Ordinarily, if a window goes around the corner of a building, it's made of two flat panes of glass that are joined together by a metal rail or glue. Now, though, German scientists have developed a method of bending a single sheet of glass to a 90-degree angle – without affecting its optical properties.

Although panes of glass can already be heated and then bent to a certain extent, very sharp angles have reportedly not been previously possible. Additionally, because the usual process involves heating the entire sheet to the point that it becomes soft and malleable, deformations can form at the points where the glass is supported in the oven.

In order to get around those limitations, researchers from the Fraunhofer Institute for Mechanics of Materials devised a technique which begins with a flat pane of glass being placed in an oven that's preheated to about 500 ºC (932 ºF). This is just below the "transition point" at which glass becomes malleable, so the oven's supports don't produce any deformations.

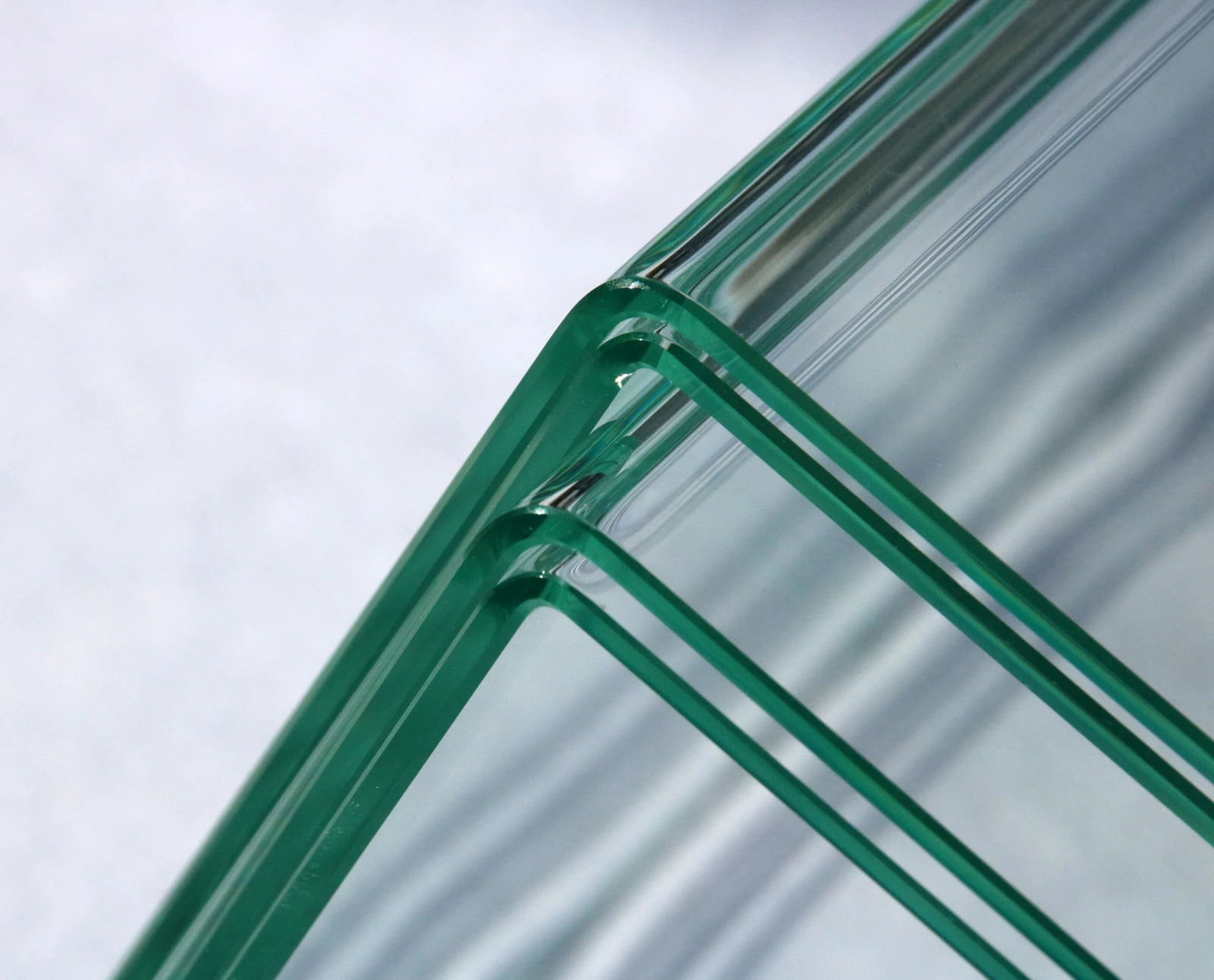

