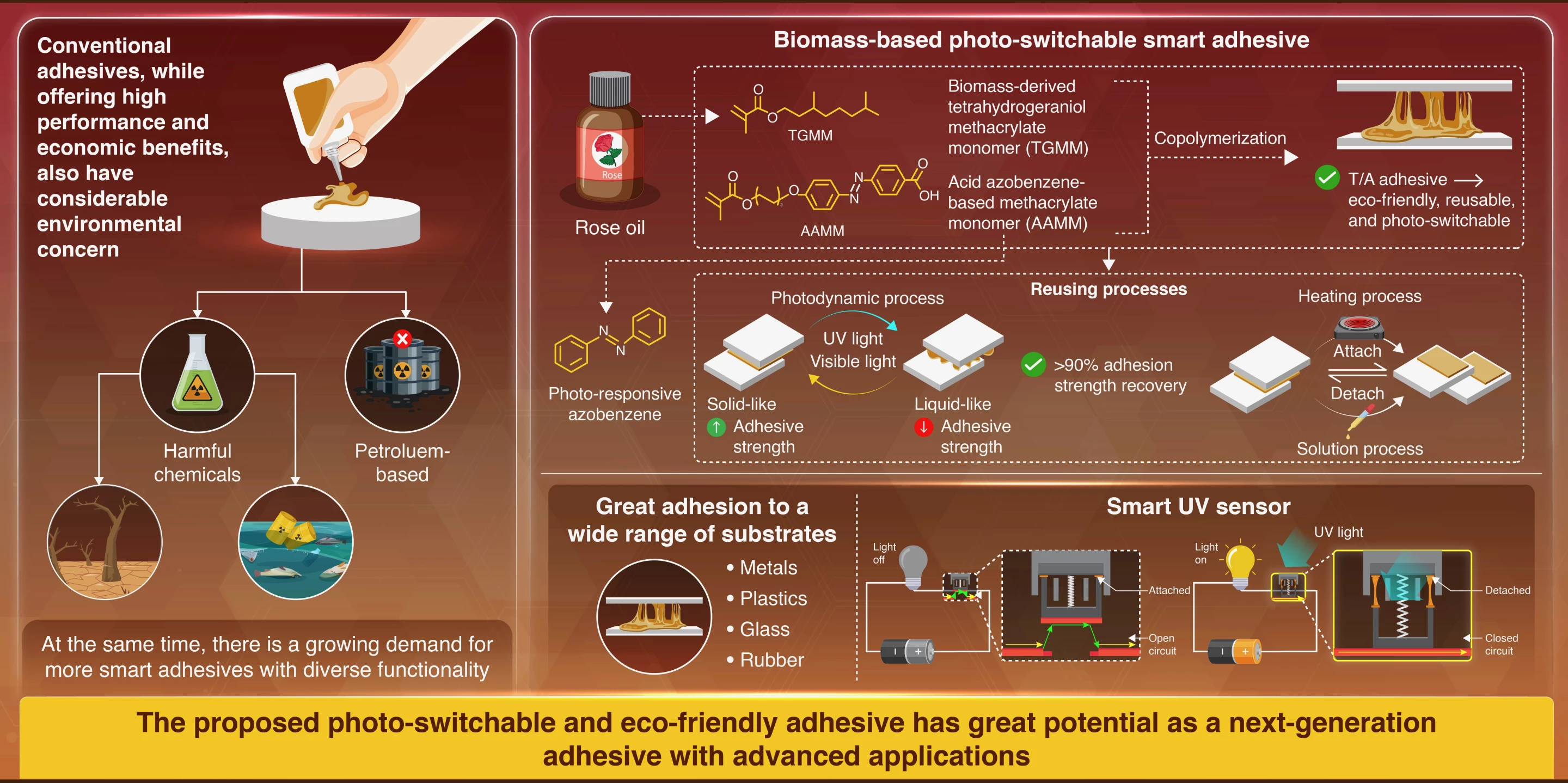

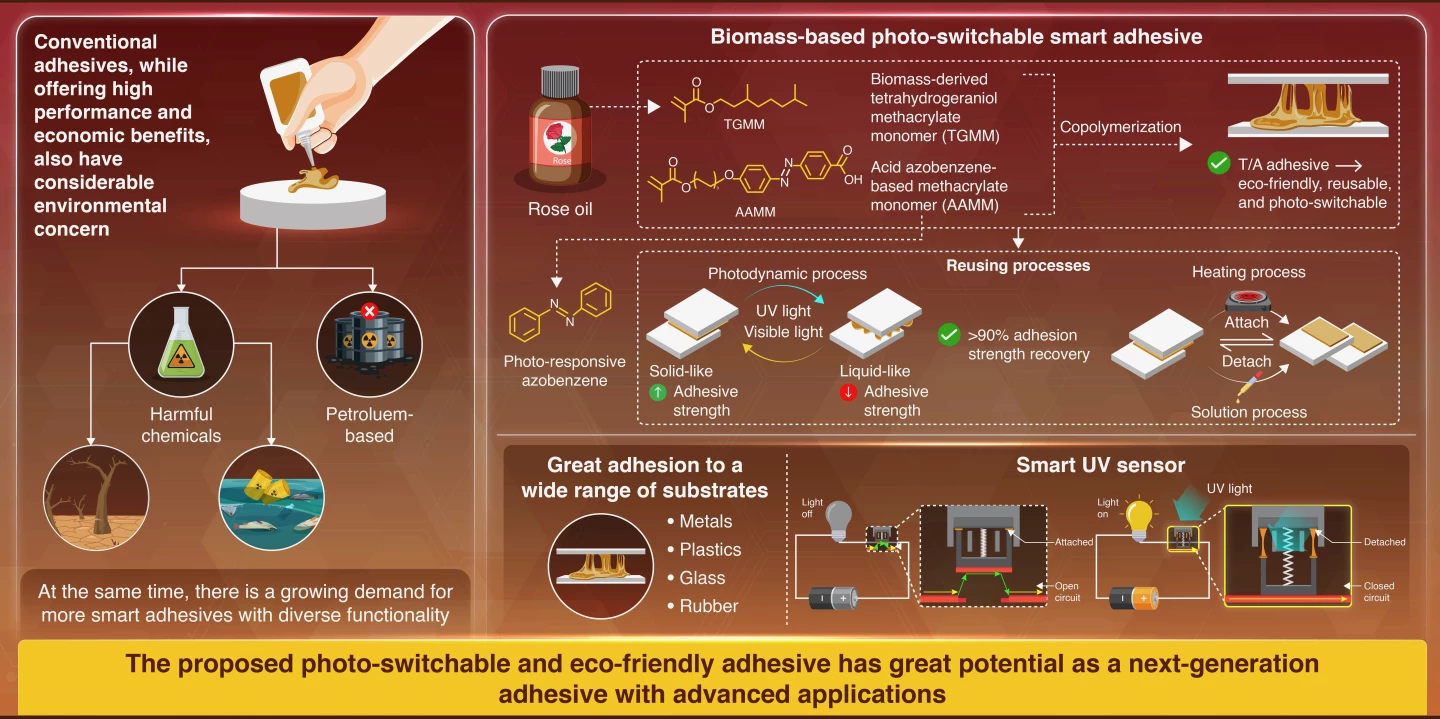

Electronics that can't be easily dismantled for recycling aren't very eco-friendly, nor are petroleum-based adhesives. Scientists have set about addressing both issues, by developing a switchable adhesive made mainly of rose oil.

Most commercial adhesives are made to stay permanently set once bonded, so electronics or other goods that are assembled using them are quite difficult to take apart for recycling.

With that problem in mind, scientists have developed "smart" adhesives that can be switched back and forth between bonding and non-bonding states. Unfortunately, many of those substances have still tended to be made of petroleum byproducts, the extraction and refining of which are notoriously environmentally unfriendly.

That's why Prof. Kwang-Un Jeong, PhD Student Mintaek Oh and colleagues from Korea's Jeonbuk National University looked to a tetrahydrogeraniol methacrylate monomer (TGMM). Derived from rose oil, the monomer was already known for being flexible, mechanically stable, and biodegradable.

The scientists combined the TGMM with an acid azobenzene-based methacrylate monomer (AAMM) made up of azobenzene, carboxylic acid, and methacrylate. AAMM was already known for its reversible photo-switchable behavior, in which exposure to different wavelengths of light causes it to change states.

