British electric drive specialist Helix builds some of the most power-dense electric motors in the world. Now it's working to springboard that compact, power-packed design into a marine drive ecosystem it believes will help change the face (or at least underbody) of everyday recreational and utility boating. The company's all-new Pod Cartridge brings the e-drive components necessary to make 360-degree pod drives a widely available solution capable of increasing efficiency and boosting maneuverability across a huge market of vessels.

Evolved from the azimuth thruster systems dating back to the mid-20th century and beyond, electric pod drives serve as a flexible, decentralized form of marine propulsion that increases efficiency, improves maneuverability and frees up space in a ship's hull. Instead of relying on a large central engine to run a propeller via an extended driveshaft, and a separate rudder system for steering, these units integrate all of those powertrain and running gear components into a horizontally gimbaled subaquatic pod installed on the keel of the ship.

The pod then serves as both a propulsion and steering mechanism that includes 360-degree rotational capabilities made possible by the slip rings that deliver electricity. This full rotation allows each pod to direct thrust precisely where it's needed to move in the desired direction, making a separate rudder system unnecessary while vastly improving maneuverability to the point of giving massive ships the ability to turn in place, much like a torque-vectoring electric car does on land.

Beyond increased maneuverability, pod drives also boast improved efficiency, using their full rotational capabilities to direct thrust in the most efficient way for the current direction of travel and conditions while also smoothening out energy-sapping vibrations and eliminating the added drag of rudder components.

According to Swedish-Swiss multinational ABB Group, which now markets the Azipod – the very first electric pod drive launched in the early 1990s, open-water vessels commonly enjoy energy consumption reductions between 5 and 15 percent when propelled by an Azipod system, with decreases as much as 20 to 25 percent possible.

That's no small savings when talking about something like a cruise ship that sucks up hundreds of thousands, even millions, of gallons of fuel when pushing from port to port. A few years back, a study by Deltamarin found Azipod-driven ferries could save up to US$1.7 million in annual fuel costs.

That suite of advantages has established the pod drive as a popular solution for some of the largest seagoing vessels – cruise liners, container ships, tankers and ferries, to name a few. We've previously looked at how a pod's ability to rotate directional propulsion 180 degrees between a "pulling" orientation and a "pushing" orientation has been a particular boon to polar-ready icebreaking ships.