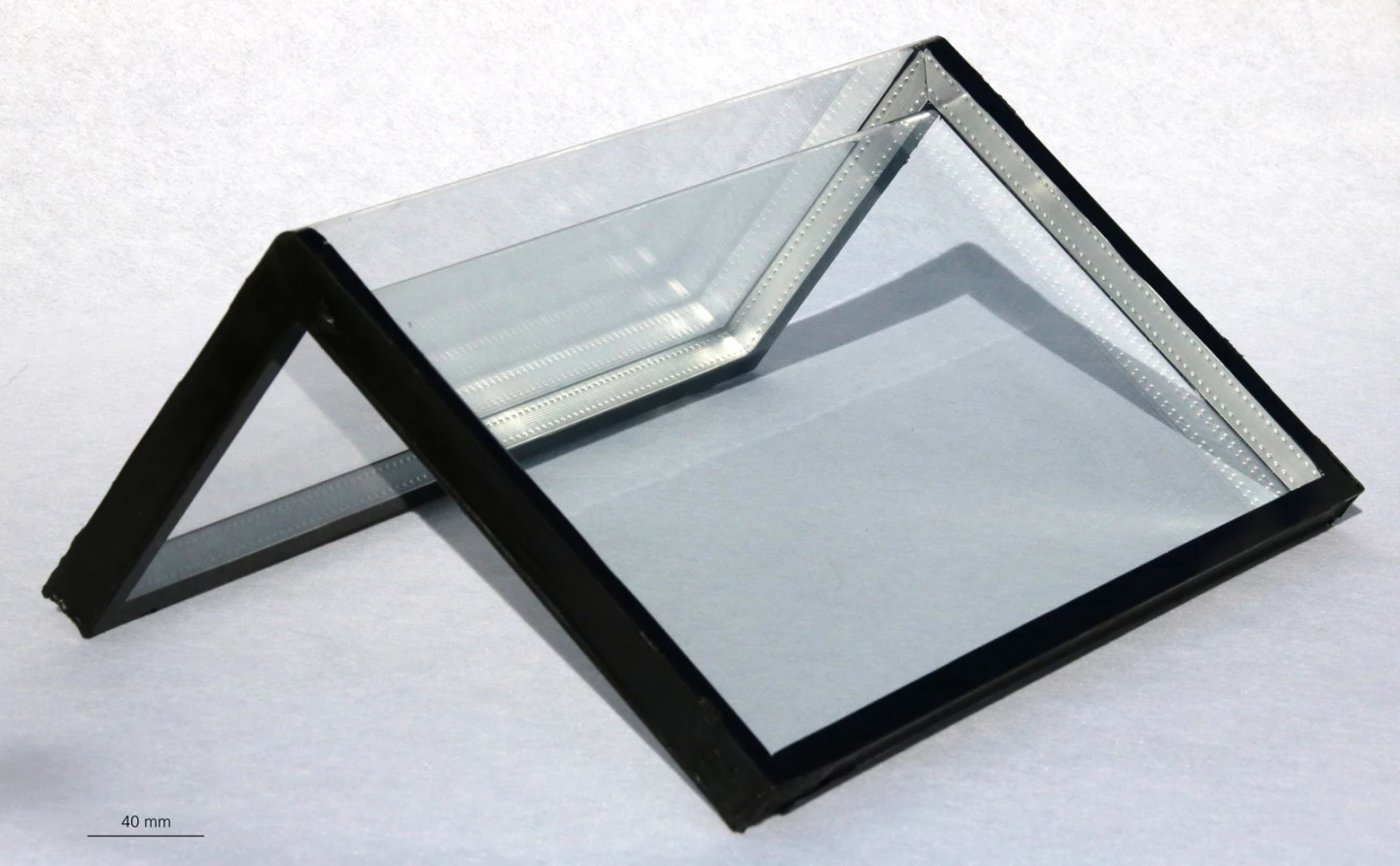

A mirror-guided laser is then used to heat the glass a little bit more, but only along a straight line going down the middle of the sheet – the rest of the pane stays at 500 degrees. As a result, the glass becomes soft only along that one line. When the supports are subsequently removed from beneath one side of the pane, gravity causes the sheet to bend along the softened line, naturally going to a 90-degree angle. Once the bent glass cools, it becomes entirely rigid again.

Utilizing their current lab equipment, the scientists have so far been limited to panes measuring a maximum of one square meter (10.8 sq ft). They are therefore looking for industrial partners who may be interested in commercializing the technology for use with larger sheets.

It is hoped that the glass-bending system may ultimately find applications not only in architecture, but also in fields such as medicine, where it could be used to produce gap-free glass surfaces that are resistant to colonization by germs.

Source: Fraunhofer