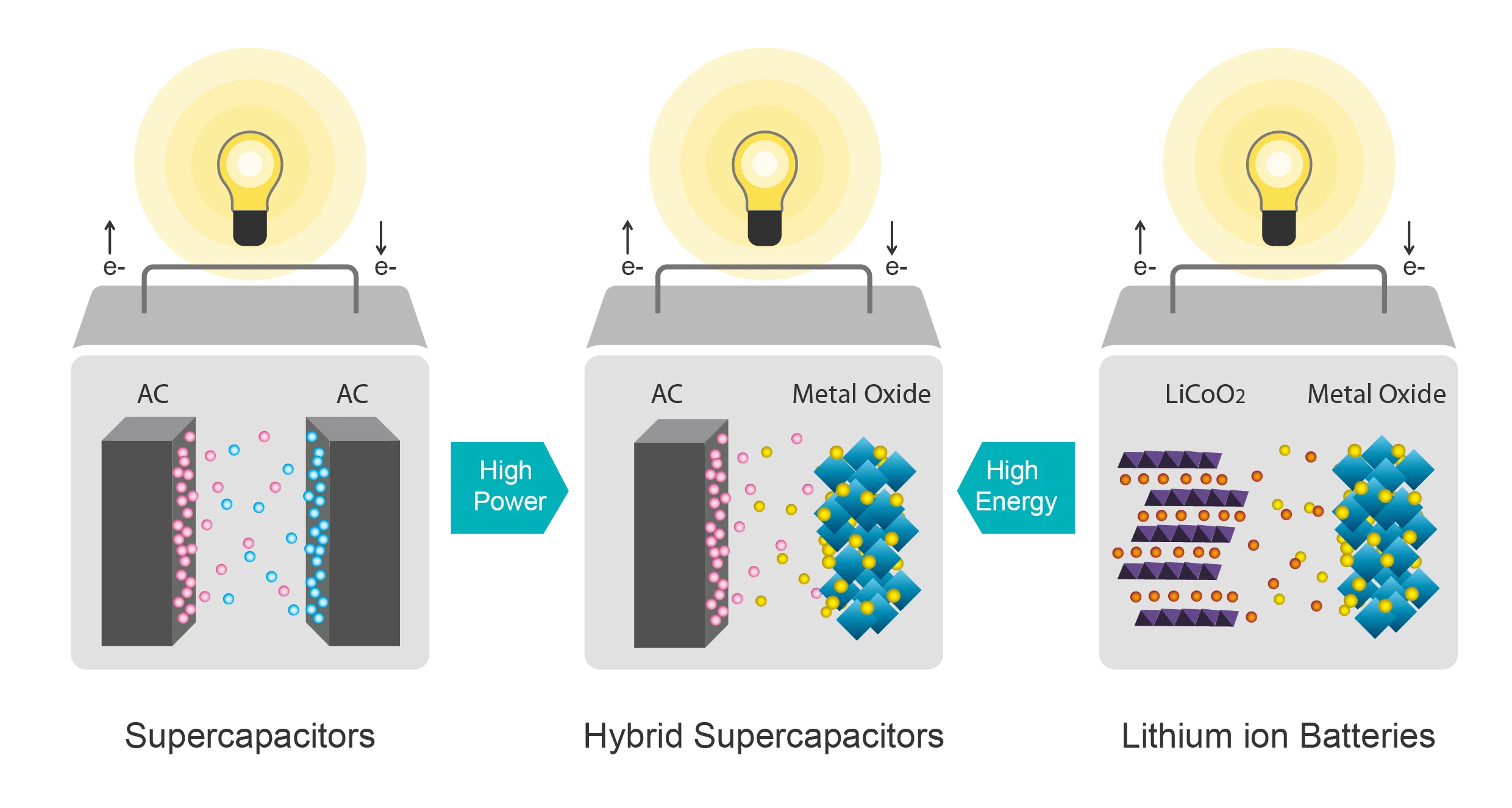

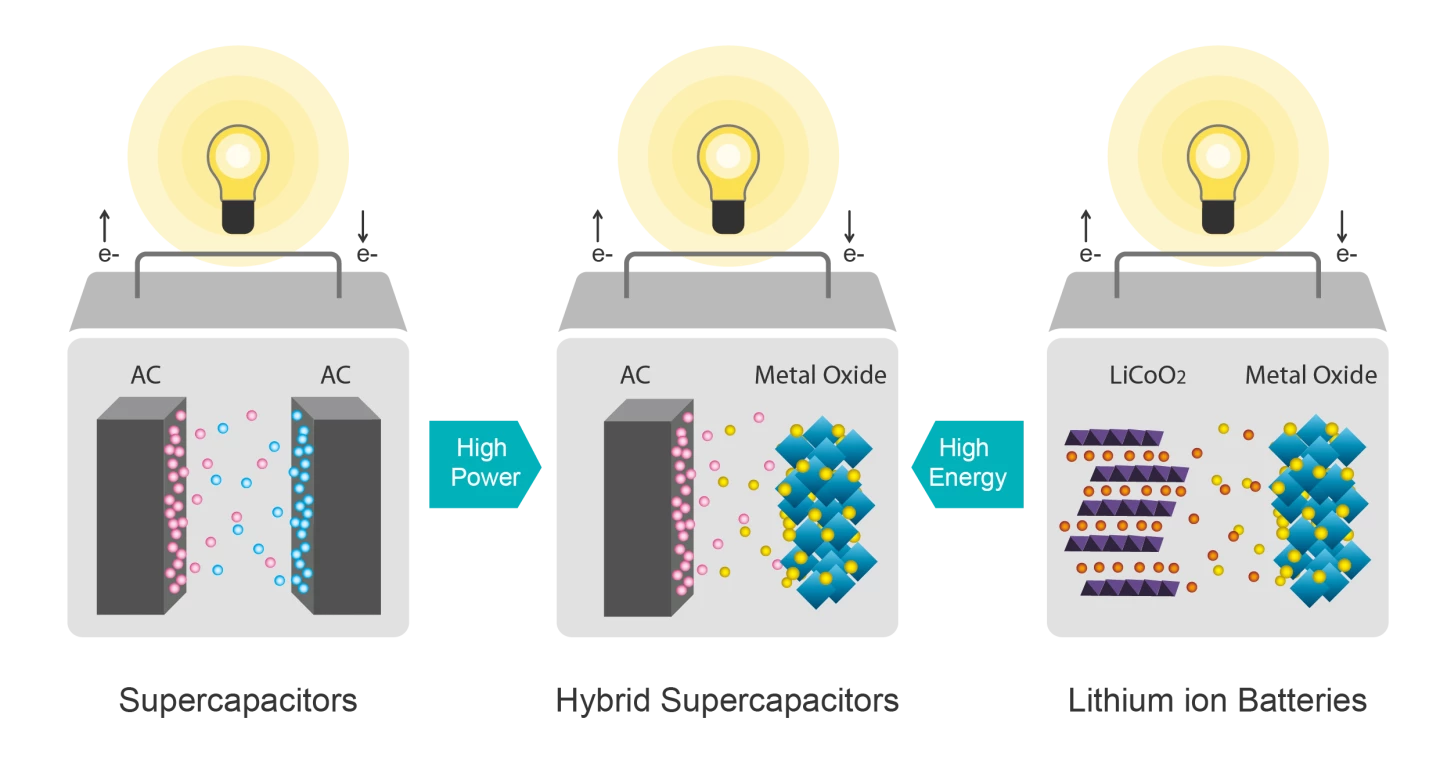

So how do they work? Well, the power capacitor cells are an odd design sitting halfway between a regular carbon-based supercapacitor and a lithium battery cell. Capacitors charge statically, a little like rubbing a balloon on your jumper. That's why they're so good at charging and discharging quickly. Batteries use chemical reactions to store and release charge, which makes them slower, gives them a higher energy density and also their tendency to catch fire and explode due to dendrite formation..