The resulting "T/A adhesive" copolymer is made up of 95% TGMM and just 5% AAMM. When exposed to ultraviolet light, it takes on a liquid form, allowing it to be applied to materials such as metal, plastic, rubber, glass, cork, and paper. When subsequently exposed to visible light, it becomes solid, forming a firm bond.

To turn it back to liquid – thus releasing the bond – you just apply more UV light. When it rebonds afterwards with exposure to more visible light, it retains over 90% of its original adhesive strength.

The adhesive strength of the T/A copolymer can also be switched off and on by heating it to 500 ºC (932 ºF) then allowing it to cool, or by applying a solvent such as chloroform then allowing it to evaporate.

Along with its integration in easier-to-recycle electronics, the adhesive could have some other uses. For instance, the scientists utilized it in a UV light sensor, in which the adhesive holds a spring that maintains an open electrical circuit. If that switch is exposed to ultraviolet light, the adhesive gives out and releases the spring, closing the circuit and allowing an indicator light bulb to illuminate.

"Our smart, reusable adhesive is promising for a wide range of practical applications," says Mr. Oh. "It can play a valuable role in environmental monitoring, smart electronics, and adaptive assembly systems, where controllable and reusable adhesion is critical. It could also enable reusable light-responsive smart packaging, wearable devices with detachable sensors, and reconfigurable robotic components."

A paper on the research was recently published in Chemical Engineering Journal.

Source: Jeonbuk National University