Thanks to advances in materials and electronics, we are starting to see how our clothing might one day do more than keep us warm or protect us from the elements. Scientists at Chalmers University of Technology have offered a compelling new example of what might be possible in this area by developing a new thread made of conductive cellulose, which can be worked into textiles that generate electricity for all kinds of purposes.

“Miniature, wearable, electronic gadgets are ever more common in our daily lives," says Sozan Darabi, doctoral student at the Department of Chemistry and Chemical Engineering at Chalmers University of Technology. "But currently, they are often dependent on rare, or in some cases toxic, materials. They are also leading to a gradual build-up of great mountains of electronic waste. There is a real need for organic, renewable materials for use in electronic textiles."

Darabi and the team had previously had some success developing electrically conductive fibers made from silk, but have now turned their attention to cellulose, which they say carries huge potential.

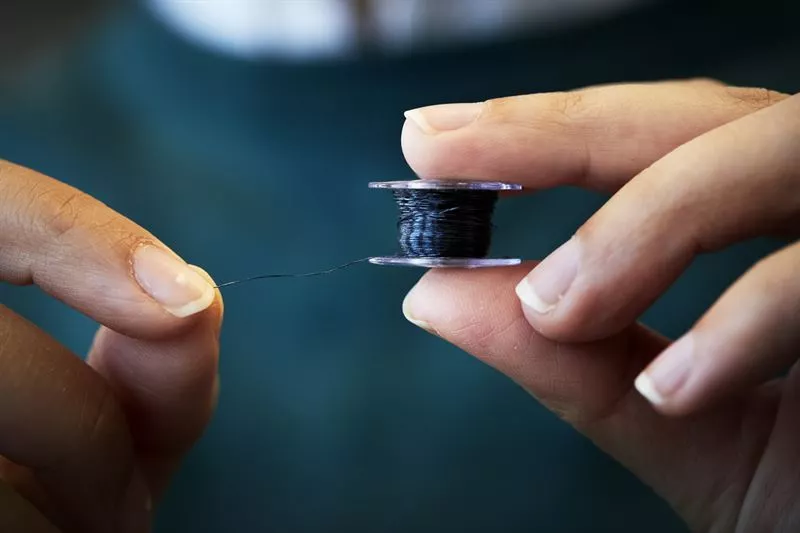

The technology starts with wood-based cellulose threads, which are dyed with an ink based on an electrically conductive biocompatible polymer by the name of PEDOT:PSS. This "roll-to-roll" coating process turns the thread into a conductive one, so much so that the team claims its creation boasts a record high conductivity for a cellulose thread, which can be boosted even further with the addition of silver nanowires.

The resulting thread can be sewn into a fabric with a household sewing machine to produce a thermoelectric textile that generates electricity when subjected to heat on one side. The team offers the example of body heat, claiming that with a temperature differential of 37 °C (98 °F) (assuming the person is standing in the freezing cold), the textile can produce around 0.2 microwatts of electricity.

“This cellulose thread could lead to garments with built-in electronic, smart functions, made from non-toxic, renewable and natural materials,” says Sozan Darabi.

These kinds of garments could prove useful in a range of areas, but the scientists see particular potential in medical care where they could be used to monitor different health metrics.

The use of cellulose should add to the recyclability of the finished product, though currently the threads can only endure five machine washes without losing their electrical conductivity.

“Cellulose is a fantastic material that can be sustainably extracted and recycled, and we will see it used more and more in the future," says Christian Müller, research leader for the study. "And when products are made of uniform material, or as few materials as possible, the recycling process becomes much easier and more effective. This is another perspective from which cellulose thread is very promising for the development of e-textiles."

The research was published in the journal ASC Applied Materials & Interfaces.