Toomen's powercapacitors have one "activated carbon" electrode made from a variant of graphene, and the other is "based on a lithium compound, but compared with lithium-ion, there's no active lithium in there," according to Verhulst. "There's no chemical reaction; the charges are stored statically, like a supercapacitor. One electrode has some battery effect, but what you don't have is a free flow of lithium ions floating in the battery that can form [potentially dangerous] dendrites." There is some electrolyte involved, but it's really just there as a filler that allows the charges to move. It gets soaked up by the nano-carbon electrode material, so if the cells are ruptured, "very little or none will leak out."

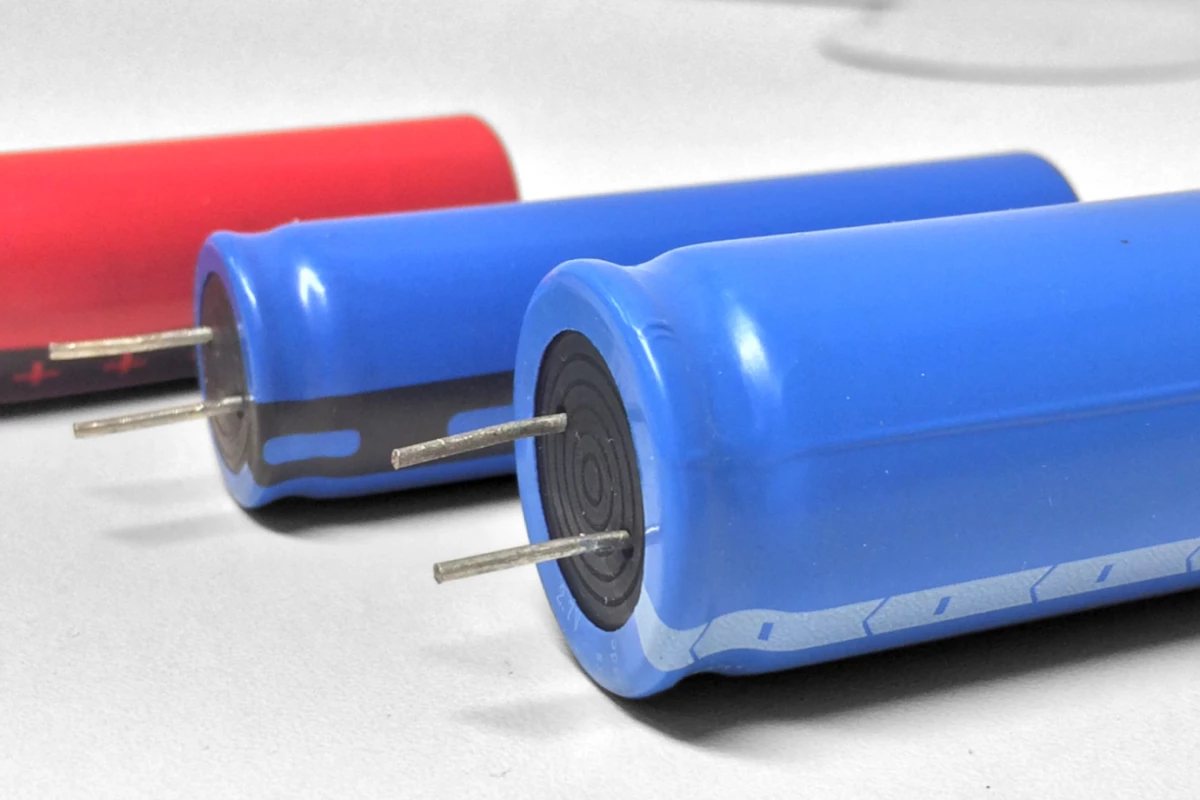

