A new type of submersible fish farm could make aquaculture operations much more eco-friendly. The storm-resistant structure is designed to stay out in the deep, cold waters of the open ocean, where it should have less environmental impact than shore-adjacent pens.

While fish farms do help take the pressure off wild stocks, and reduce the need for indiscriminate drift net fishing, they are not without their drawbacks.

First and foremost, when fish are raised in multiple pens located close to the shore, their feces and uneaten food get concentrated in the relatively shallow, warm waters. This waste constitutes a major form of pollution.

Additionally, because space is limited along the coastline, the pens are only as large as they absolutely need to be, potentially leading to overcrowding within them. The stress caused by this overcrowding, combined with the polluted water, can lead to diseases in the farmed fish. What's more, those ailments may spread to the local wild fish.

With such concerns in mind, some groups have developed offshore pens which are larger than traditional pens, and that are located in deep, open water where the fish waste dissipates as it gets carried away by currents. One drawback of such pens, however, is the fact that they may get damaged as they're tossed around in stormy weather – after all, they're not located in protected bays or inlets.

That's where the SeaFisher comes in.

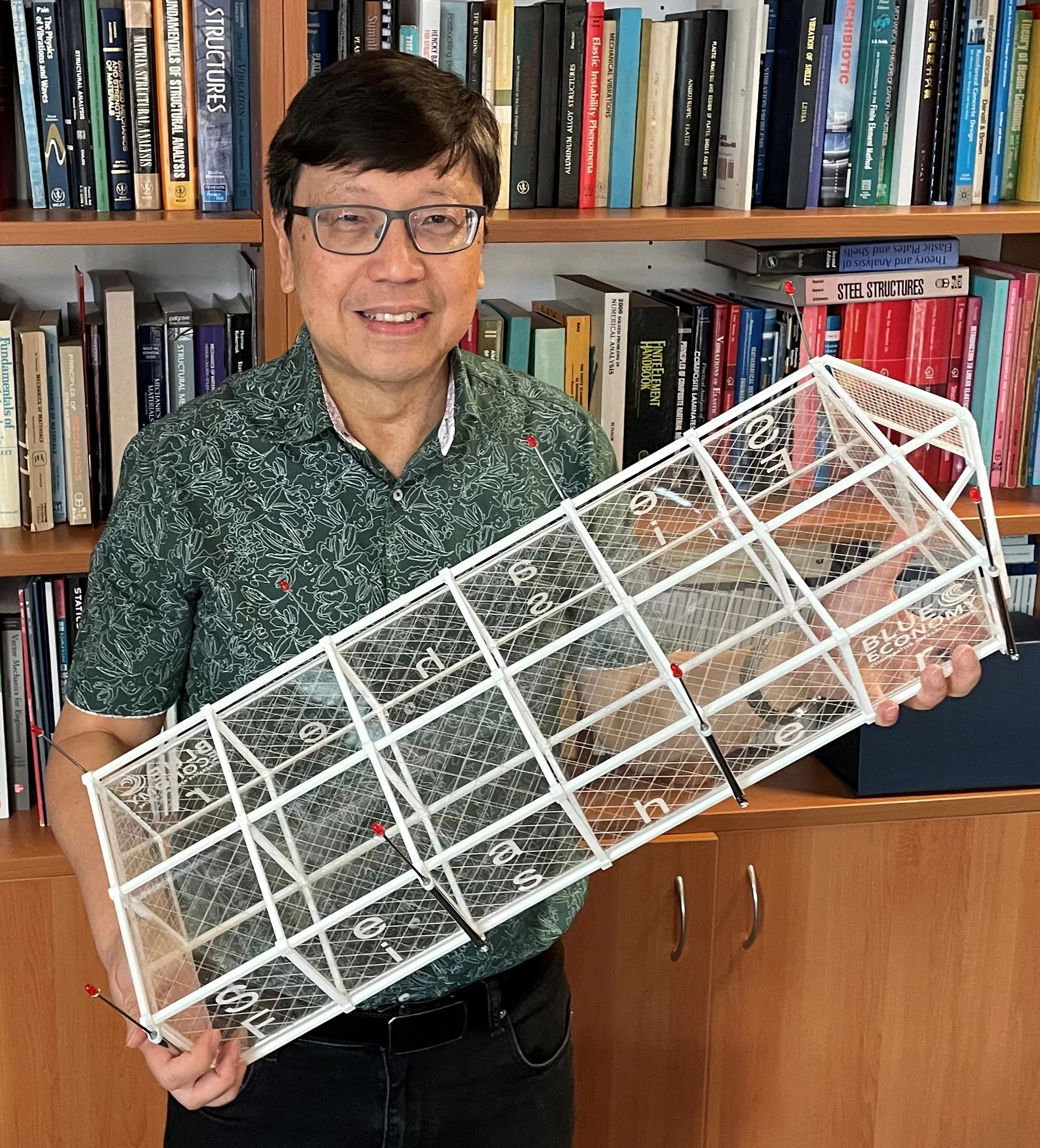

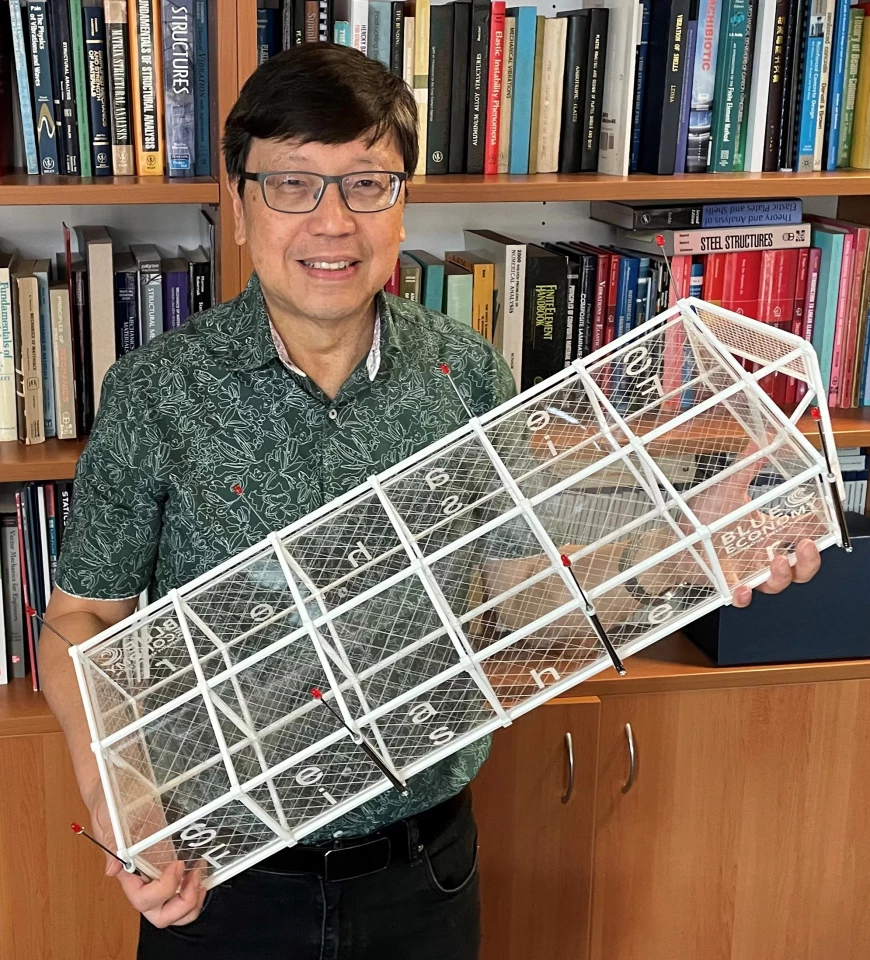

Currently in conceptual form, the structure is being developed by a team led by The University of Queensland's Prof. Chien Ming Wang and Griffith University's Prof. Joerg Baumeister. The project was commissioned by the Blue Economy Cooperative Research Centre, an Australian government-funded nonprofit group.

