We've heard how 3D-printed concrete buildings can be constructed quickly and easily, but could there be an even faster and simpler method? According to American inventor Alex Bell, there most certainly is – and it involves inflating buildings, then pumping concrete into them.

When we last heard from Bell, he had created a quirky front-wheel-drive bike with under-the-seat steering, known as the Bellcycle.

His new construction technique, called Inflatable Flexible Factory Formwork (IFFF), has been commercialized via his New York City-based startup, Automatic Construction. Here's a quick explanation of how it works …

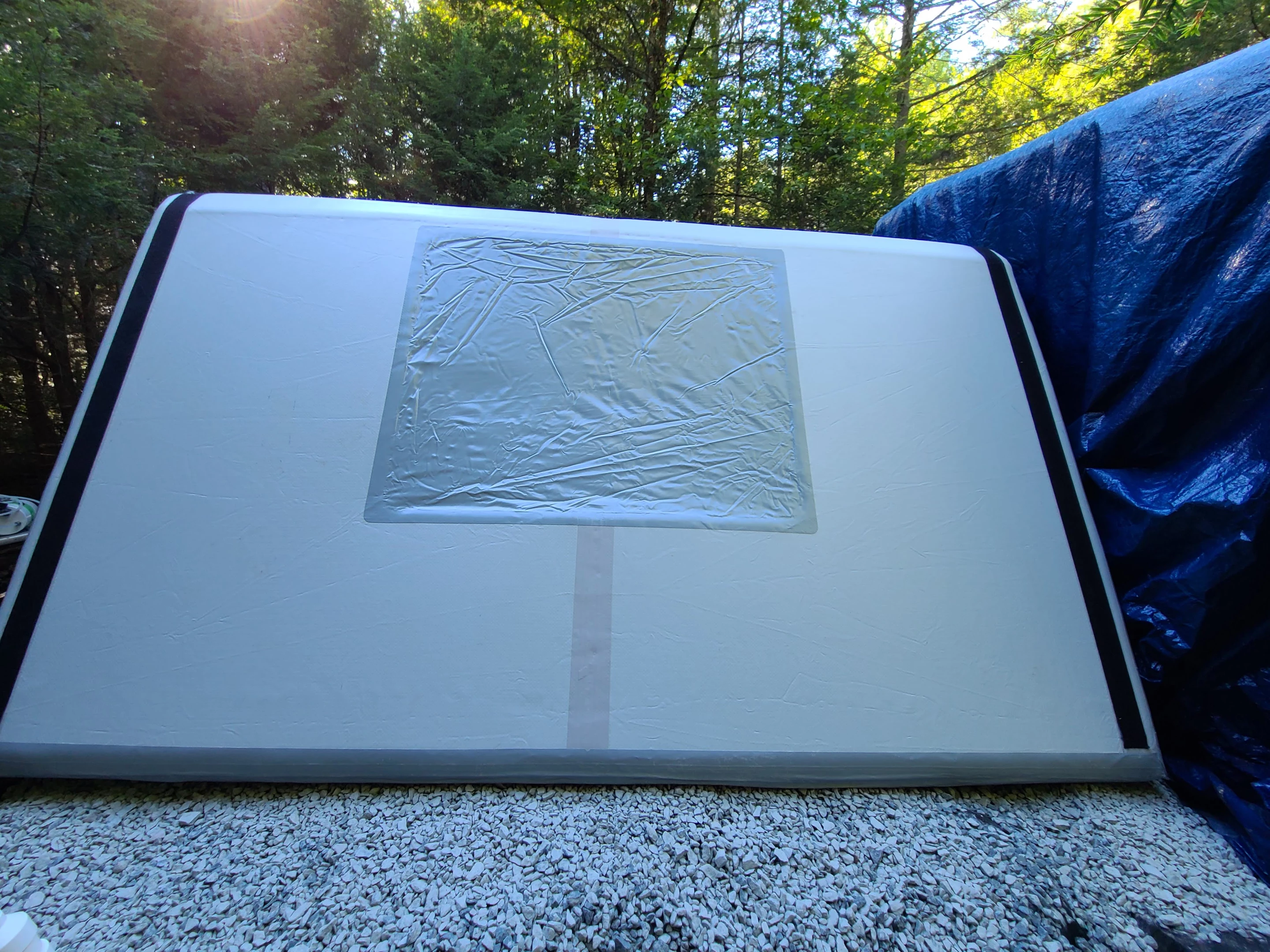

The process begins with a truck delivering a rolled-up PVC (polyvinyl chloride) fabric "form" to the construction site. That flexible form is not unlike a giant version of a rolled up, deflated camping mattress.

After the form has been laid in place, air pumps are used to inflate its walls and roof. This causes it to pop up, taking on the three-dimensional shape of the finished structure. Next, locally sourced wet concrete is pumped into the walls and roof of the form, displacing the air inside.

Once that concrete has set, the result is a solid concrete building shell. The form is not removed from that shell, since it now serves as a waterproof, airtight, and thus energy-saving barrier. Features such as doors, windows, interior drywall and exterior siding are then added.

In the prototype structures created so far, rebar reinforcements have also been added onsite. However, Bell tells us that he ultimately hopes to have the rebar, tension cables and other reinforcing elements preinstalled within the forms.

But just how quickly do the buildings go up?

"For our 100 square foot [9.3 sq m] and 200 square foot [18.6 sq m] prototypes, the inflation took seven to 10 minutes with air," he said. "Then the concrete pump filled them in 1.5 hours. Including labor, our prototypes only cost $20 per square foot. This is significantly cheaper than anything else."

Bell's team is now selling homes direct to customers in New York's Hudson Valley, with one project currently underway and another two signed. He tells us that his company has also signed one contract with a "large commercial contractor" to deliver a structure, and signed another contract to deliver a box culvert to an infrastructure contractor.

Along with homes, commercial buildings and infrastructure-related projects, other envisioned applications of the IFFF technology include swimming pool foundations, rapid-deploy military structures and perhaps even one day skyscrapers, or structures on Mars for use by astronauts.

Source: Automatic Construction