Over the past few years, the price of desktop 3D printers has been falling thanks to devices such as the uPrint, MakerBot, Printrbot and Cubify ). But designer Jon Buford's thoughtfully-conceived MakiBox looks to be the least expensive yet. He and his team have now pre-sold enough of the device to make the move from prototype to market and the result looks rather promising. If all goes well, the US$300 printers (plus US$50 for global shipping) could be available for delivery as soon as the end of the month.

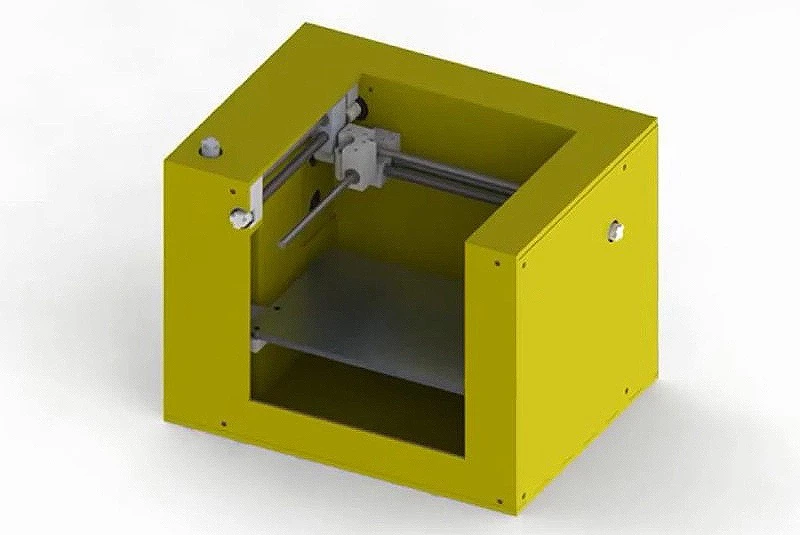

The 280 mm x 210 mm x 210 mm (11 x 8.27 x 8.27 in) self-contained MakiBox has a footprint about the size of a piece of standard letter paper, yet can build objects up to 150 mm x 110 mm x 110 mm (5.9 x 4.3 x 4.3 in) in size - about a quarter of the printer's overall volume. Replicator G, an open source 3D printing software application compatible with Windows, Mac and Linux, drives the printing process during which spooled 1 mm (0.04 in) diameter polylactide (PLA) plastic filament is melted and extruded in thin layers at 60-80 mm (2.36-3.15 in) per second.

The MakiBox will ship as a relatively easy-to-assemble kit that Buford says is "no more difficult than IKEA furniture." That means the the most difficult parts will come pre-assembled - no soldering iron needed. It comes with 1 kg (2.2 lb) of 1 mm PLA stock on two 0.5 kg (1.1 lb) spools. Extra plastic, also available in 3 mm (0.12 in) and 1.75 mm (0.07 in) diameters will sell for $20 per kilogram, a significant saving over the price currently charged for competitor 3D printers.

Now that the MakiBox A6 project is fully funded, it will be available through Makible, a crowdfunding site similar in concept to Kickstarter that Buford co-founded to help quickly fund and get products to market. He's kept the development process of his team's 3D printer unusually transparent as evidenced by the frequent video posts (see below) and blog updates on his site, perhaps to reassure investors who took an appreciable leap of faith by laying out the cash for an as-yet non-existent product. Makible claims it'll refund all investor money for projects that don't achieve their full-funding goal.

"I've got the extruder system almost complete," Buford told Gizmag. "The next step after that will be to do a final revision using what I've learned from this current prototype to make the production design, and start the production up. At this point, all the production parts will be CNC and lasercut parts, so will be very quick to go from final design to production." Indeed, it'll have to go speedily to make the late March deadline, but Buford is a man with a mission who seems seems determined to make it happen.

Check out the videos below to learn more about the MakiBox A6 from Jon Buford.

Source: Makible