It's an unfortunate fact that many "cold chain" items such as food or medicine are shipped in single-use expanded polystyrene foam (EPS) packaging, which is non-biodegradable and difficult to recycle. Such is not the case with a new material, however, which is made from discarded paper.

Developed by scientists at the Dresden University of Technology, the EPS-alternative insulating medium is currently in the process of being commercialized by German company easy2cool.

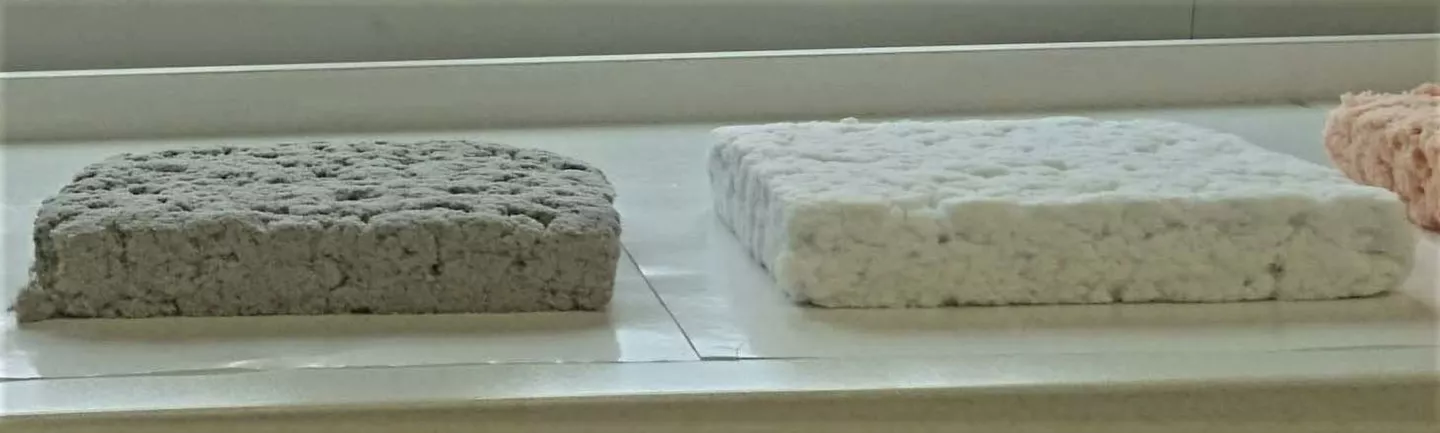

Although the exact production process is a trade secret, it does involve first converting shredded paper waste into a slurry, then utilizing a special process to dry slabs of that slurry into mats of a cellulose-fiber material. The low density and narrow pore size of that material is claimed to give it an EPS-like low thermal conductivity, allowing it to act as a highly effective form of insulation.

Unlike EPS, however, the material can be fully recycled at existing facilities – plus it will biodegrade in landfills. Additionally, instead of requiring petroleum-based raw materials, the mats utilize waste that might otherwise be dumped or burned.

It should be noted that the mats currently incorporate a waterproof outer plastic film wrap, that has to be separated from the underlying insulating material for recycling. That said, the manufacturers are working on more sustainable alternatives, such as a cellulose-based external barrier layer that could be directly applied to the material.

Source: TU Dresden