Ordinarily, when interior walls become wet due to leaky roofs, burst pipes or flooding, fans or radiant heaters are used to dry them. The new FastDry module, however, is claimed to offer a significantly more energy-efficient alternative.

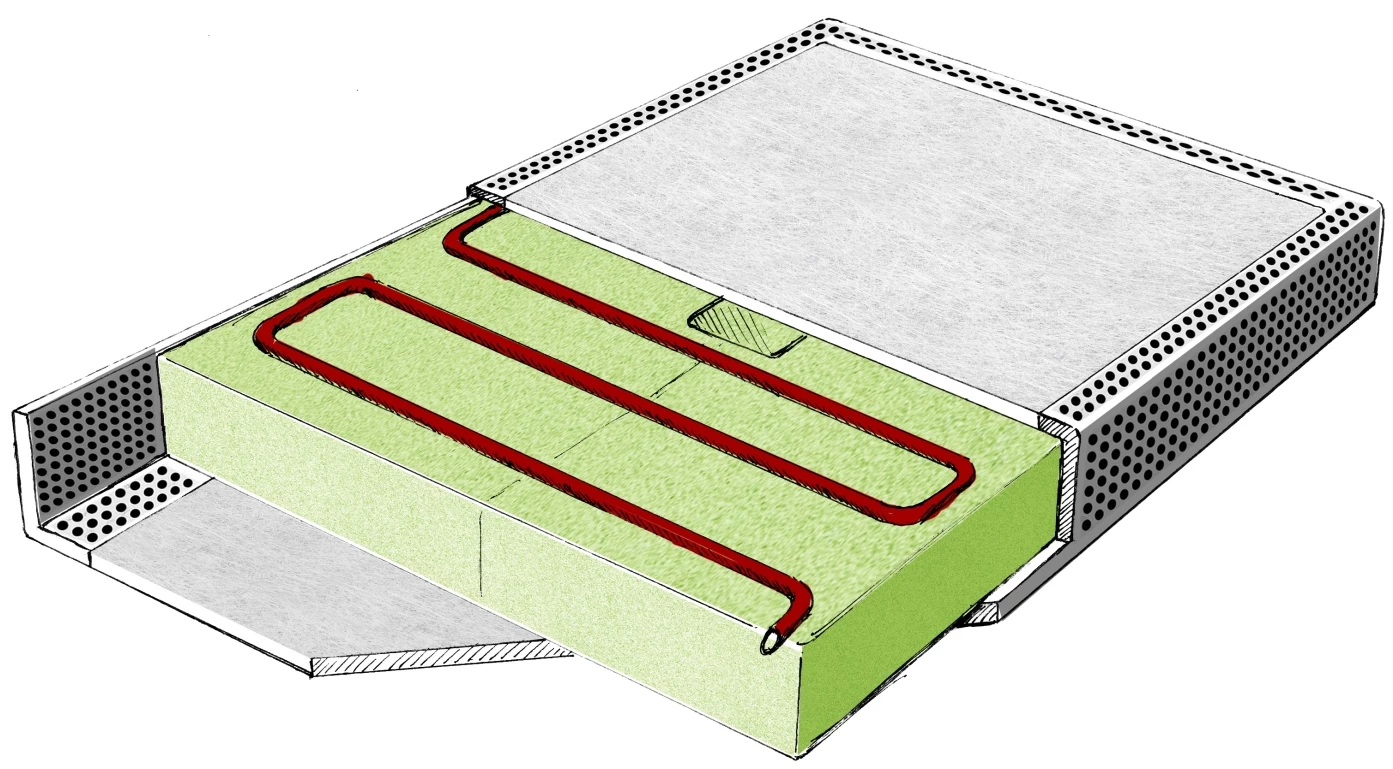

Created by Germany's Fraunhofer Institute for Building Physics, the device takes the form of a rectangular panel that is placed directly against the wet wall in question. Sandwiched between the two screened sides of the panel is a slab of non-flammable mineral fiber insulation – a heating wire runs through the middle of that slab.

As the panel heats the wall, liquid water within the wall material turns to vapor that dissipates out of the wall, through the permeable mineral fibers, and out into the room. At the same time, the insulation helps hold the heat in the wall, minimizing the amount of additional heat that has to be continuously produced by the system.

The FastDry module heats the wall to about 55 ºC (131 ºF), and continuously monitors both the surface temperature of the wall and the amount of power being consumed. It is therefore able to monitor the dampness of the wall, since the drier the wall material becomes, the less the amount of power will be used to heat it to the target temperature. This means the module can be turned off and removed from the wall as soon as it indicates that the wall is dry, as opposed to being left running unnecessarily.

According to Fraunhofer, the technology requires only about 15 percent of the energy needed by standard infrared heating plates to do the same job. Additionally, unlike the heavy-duty fans that are often used to dry walls, it operates silently.

A flexible version of the FastDry module is now also in the works, which could be wrapped around architectural features such as columns or wooden beams.

Source: Fraunhofer