Tubular structures that fold flat for storage may not take up much room in that form, but they also tend not to be very strong when deployed. That isn't a problem with an experimental new type of tube, that's inspired by both origami and bamboo.

First of all, flat-pack tubes do indeed already exist.

They're utilized in applications such as pop-up emergency shelters, medical implants, and even booms that unfurl from solar arrays in outer space. In all cases, the idea is that the tubes maintain a low, space-saving profile until they're deployed in the place that they're needed.

Unfortunately, because the tubes typically have two fold lines running laterally along either side, they're not as strong as conventional non-flat-pack tubes. This means that if they're utilized in a load-bearing structure, for instance, they're more likely to buckle under pressure.

That's where the new "curved-crease origami" tube design comes in.

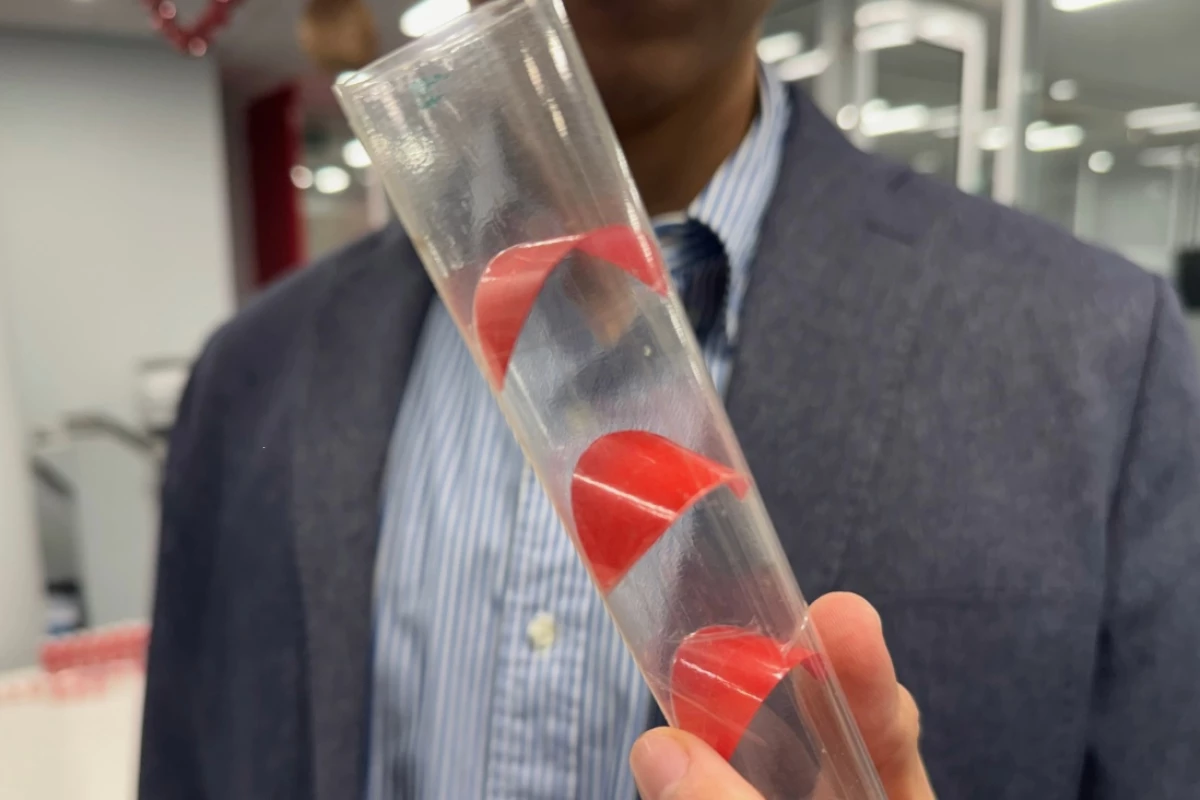

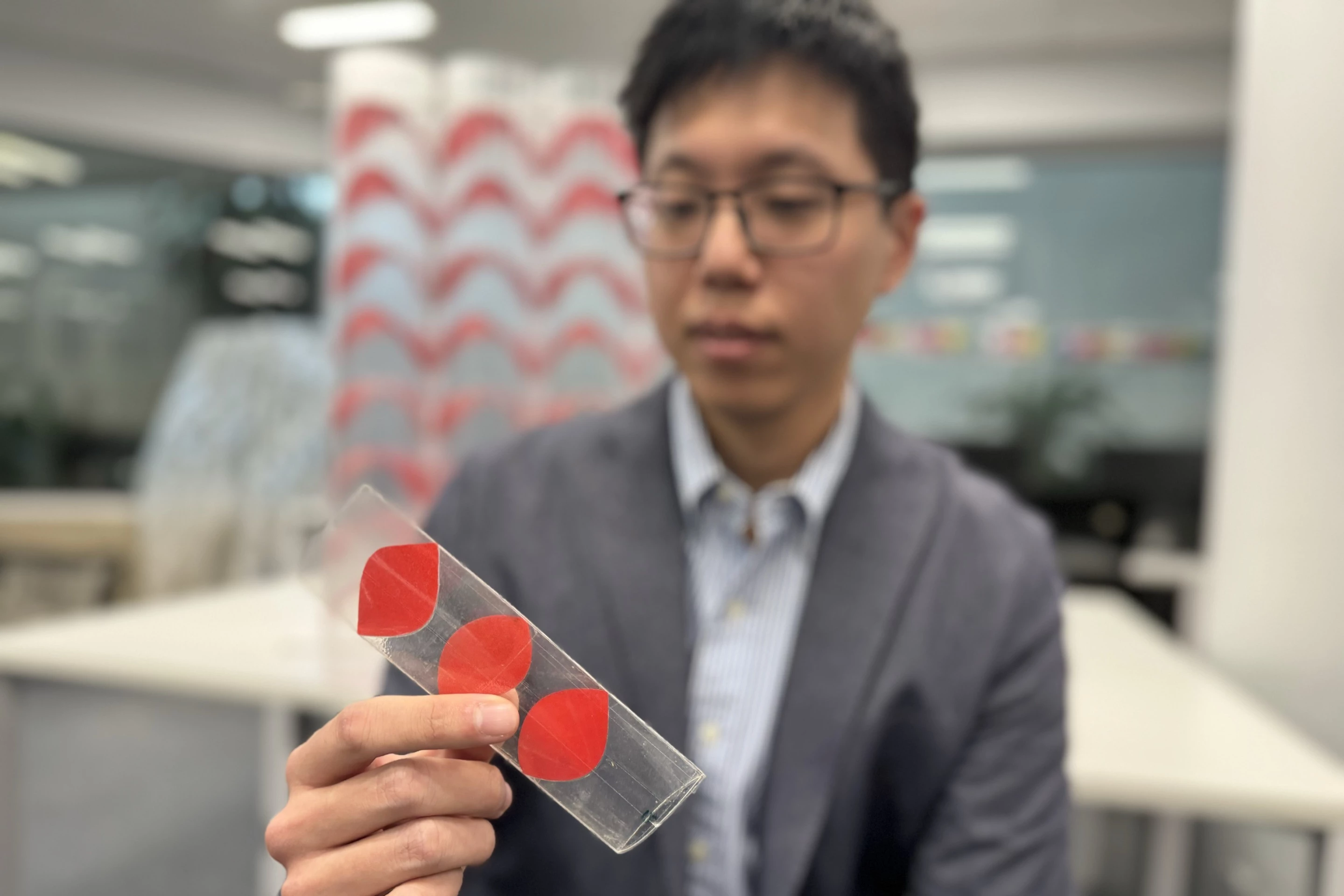

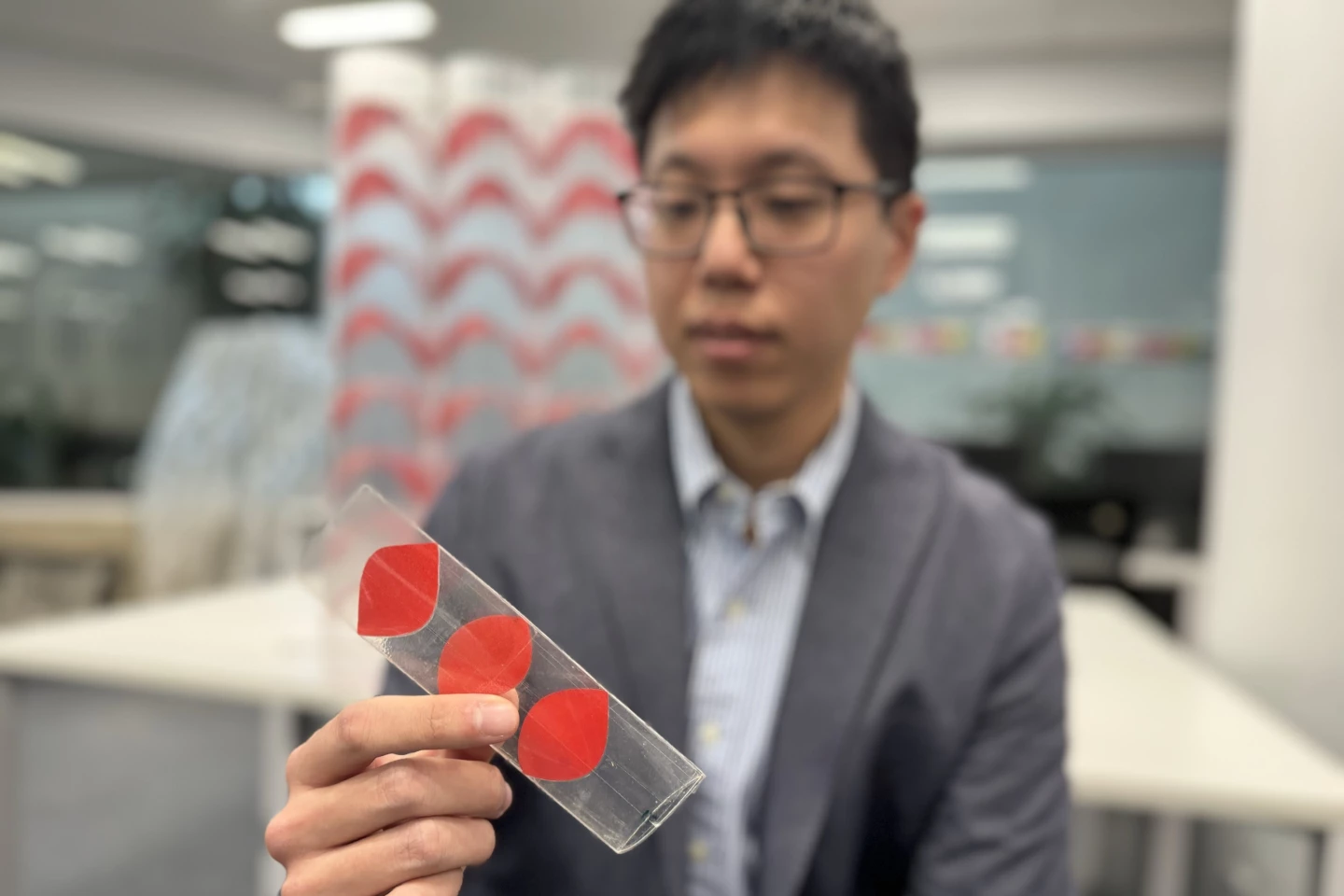

Developed by a team of researchers at Australia's RMIT University, the technology still utilizes polymer tubes that get folded flat, but those tubes aren't completely hollow. Instead, each tube has a row of laser-cut polyethylene discs inside. The internal structure of these discs makes them bistable, meaning that they can rest in either of two states.