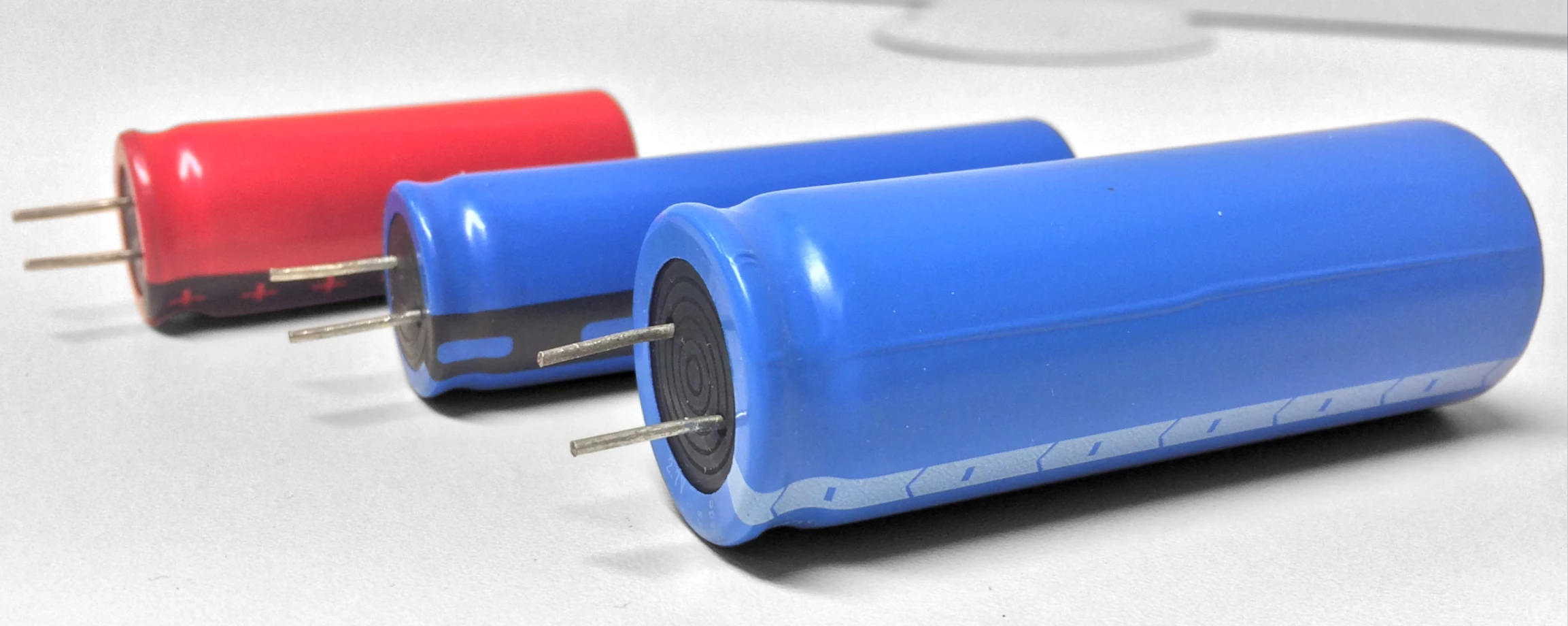

There are currently two variants, one that prioritizes energy density and the other delivering maximum power rates. The high density cells are currently offering between 200-260 Wh/kg, with rated power densities around 300-500 W/kg. The high power cells are getting 80-100 Wh/kg, with power densities around 1,500 W/kg, peaking at up to 5,000 W/kg.

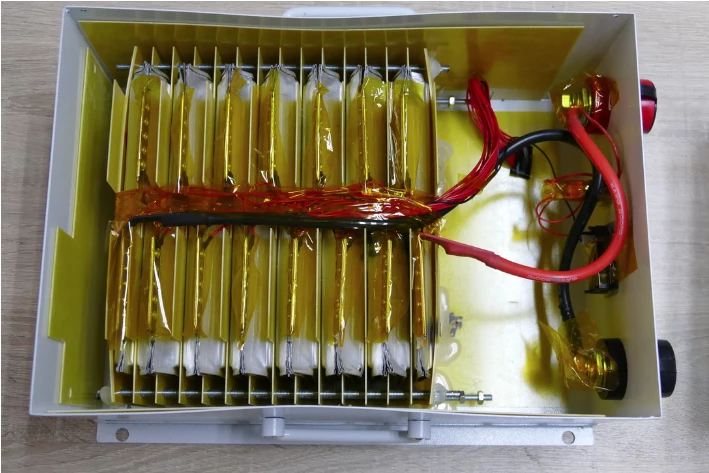

"We also have a prototype pouch cell," says Verhulst, "which has a very interesting volumetric density [more than twice the volumetric density of the highest density cylindrical cells at up to 973 Wh/liter]. But we need more tests to verify that it's really working and safe, because the mechanical stability of pouch cells is more difficult than with cylindrical cells."

