Whether you're an athlete or someone experiencing foot pain, it's important to eliminate high-pressure areas in the soles of your shoes. An experimental insole could help, by showing where such areas are located during a variety of activities.

Currently, in order to produce a "pressure map" of the soles of a person's feet, a specialist will have them walk barefoot across a pressure-sensitive floor mat in a foot clinic. Custom insoles will then be made for the patient, shaped to relieve pressure in the areas of their feet where it occurs most.

While this system works OK, slowly walking across a short stretch of mat doesn't necessarily reflect what someone does with their feet throughout a typical day. And for athletes, it definitely doesn't provide a full picture of the foot pressure they experience as they're running and jumping.

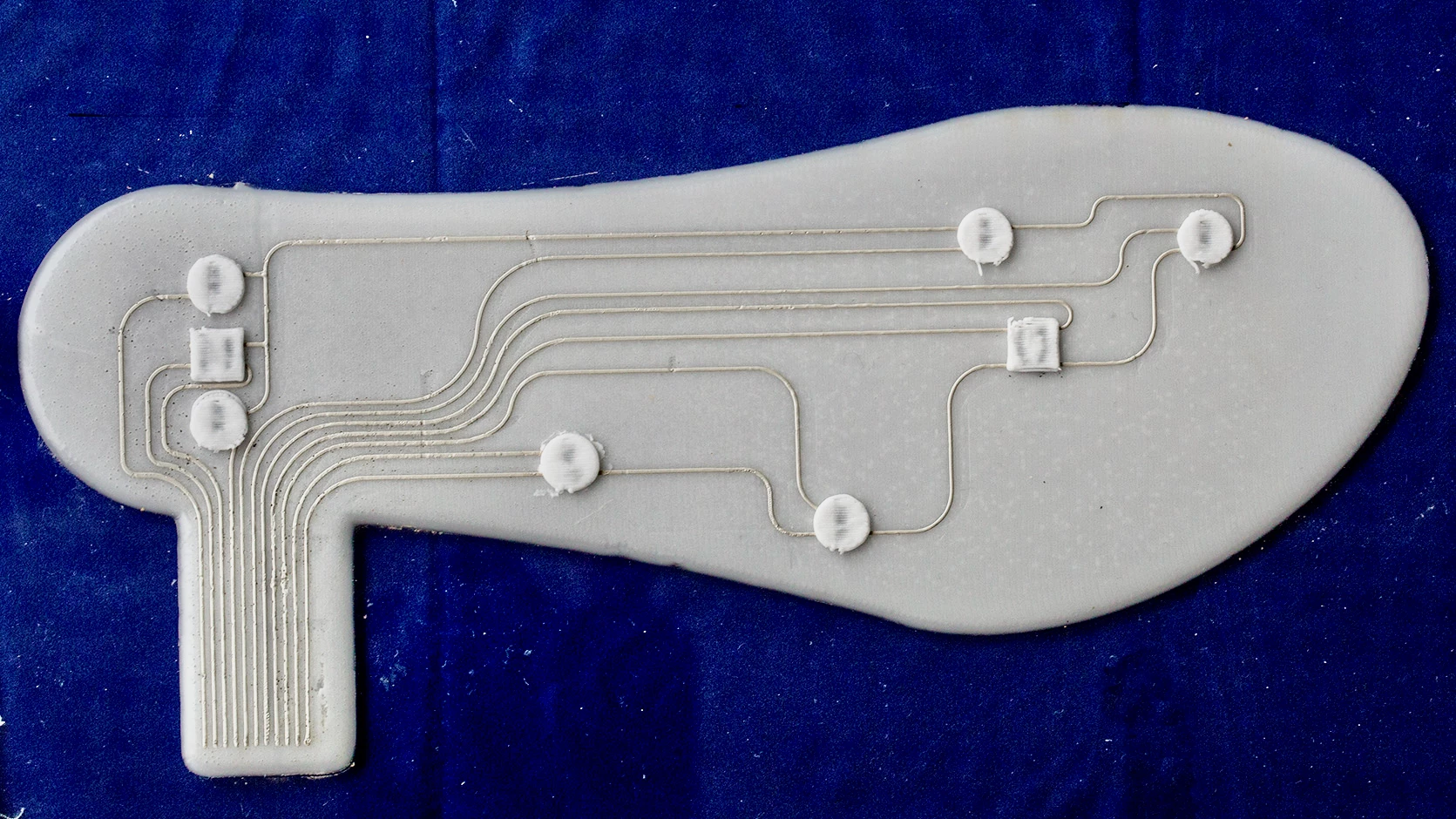

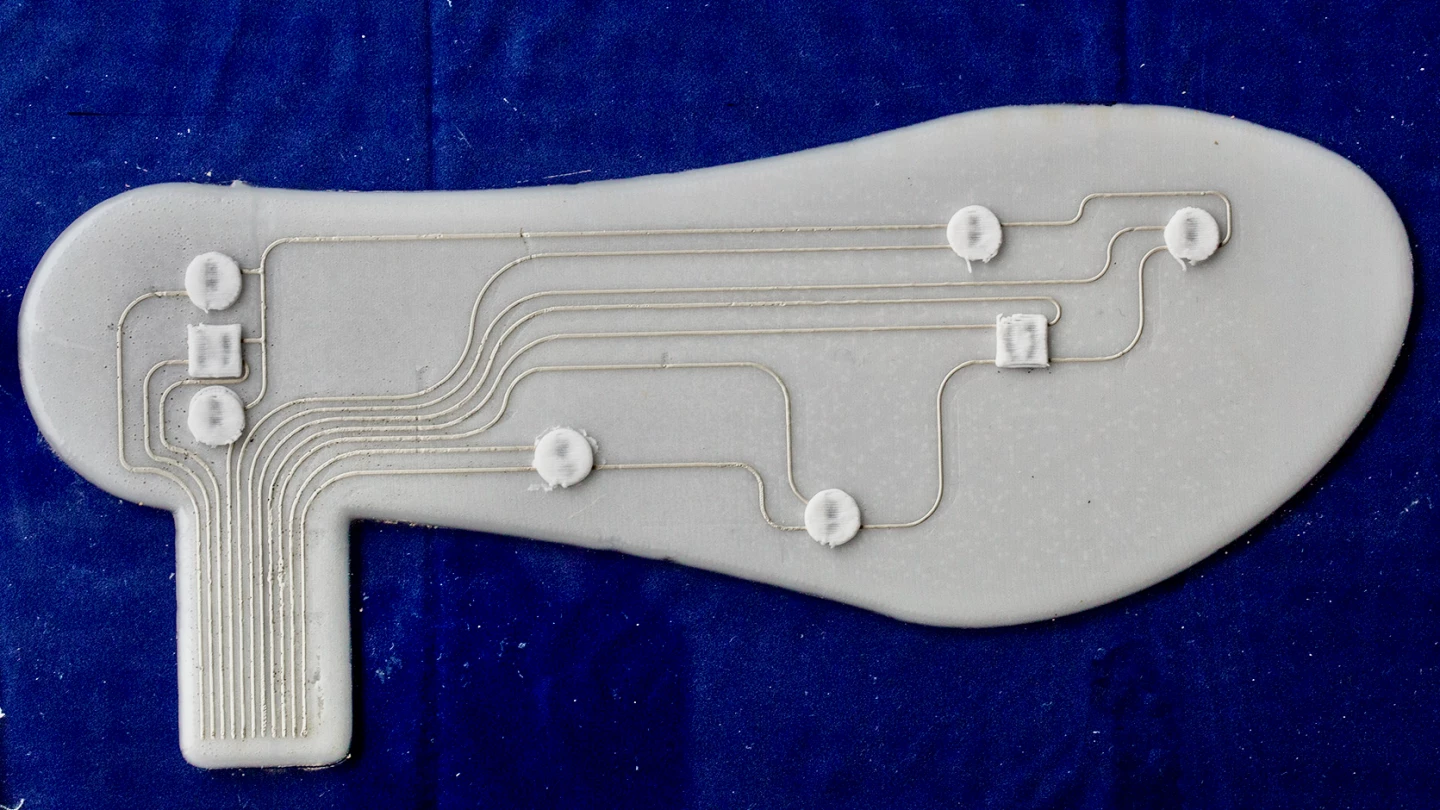

Seeking a better alternative, scientists from Switzerland's ETH Zurich, Empa and EPFL research institutes developed the new insoles. Worn inside an existing pair of shoes, the devices contain multiple piezoelectric sensors, located in areas where pressure typically occurs.

Although the current prototypes are hard-wired to a computer and power source, the idea is that the final wireless version could be worn throughout the day for several days, recording and mapping pressure points. That data could then be used to produce a 3D-printed set of custom permanent insoles.

In fact, the pressure-sensing insoles themselves are 3D-printed. First, a flexible base layer of silicone and cellulose nanoparticles is laid down. Next, a conductive silver ink is used to print the conductors onto that base. A carbon black ink is then used to print the sensors onto the conductors. Finally, another layer of silicone is applied to protect the electronics.

This relatively simple and inexpensive production process is one of the technology's main selling points, as it would allow the insoles to be sold at a much lower price than existing products. And in tests performed so far, the new insoles have performed very well.

"You can tell from the pressure patterns detected whether someone is walking, running, climbing stairs, or even carrying a heavy load on their back – in which case the pressure shifts more to the heel," said Empa and ETH's Gilberto Siqueira, co-leader of the study.

A paper on the research was recently published in the journal Scientific Reports.

Source: Empa