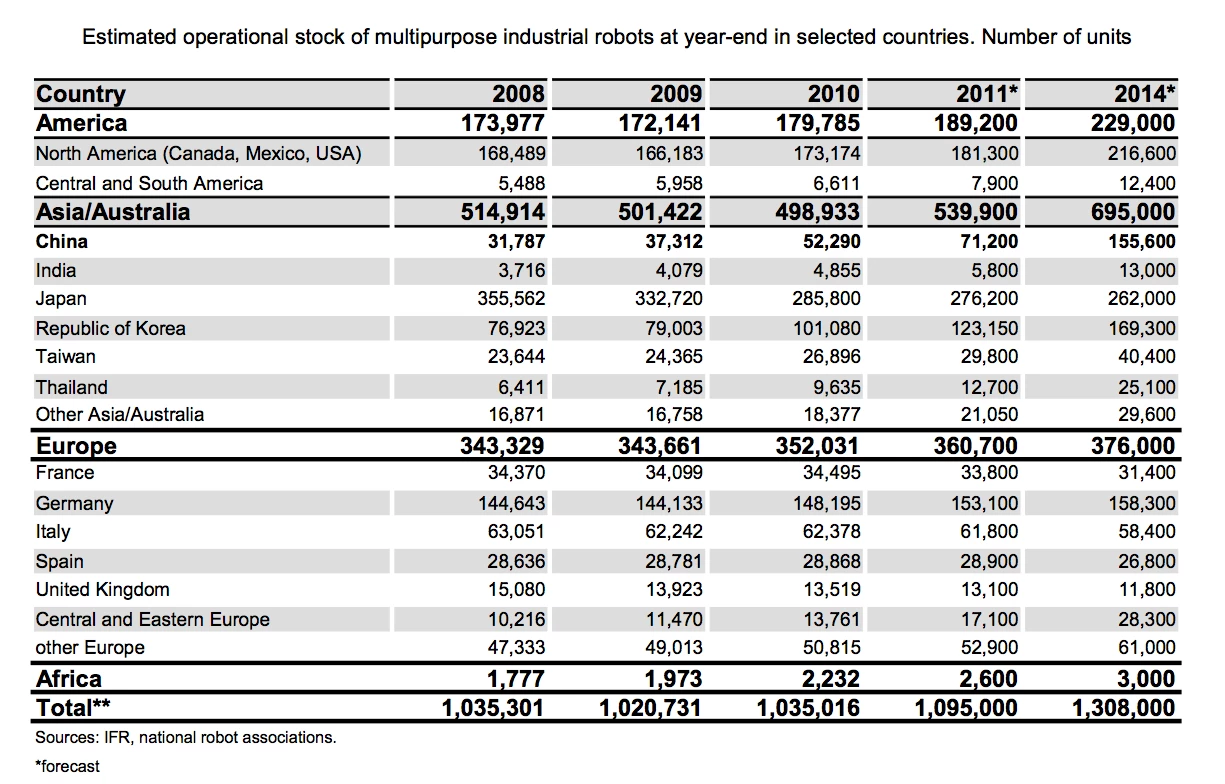

The world's industrial robotics industry will get considerably larger in the near future as Taiwan-registered Hon Hai Precision Industry Co (best known as Foxconn) has announced plans to begin building industrial robots. Its initial plans of building one million industrial robots for its own purposes will nearly double the number of industrial robots in the world (currently The International Federation of Robotics puts that number at 1,095,000). Foxconn is best known as the largest exporter in China, the assembler/manufacturer of Apple's iPad and iPhone and for the extraordinarily high suicide rate of its employees.

Hon Nai is planning to invest heavily in the robotics area, with US$223 million for a new Research and Development facility and more for a robot manufacturing plant. The company is expecting to gross NT$120 billion (US$4 billion) from robot sales over the next 3-5 years and it has the additional benefit of its own diverse manufacturing facilities becoming its first and biggest customer.

Industry analyst and the publisher of the Robot Report, Frank Tobe, told Gizmag that Foxconn's move has massive ramifications for the robotics industry, which has previously been dominated by Japan and Germany.

"It's a painful wakeup call to ABB, KUKA and Fanuc that their products are not flexible and easily trainable enough to be useful to Foxconn or any other new-tech electronics assembler and sub-components manufacturer even though the electronics business is a big client of those very same robot manufacturers", said Tobe.

"Things are changing from robots having a small library of moves, where they precisely and reliably repeat those moves 24/7. New tech is more personalized and manufacturing is following with small quantities of thousands of variants of base products. Industrial robots now need to keep up with those changes, and at present they have not, hence, Foxconn's intent to build robots that will," said Tobe.

