A new partnership between Loughborough University in the UK and garment manufacturer the Yeh Group aims to kick 3D printed fashion into gear. The idea is to cut out the waste of the clothing industry and hopefully arrive at the project's eventual goal, which is to provide a system for personalized, printed polymer clothing that takes just 24 hours to produce.

The clothing industry is huge, withconsumers in the UK alone spending a whopping £44 billion (US$63billion) on new garments each and every year. That consumption alsogenerates 1.8 million tonnes (1.98 million tons) of waste material, and uses up 6.4billion m3 of water.

Researchers at Loughborough Universitybelieve that 3D printing, also known as additive manufacturing, could trulyrevolutionize the industry. They note that while the practice of making clothes hasbeen streamlined and manufacturing costs have been lowered, theunderlying processes and techniques haven't really changed since the19th century.

The new collaborative project is onlythe early stages, but the goal is to develop 3D printing technology,tailoring it to the garment industry. 3D printed textiles aren't anew concept, but the process of making them requires multiple stages.One of the biggest goals of the 3D Fashion project is to streamlinethat process, creating technology that can produce finishedgarments directlyfrom the raw materials (in this case a polymer) in a single step.

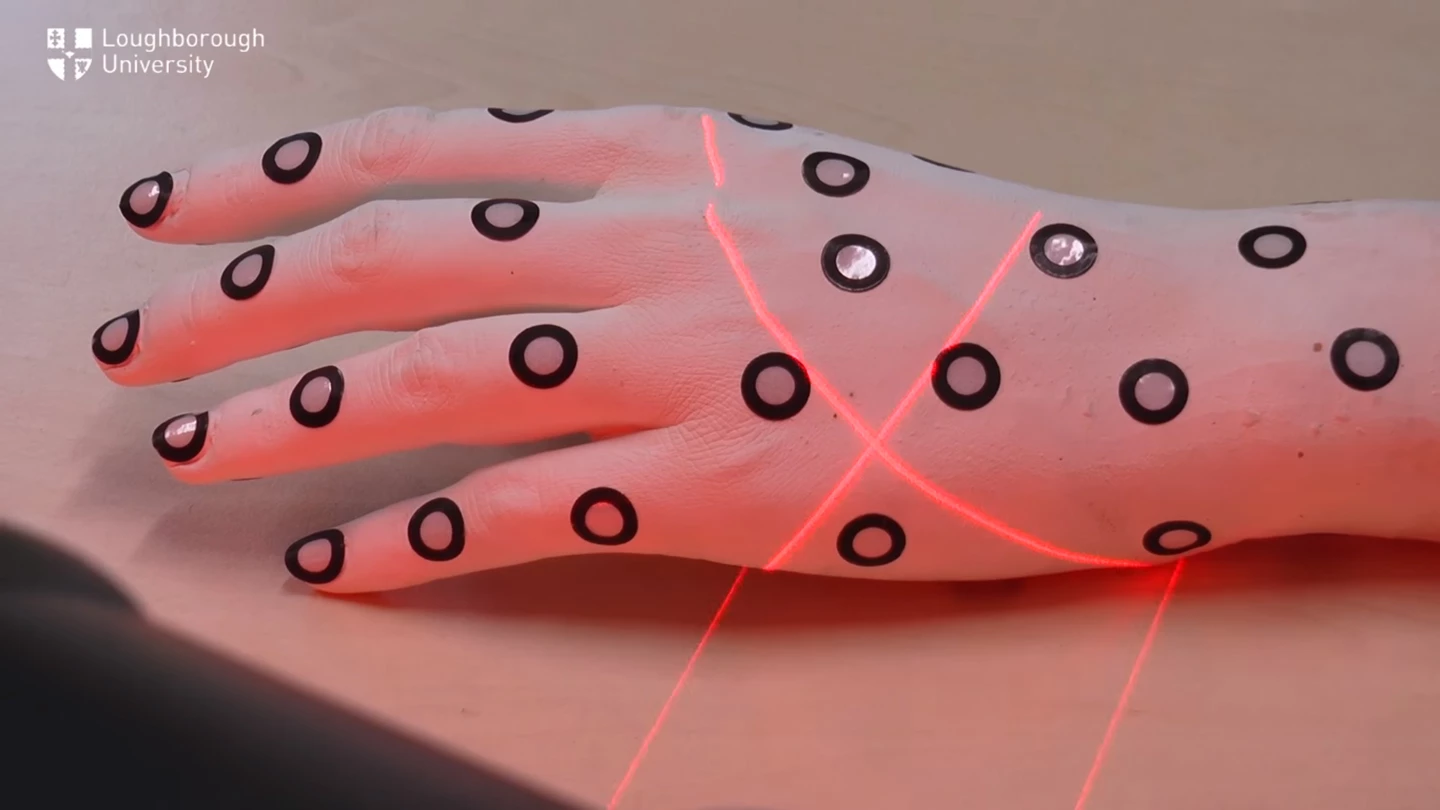

One big benefit of using additivemanufacturing for making apparel and footwear is that items could bemade specifically for individuals, with 3D scanners used to recorddata about the person, and that data then used to create bespokepieces. This sort of technology is already starting to become moremainstream, with devices like the XYZ scanner shown off at IFA 2015.

There's certainly a lot of work to dobefore the project's lofty goals can become a reality, but theresearchers are confident that by the end of the project, which isscheduled to last 18 months, the partnership will have come up with the one-step process needed to produce colored and finished garments.

"This landmark technology allows usas designers to innovate faster and create personalized,ready-to-wear fashion in a digital world with no geometricalconstraints and almost zero waste material," said LoughboroughUniversity's Dr. Guy Bingham. "We envisage that with furtherdevelopment of the technology, we could 3D print a garment within 24hours."

For more on the project, you can take alook at the video below.

Source: Loughborough University