When the tube is flattened, the discs inside of it are likewise in a flat state. Applying pressure to either side of the tube at its fold lines, however, causes the discs to pop into a curved state in which they press out against the inner walls of the tube.

Not only do they now hold the tube completely round and open, they actually lock in place to keep it that way. Stalks of bamboo employ a similar inner structure.

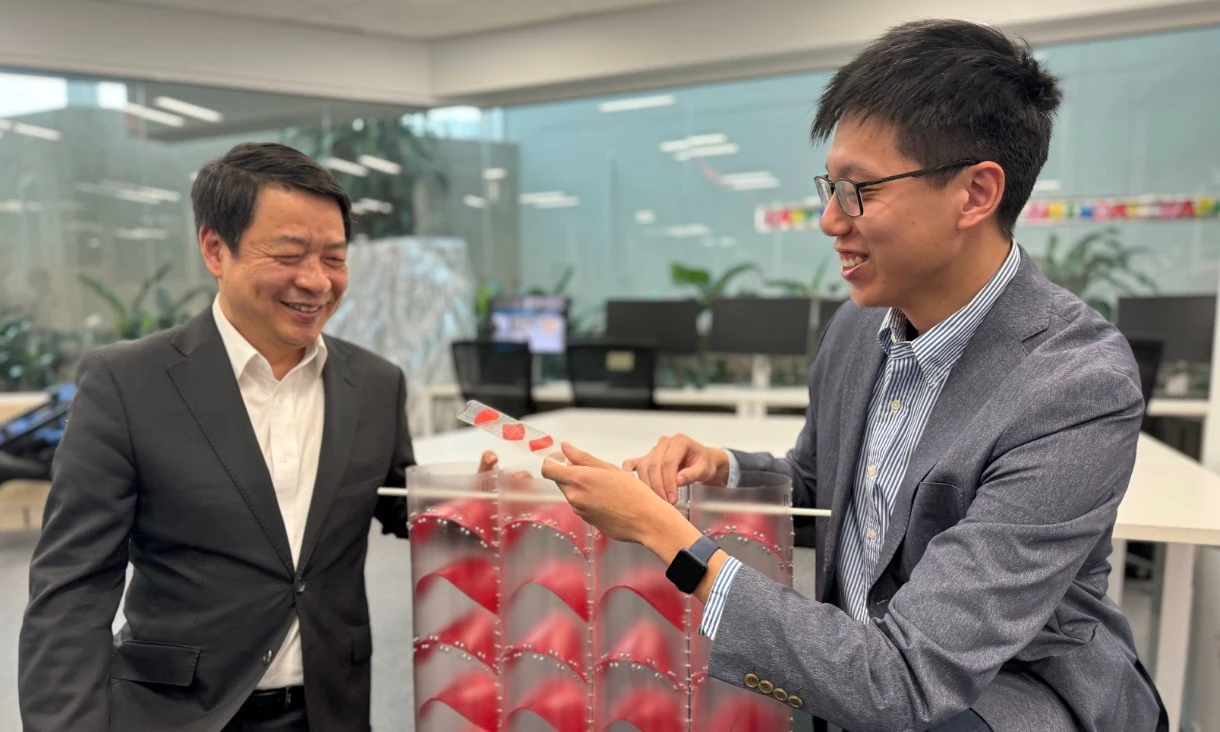

In a demonstration of the technology, the scientists built an 800 x 520-mm (31.5 x 20.5-in) platform consisting of four of the tubes arranged side-by-side with a thin panel laid on top. Even though the platform weighed just 1.3 kg (2.9 lb), it was strong enough to support the weight of a 75-kg (165-lb) person without deforming – even when suspended like a bridge.

"Our research not only opens up new possibilities for innovative and multifunctional structural designs, but it can also significantly improve existing deployable systems," says Prof. Mike (Yi Min) Xie, who led the study along with Dr. Jeff (Ting-Uei) Lee.

The scientists now plan on experimenting with different tube shapes and materials, and with different applications of force such as bending or twisting actions.

A paper on the research was recently published in the journal PNAS.

Source: RMIT University