Concrete is the world's most manufactured item, with more than 25 billion tons used in construction each year. It's also responsible for consuming vast quantities of non-renewable resources, and spewing out 8% of all greenhouse gas emissions annually. So any steps we can take towards reducing the impact of its production on the planet is a worthwhile effort.

To that end, researchers in South Australia have found a way to funnel the byproduct of another destructive process – lithium mining – into making stronger and more durable concrete.

The challenge with lithium mining is that we depend heavily on this element to manufacture batteries for electronics and zero-emission electric vehicles – but the process of extracting it is extremely taxing on the environment. It has to be mined out of hard rock deposits containing minerals like spodumene ore, and this produces a lot of waste.

In particular, producing one ton of lithium hydroxide monohydrate generates about 7-10 tons of a byproduct called delithiated β-spodumene (DβS), but its uses haven't been well understood thus far. That results in it being disposed as hazardous waste, which poses environmental risks on top of the damage already caused by getting lithium out of the ground.

Engineers from Flinders University found that DβS exhibits pozzolanic properties, which means it reacts chemically to enhance the strength and durability of concrete by making it less permeable and also resistant to corrosion. Their study revealed when used as a binding agent in producing concrete, DβS can significantly improve mechanical performance and long-term resilience.

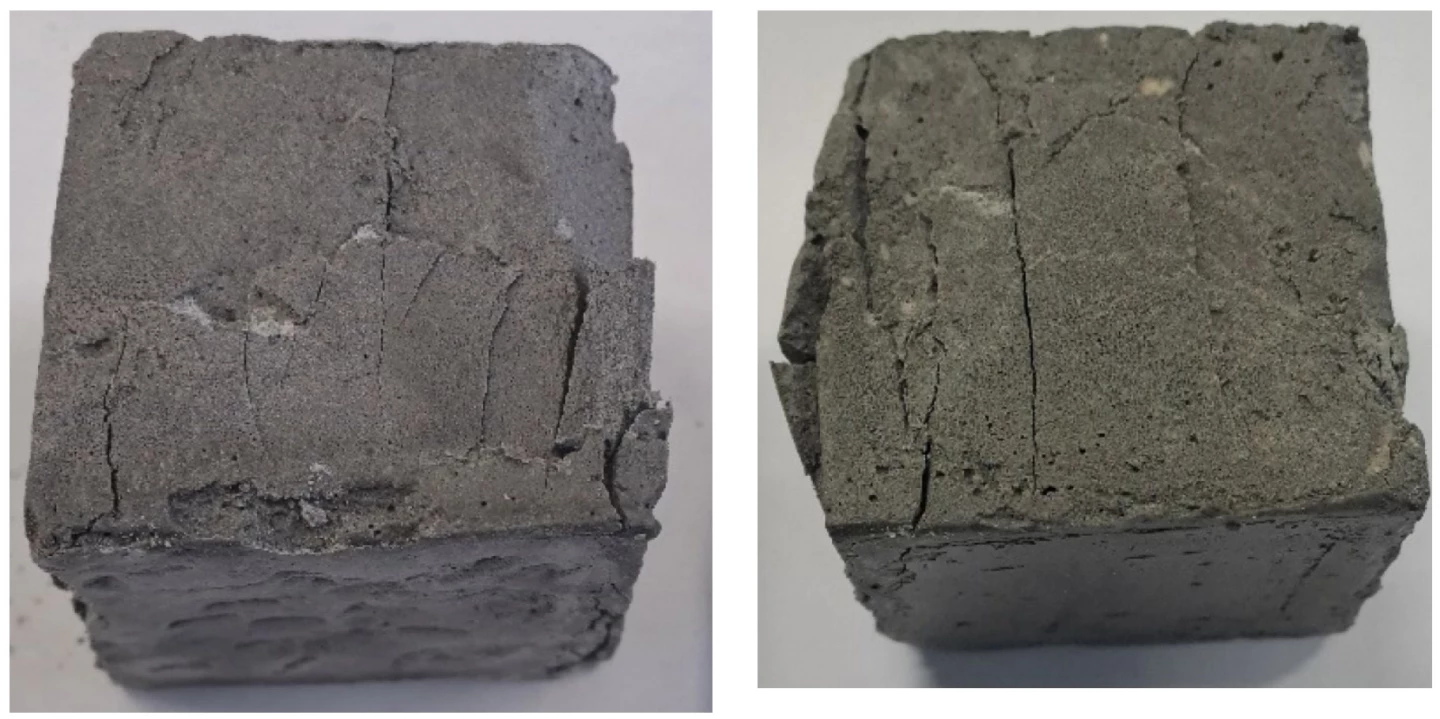

The team essentially replaced fly ash – a waste product from coal combustion – in creating geopolymer paste which acts as a binder in concrete. Replacing 25% of the fly ash content with DβS using an optimal alkaline activating solution ratio resulted in a 34% increase in the strength of concrete, compared to an equivalent mix with 100% fly ash. Adjusting the mix ratio of alkaline activating solutions led to a strength increase of 74%.

That shows that DβS can help produce concrete that's stronger than the usual stuff made with fly ash. It's the result of a denser and more robust internal structure of the concrete after 28 days of curing.

"With lithium refining responsible for generating increased volumes of DβS, the capability to reuse this in construction offers a sustainable solution that will reduce industrial waste, prevent potential soil and groundwater contamination, and support circular economic practices in the mining and building sectors," explained structural engineer Dr. Aliakbar Gholampur, who led the study that appeared in the journal Materials and Structures last month.

Dr. Gholampur has been at this for a while now. Back in 2022, he led a study showing how geopolymers reinforced with natural fibers and waste-based sands could feature in new-age concrete mixes with comparable strength and durability.

If you're into sustainable concrete, take a look at our previous stories on the material, including this one about recycling waste concrete from construction sites for new projects, a method for using old concrete in steel-processing furnaces to produce reactivated zero-carbon cement, and a 10x improvement on the already radical concept of a concrete battery.

Source: Flinders University