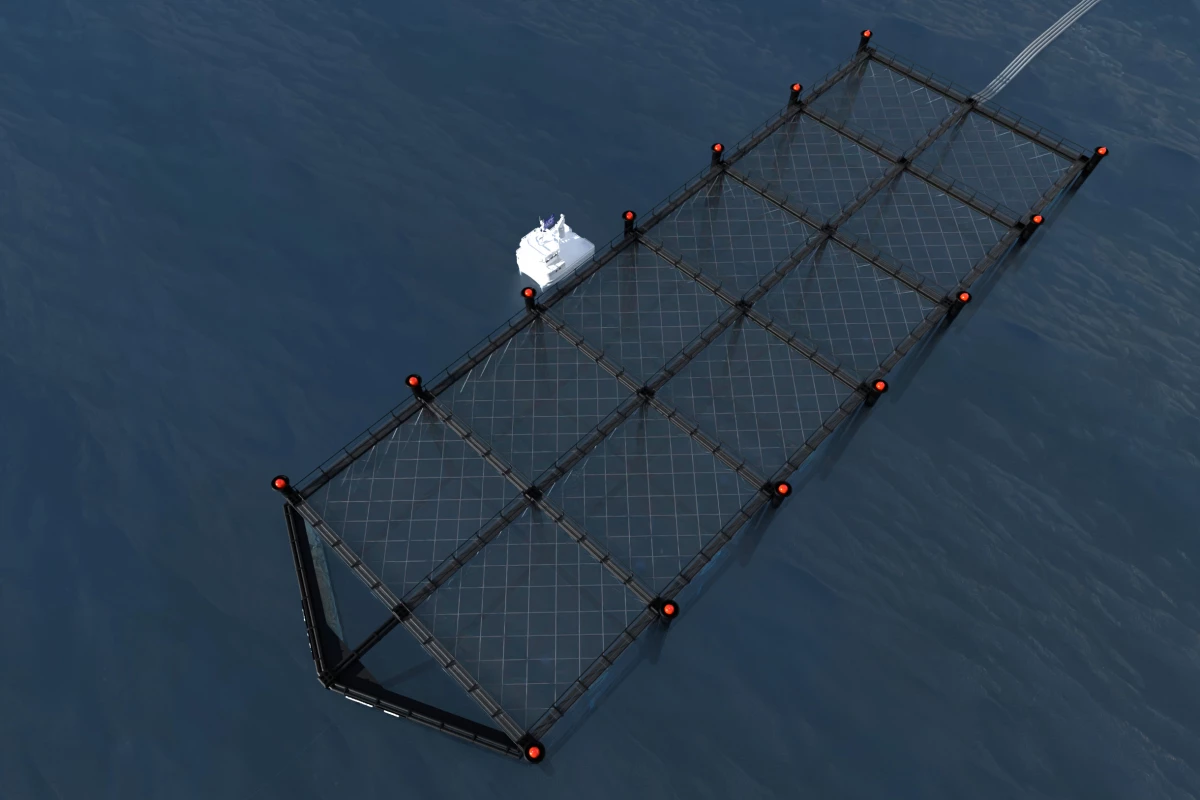

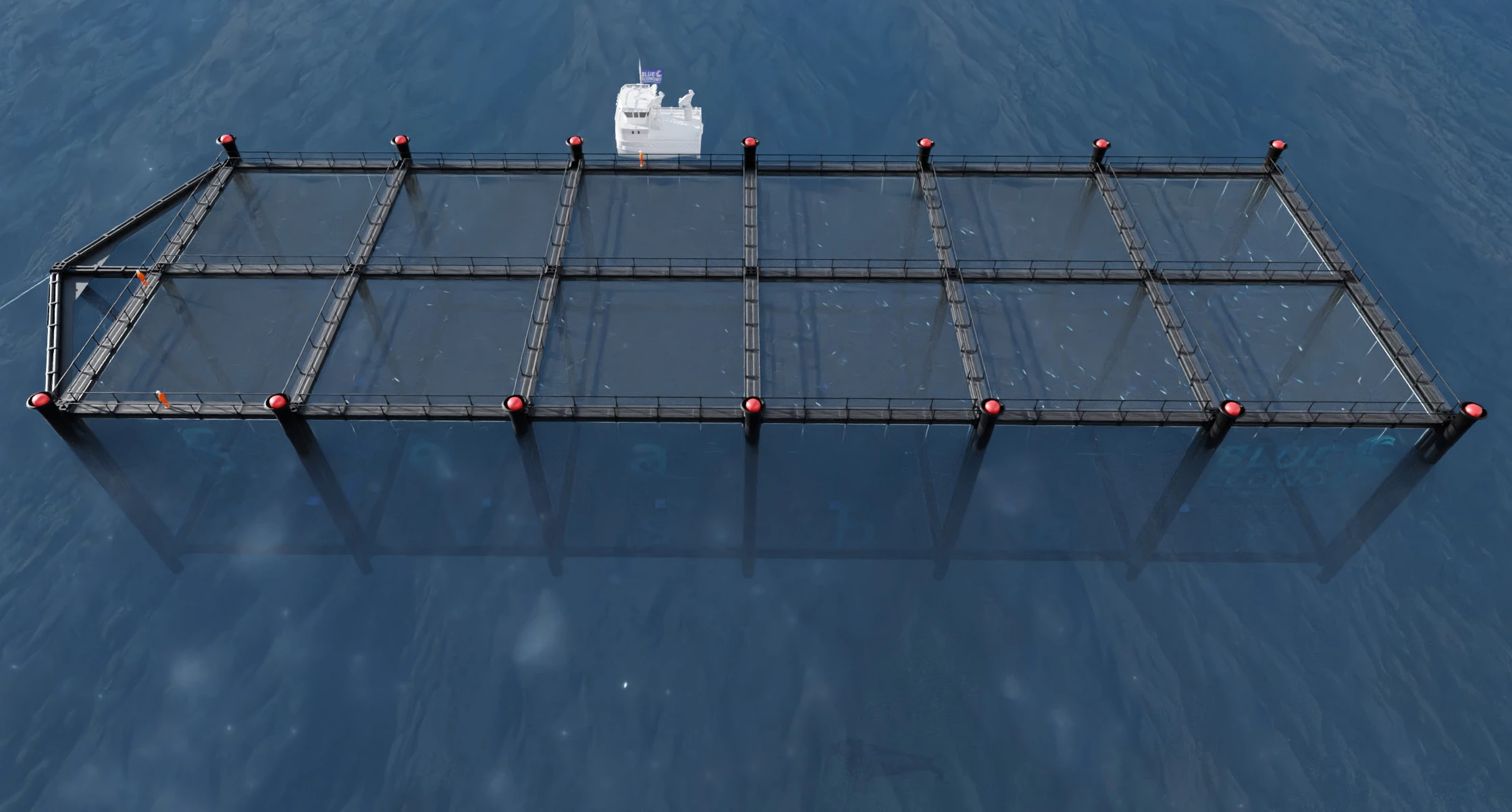

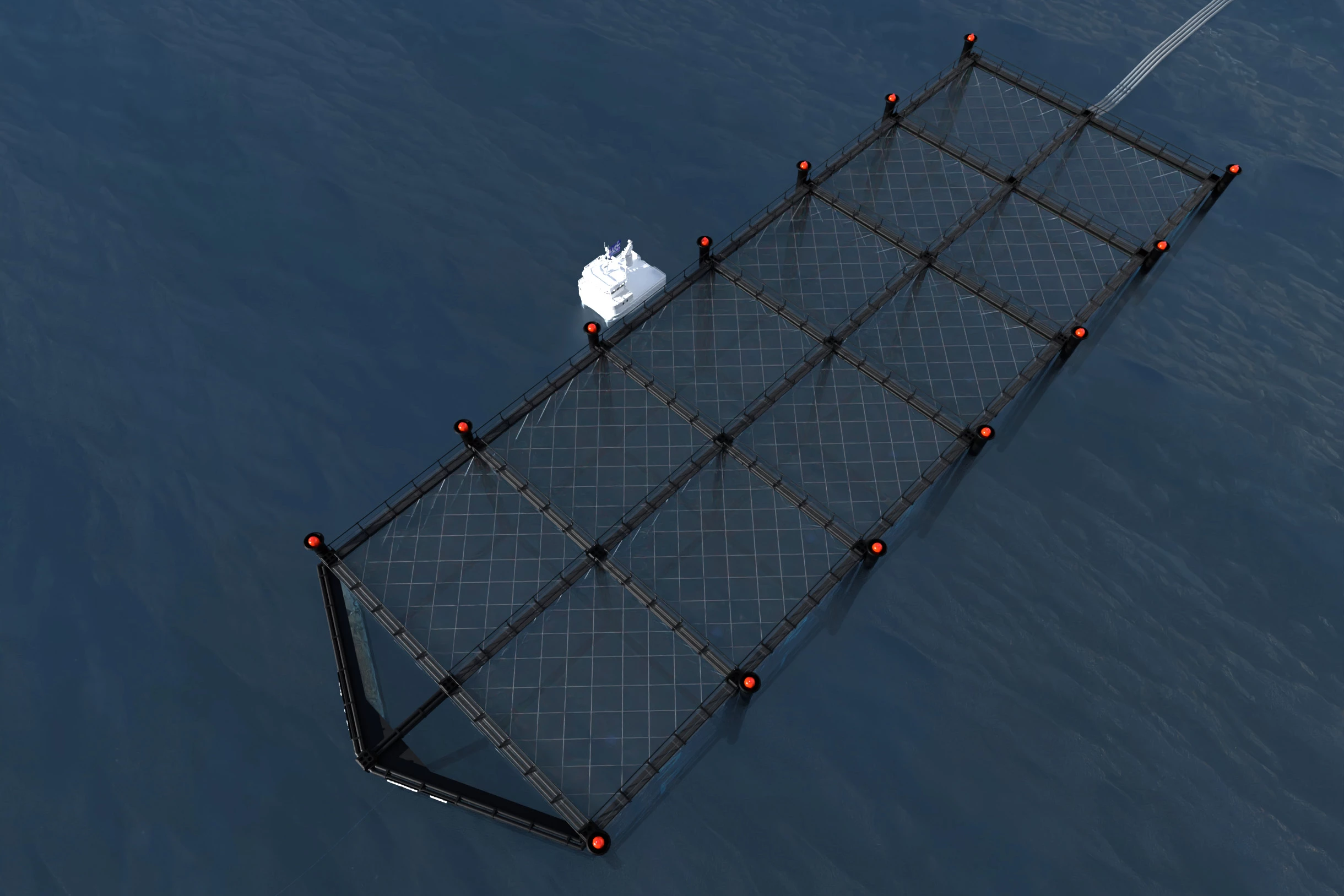

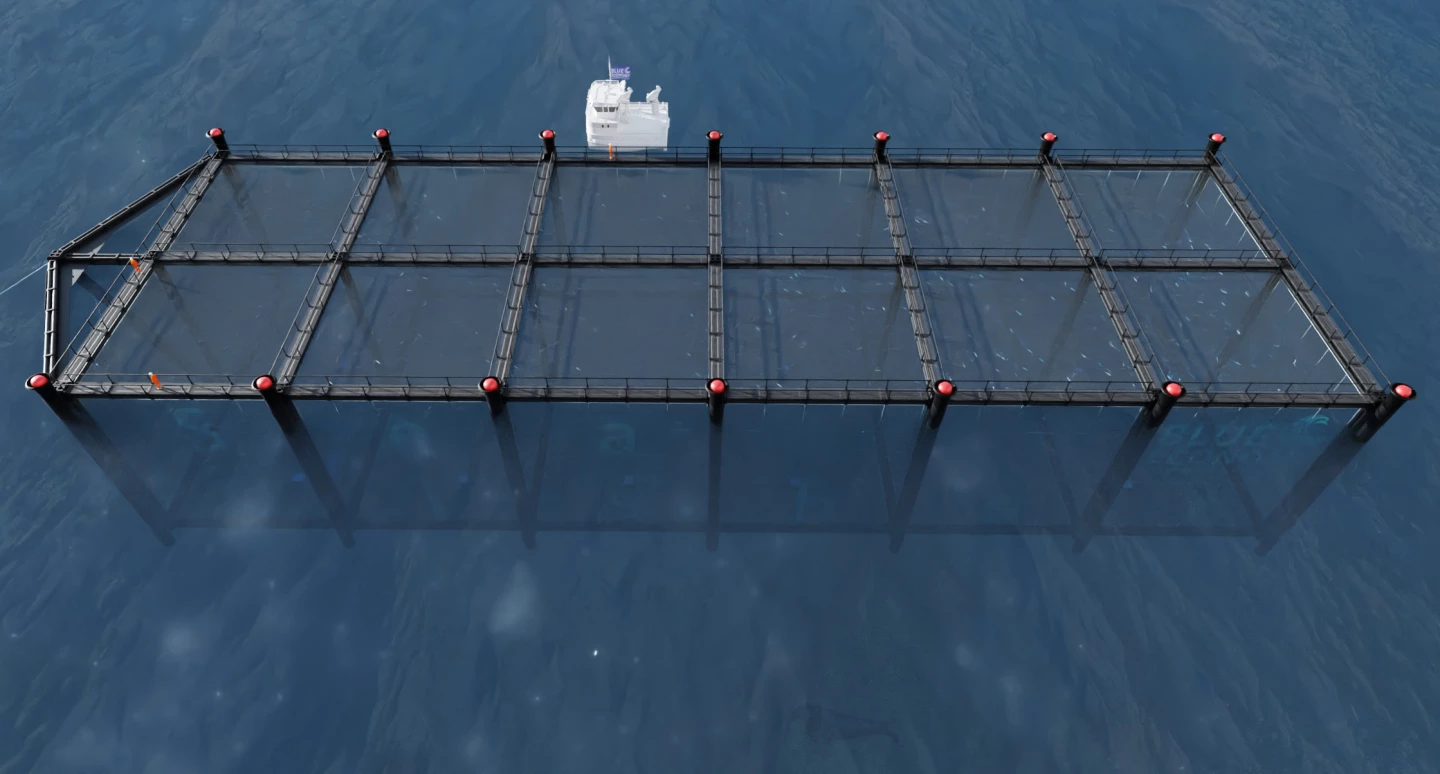

Each SeaFisher measures 120 m (394 ft) in length and incorporates 12 polyester-netted cubical pens arranged in two rows of six. Its frame is made up of lightweight high-density polyethylene pipes linked together by custom connectors.

The whole thing is kept in place by a seafloor suction anchor, which is moored to the front of the structure. This single point of connection to the