To put those numbers in context, a current model commercial ultracapacitor like the DuraBlue from Maxwell offers a much, much lower energy density of just 8-10 Wh/kg but a sky-high power density around 12,000-14,000 W/kg. A good lithium battery, on the other hand, typically offers 150-250 Wh/kg and power-wise is somewhere around the 250-350 W/kg area. So while it's clearly a trade-off between power and energy storage, the Toomen power capacitors certainly offer power advantages at the high density end of the scale, and huge density advantages at the high-power end of the scale.

This isn't the end point, either. "I'm in communication with the Toomen team every day – even now that they're all basically under house arrest with the coronavirus quarantine," says Verhulst. "The founder is a bit older now, but he has 200 patents under his name. They come from the energy industry, but they're clearly very good in chemistry. They've tested hundreds of variations combining a supercapacitor with carbon and one lithium electrode like you'd find in a lithium battery, and I can see through the test reports they've had a gradual improvement in performance. I'm pretty sure we can push it even further."

Verhulst says the high-power cells are already in production, and his company Altreonic - Kurt.Energy is already making sales into the automotive, energy storage and solar markets, with the key driver being the Toomen cells' ability to work flawlessly across such a wide range of temperatures. He's working on drawing the investment needed to get the high-density cells into serious volume production, and meanwhile a team at a Munich University is evaluating the power capacitors for a possible role in deep space, where temperatures can reach -200 ºC (-328 ºF).

Theoretically, these power capacitors could be wrapped up into a big battery pack and used to power a long-range, super fast charging EV. The high-power versions can charge to 75 percent in five minutes, for example. But Verhulst doesn't believe this tech will flood the automotive market. "You need a charger that can handle it," he tells us. "A 10 kWh pack charged in five minutes means you'd need a 100 kW charger. If you then go to the big ones, say a 100 kWh battery, you'd need a megawatt charger. That's a lot. That's a whole power station. So scalability is still an issue.

"I'm an engineer, I'm being pragmatic. It's still too early for everyone to go full electric. We need something better. It's working now if you drive locally, say you do 50-80 km a day and you plug in at home. That works today. For longer distances, if you want to be practical, hybrids will do the job. But the point is that if you use a hybrid, you can have a fuel consumption maybe 90 percent lower. That's significant, but for whatever reason, people seem to be either 100 percent for electric, or 100 percent for conventional cars. I think the practical solution for the next 10-20 years is hybrids."

With that in mind, the power capacitors offer plenty of immediate utility in the world of hybrid power systems, where you can use an extra high density power source like gasoline or hydrogen to deliver sustained power, and a power capacitor with a smaller capacity as your high-power buffer, able to put out big power immediately and accept high charge rates when necessary.

Some Kurt.Energy clients, for example, are building big ol' flow batteries for energy storage. They're big and cheap and store plenty of energy, but they don't have much of a power output. "By making, say, a third of your capacity a power capacitor system," says Verhulst, "you get yourself a system that can be responsive to dynamic loads."

As for the price? Verhulst says it's a difficult question. "We are clearly more expensive today, because there's no volume production. On the other hand, if you take into account that you typically need no BMS or cooling system, and other factors like safety and lifetime, well, if you look at say the dollars per kilowatt per cycle, then we're cheaper. This is something you should only buy if you want to use it for 10 years, at this point." Apart from the high price of graphene, though, he says there's no reason why mass production couldn't bring prices much closer. "For the moment," he says, "it's mainly economies of scale."

Not to mention, the lack of battery management and cooling systems could indeed significantly boost the energy density of a power capacitor system at the full pack or vehicle scale, simply because you don't need to carry the weight and size of those components. So the full potential of this system seems yet to be unlocked. We'll keep an eye on this space!

Source: Kurt.Energy