Sculpting in a digital environment gives you the freedom to create impossibly balanced models and gravity-defying poses, and that's all well and good until you go to 3D print it. Depending on the severity of the model's shape, size, and pose, it may need to be glued to a heavy pedestal or even modified just to remain upright. That's a headache that's going away with an ingenious software solution called Make It Stand that quickly and easily optimizes a model's internal volume to balance it out, even when posed precariously.

Normally it is recommended to hollow out a model before printing it, as this can go a long way towards keeping it balanced, while also cutting down on the amount of material needed. The process is automated with most software, but Make It Stand offers a more in-depth method that allows you to interactively modify your model's internal cavity using voxels. If that's not enough to balance the model, the software will make minor adjustments to its shape through deformation as a last resort.

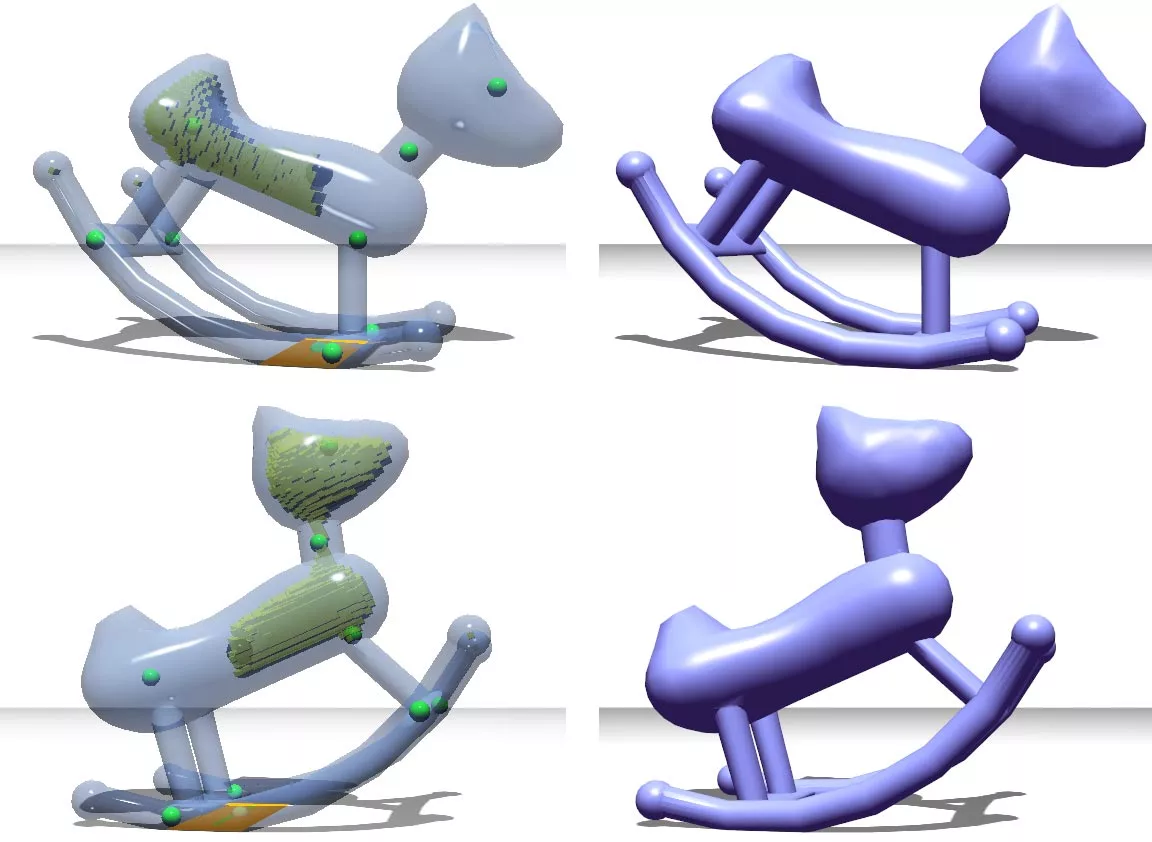

To get started you load a model, position it in the desired orientation relative to gravity, and set the contact points. Contact points can be where the model touches flat ground, or where it will have an attachment if it is going to be suspended by a string. This creates a support polygon, which is used to calculate the center of mass. Then the software builds a three-dimensional voxel grid that fits inside the model, with each voxel being full or empty. An algorithm selectively empties the voxels, moving the center of gravity to its most stable point even as the weight changes.

The main issue with this method becomes apparent if you print the model in a translucent material, because you'll be able to see a blocky void inside the model. That can't really be avoided, but it might be smoothed out in future versions of the software.

Another way to balance the model is by modifying its pose, which is done in conjunction with the above method to achieve the best results. You can easily set joint handles similar to building a skeletal rig used in computer animation to do so. Handles are automatically centered inside the model to translate, scale, and rotate specific portions of the model, and the software makes gradual changes in an attempt to retain the desired look of the model by comparing the original and modified positions of individual vertices.

The software was put to the test with a variety of toy-like models, which were then 3D printed. The results, which can be seen in the gallery and the video below, are pretty amazing.

Anyone with an interest in printing sculptural models would no doubt want to add Make It Stand to their software tool belt, but it's currently just a research project.

The Make It Stand team (Romain Prévost, Emily Whiting, Sylvain Lefebvre, and Olga Sorkine-Hornung at ETH Zürich's Interactive Geometry Lab and INRIA) presented its work this week at ACM SIGGRAPH 2013.

Source: Interactive Geometry Lab via 3ders

UPDATE (Aug. 30/13): The researchers have informed us that the software will be available for free on their website in the near future, so interested readers should watch the project page (first link in line above).