Nautical disruptor Sharrow Marine has been hard at work fast-expanding its lineup of innovative twisted-loop propellers, releasing tweaked models for new applications while also ramping up overall production. A year ago, that work saw it launch the MX-A propeller for smaller outboards, effectively cutting pricing by more than half compared to previous launches. Now it's doing it again with the AX, smashing downward through the four-figure floor for the first time with a propeller designed for even smaller outboards and kicker motors. Buyers seeking to put the company's striking, efficiency-boosting loop-blades to work can now do so for well under $1K.

Officially introduced on Tuesday, the all-new Sharrow AX propeller follows the MX-A in using a lightweight aluminum construction that delivers corrosion-resistant performance without the expense of stainless steel. Unlike with the MX-A. The AX slides below the targeted 40-hp+ market of the MX-A and is designed specifically for small outboards ranging between 6 and 30 hp.

"With the launch of the Sharrow AX, we’re proud to introduce our technology to the small-engine market," said founder and CEO Greg Sharrow. "Whether used as a primary prop on a small outboard or as an auxiliary kicker for trolling, the AX offers smoother handling, quieter operation and unmatched fuel efficiency."

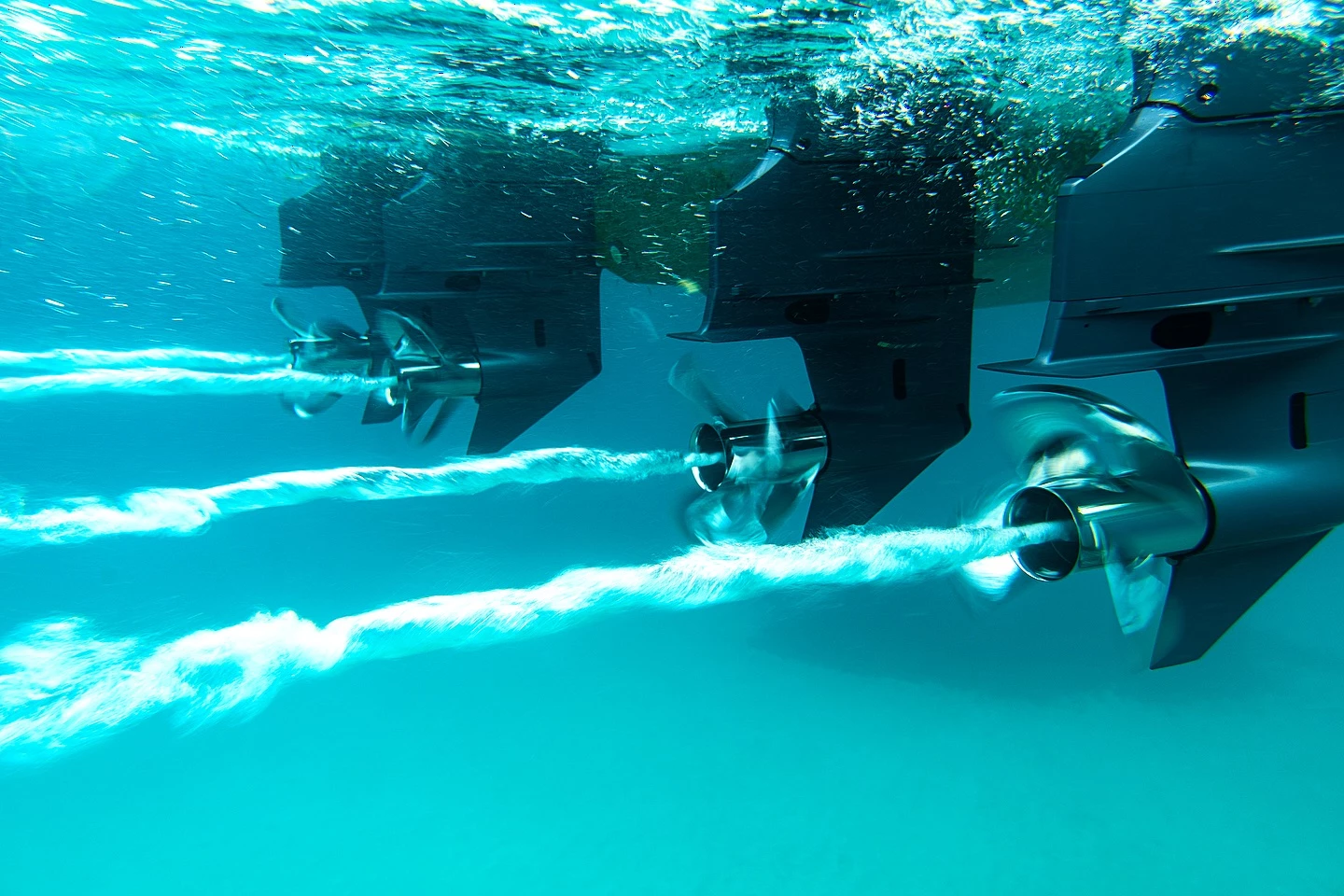

Sharrow has long stated its specially formed propellers offer efficiency improvements up to 30% over traditional props and noise reduction as high as 80%, providing smoother, quieter performance all over the water. They do so by greatly reducing the tip vortices and cavitation that standard propeller blades create. Sharrow propellers are also designed to improve maneuverability and control.

The reviews we've seen on previous Sharrow releases from sources like BoatTest and Boating Magazine have been largely positive. As is to be expected, actual on-water performance, efficiency gains and optimal RPM ranges vary, with some reporting efficiency improvements closer to 10% or less than 30%. But from what we've read and watched, efficiency gains, quieter operation, reduced vibration, smooth, stable handling, improved planing and enhanced maneuverability are commonly reported.

Of course, there's still that US$1,600 to $5,000 price tag to contend with. Recouping that investment on a recreational boat is going to be a long road, no matter how you cut it. So are the performance, handling and noise-reducing benefits worth the spend?

That'll be a question to which answers vary widely on a case-by-case basis and often inspire an immediate, resounding "NO!!"

The good news is, Sharrow has been continually dragging the price tag down, working with new materials, releasing new model variants aimed at less expensive outboards, and expanding production and distribution. The AX is ultimately aimed at fishing and general recreational boats, and at $795 to $995, is Sharrow's least expensive propeller yet ... by a long shot.

Of course, that pricing is relative, and while the base AX price is right around 50% lower than the $1,595+ MX-A, the 6- to 30-hp outboard and the smaller boat powered by it, will also be well less expensive than the motors and vessels on which the MX-A finds use. So that $795 will seem like a much larger cost than it would for the owner of a larger, more powerful boat.

So will Sharrow gain a few more "Yes" responses with its latest prop? Time will tell.

The AX is available to order directly from Sharrow now for Mercury and Yamaha outboards that fall in the targeted horsepower range. Lead time is estimated at six to eight weeks.

Source: Sharrow Marine