"Some are skeptical that what they are planning isn't really to build robots but rather automation machinery. My sources are saying the opposite - Foxconn is planning on entering the robot manufacturing business with a variety of flexible, easily trainable and low-cost assembly-line robots."

The project is expected to create around 2,000 jobs in Taiwan, and initial indications from other news sources that the million industrial robots would replace the jobs of half a million Chinese workers have now been clarified.

The robots are intended to assist in overcoming Foxconn's well-documented workforce problems, not by replacing those workers with robots, but by supplementing those workers.

Hon Hai Chairman Terry Gou said that the company intends to maintain its workforce and train existing workers for more important tasks. Gou founded Hon Hai in 1974 and now produces consumer electronics products for the likes of Apple, Acer, Amazon, Intel, Cisco, Hewlett-Packard, Dell, Nintendo, Nokia, Microsoft, Motorola and Sony Ericsson.

Foxconn has had a lot of trouble hiring, training and maintaining a workforce capable of such massive output and the industrial robots will enable the company to reduce its hiring frenzy while improving output and workforce morale.

Foxconn has 13 factories in China (including the massive industrial complex referred to as "Foxconn City" in Shenzen, plus manufacturing facilities in India, Mexico, Brazil, Slovakia, Poland and the Czech Republic, where it is the country's second largest exporter.

A letter of intent with the local Taiwanese Government was signed last week signifying the company's intention to build an intelligent robotics and automation equipment manufacturing hub in Taiwan under the name of Hon Hai subsidiary, Foxnum Technology.

The current size of the industrial robotics market puts Foxconn's investment and intent to build a million industrial robots for its own use in perspective.

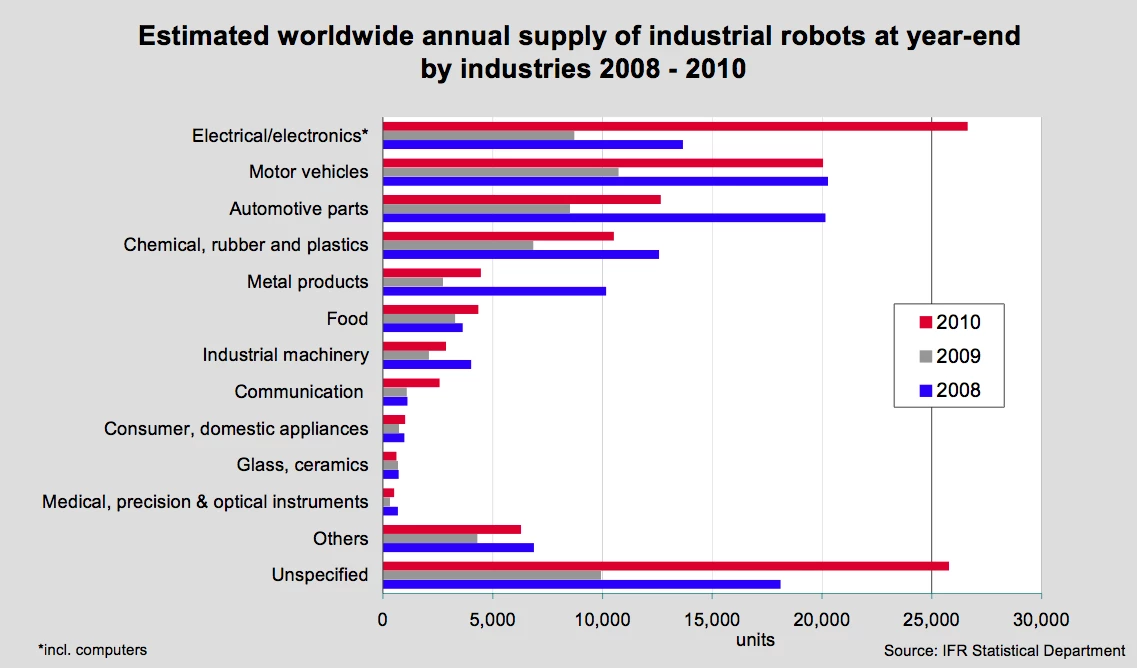

In 2011 around 140,000 industrial robots will be sold globally, an increase of 18% on 2010, and the largest number ever, after the global financial uncertainty of 2009 saw just 60,000 units sold, the lowest number for 15 years. The automotive and electronics industries were the main drivers of the strong recovery.

In 2010, industrial robot sales were valued by the IFR at US$ 5.7 billion. It should be noted that the figures cited above generally do not include the cost of software, peripherals and systems engineering. Including the mentioned costs might result in the actual robotic systems market value to be about three times as high. The worldwide market value for robot systems in 2010 is hence estimated by IFR to be US$17.5 billion.

Interestingly, the massive growth of industrial robots being deployed over the next few years will undoubtedly put China at the top of the automation industry.