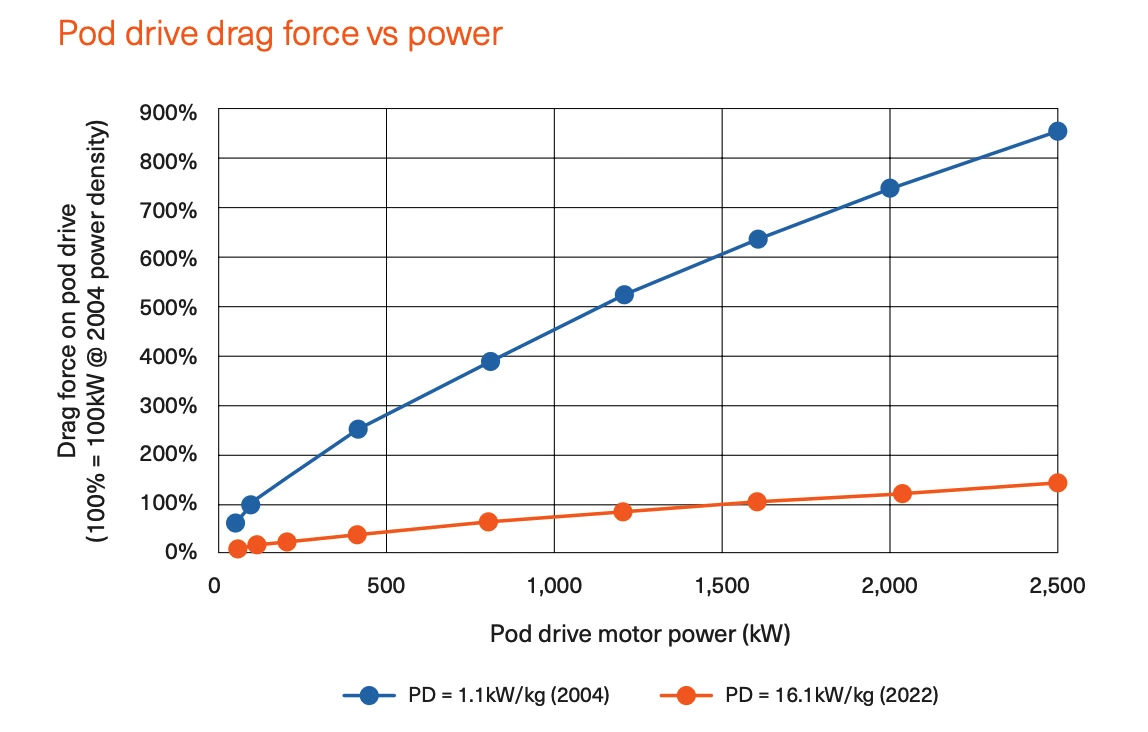

But Helix believes pod drives have loads of untapped downmarket potential, explaining that they have long been limited to use in large vessels because of the power density shortcomings of conventional electric motors. In order to achieve the high levels of power required to propel a ship, it's been necessary to install huge motors inside even huger underwater pods, inducing high levels of drag. It's only in the very large megawatt+ range that drag, as proportionate to power, decreases enough to realize the efficiency gains of pod propulsion. In smaller pods, the proportional drag becomes too high to overcome.

Helix is ready to shift the entire equation via its rapidly evolving electric motor topography, which creates high levels of power and torque from tiny, ultra-lightweight packages. While Helix's top-tier 25-kW/kg SPX177 motor was developed by its experimental division for a hypercar prototype, not optimized for mass market use, the SPC177 radial flux motor it plans to use for its marine pod ecosystem still offers a high density up to 9.7 kW/kg, putting out 300 kW of continuous power from a 31-kg (68-lb) package.

At that type of power density level, the drag induced by the pod body becomes trivial at sub-megawatt sizes, Helix reasons, opening the door for the efficient propulsion of small to midsize boats. In fact, the company goes so far as to say its small, powerful motor construction will allow shipbuilders to cut 70 percent of the drag as compared to traditional (massive) pod drives.

Rather than developing complete pods, Helix intends to create modular flexibility by supplying what it calls Pod Cartridges to builders of sub-megawatt, small to midsize recreational, commercial and passenger vessels. Each cartridge will be a plug-and-play set of pod internals for shipbuilders and propulsion systems manufacturers to fit within their own subaquatic pod structures and pair with propellers, battery systems, electric generators, and control software solutions specced for the specific requirements of the vessel in question.

Each of the launch cartridges will include an SPC177 motor packaged with an Xtrac gear reduction system, CAN bus interfaces, bearings and seals, and available Helix inverter.

"By freeing up deck space previously reserved at the transom for outboard motors, or interior space reserved for engine compartments and propeller shafts, our Helix Pod Cartridge offers the industry a generational chance to revisit how it designs vessels," Helix's chief marine engineer James Edwards said during last month's announcement, "all while unlocking more efficient travel and helping marine in its journey towards net zero emissions."

Helix gives examples of using the extra hull volume to make a trawler more comfortable and functional for fishermen or a yacht more relaxing and enjoyable for leisure customers.

Three sub-megawatt Pod Cartridge sizes will be available at launch: 100, 200 and 300 kW. The 100 and 200 models will be offered in both low- and high-torque variations, and Helix plans to eventually expand out the lineup to output sizes between 480 kW and 3 MW.

Given the limited ranges of battery-powered electric boats, you might be wondering how exactly marine operators power a conventional multi-megawatt electric pod motor. It isn't by mere battery, requiring an onboard electrical generation system using the likes of diesel fuel or hydro generation.

Similarly, Helix notes that Pod Cartridge customers will be able to develop their own power systems, whether comprising purely batteries or a series hybrid setup that develops electricity from a diesel generator or alternative source. Unsurprisingly, the company expects customers to skew toward hybrid systems in the initial stages.

Source: Helix