seabed allows the SeaFisher to continuously pivot relative to the anchor, so that it's always aligned with the direction of the waves. A cowcatcher-like shield in front helps divert floating debris.

As long as the waves aren't too large, the SeaFisher stays floating at the surface. When the weather starts getting rough, though, water gets pumped into the structure's polyethylene pipes. Doing so allows the SeaFisher to sink to a maximum depth of 20 meters (66 ft), where it stays to ride out the storm.

Once the storm has passed, the water is pumped out of the pipes, causing the structure to resurface. And yes, the pens do have netting across their tops, so the fish stay in while the SeaFisher is submerged.

The scientists are now in the process of testing small-scale models, after which construction of full-size prototypes will commence. It is believed that each SeaFisher will ultimately sell for about US$6 million, which is considerably less than most existing offshore fish farms.

And hopefully, the technology should pay for itself in relatively short order.

"We estimate that each cubic cage [of 12 in one SeaFisher] could comfortably house 24,000 fully grown, 5-kilogram [11-lb] finfish," says Prof. Wang. "It could be used to farm different finfish species next to each other and be adapted to grow seaweed, utilizing waste from the fish pens to fertilize the plant crop."

A paper on the project, which also involves researchers from the University of Tasmania, was recently published in the Journal of Marine Science and Engineering. The SeaFisher's features are illustrated in the video below.

Source: The University of Queensland