If there's one thing that needs to be aerodynamic, it's an airplane wing. Conventional wing designs however, suffer from a glaring weakness in this respect: the joint where the main wing meets the trailing flaps. Michigan-based FlexSys has developed a way to optimize wing aerodynamics with FlexFoil, a seamless variable geometry airfoil system that could deliver fuel savings of up to 12 percent.

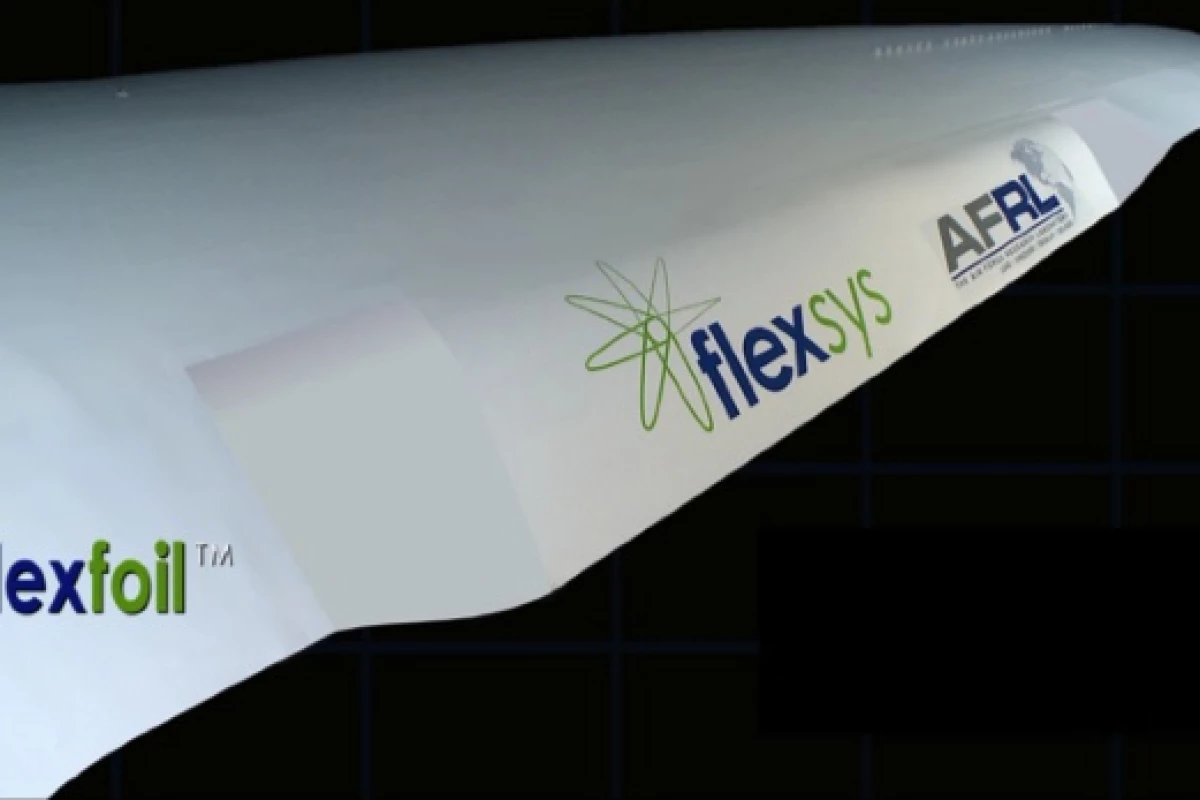

In development since 2001, FlexFoil is made from what is described only as "aerospace materials," and is seamlessly integrated into the trailing edge of the wing. It can be retrofitted into existing wings, or incorporated within new ones.

Based on a technology known as "distributed compliance," the morphing structure integrates actuators and sensors that, according to Flexys, results in "large deformations in shape morphing with very small strains."

According to a 2006 paper co-written by the inventor of the system, mechanical engineer Dr. Sridhar Kota, the foils are "optimized to resist deflection under significant external aerodynamic loading and are just as stiff and strong as a conventional flap."

More precisely, they can reportedly tolerate "well over" 10,000 lb (4,536 kg) in air loads. Additionally, the design is said to distribute pressure more evenly throughout the wing, resulting in less strain in any one area.

When retrofitted onto a wing, FlexFoil can reduce fuel consumption by a claimed 4 to 8 percent, with that number climbing to 12 percent for "clean sheet" builds. The system is also said to reduce wind noise by up to 40 percent on landing, and to lessen build-up of both ice and debris.

What's more, the technology could be applied to anything that moves relative to a fluid medium – that could include things like helicopter rotor blades, wind turbine blades, boat rudders, or pump impellers.

FlexFoil was officially introduced to the public this week at the AIAA (American Institute of Aeronautics and Astronautics) SciTech exposition in Washington, DC. Plans call for flight tests to be performed this July at NASA's Dryden Flight Research Center, where the flaps of a Gulfstream business jet will be replaced with the foils.

A prototype foil can be seen morphing in the video below.

Source: FlexSys