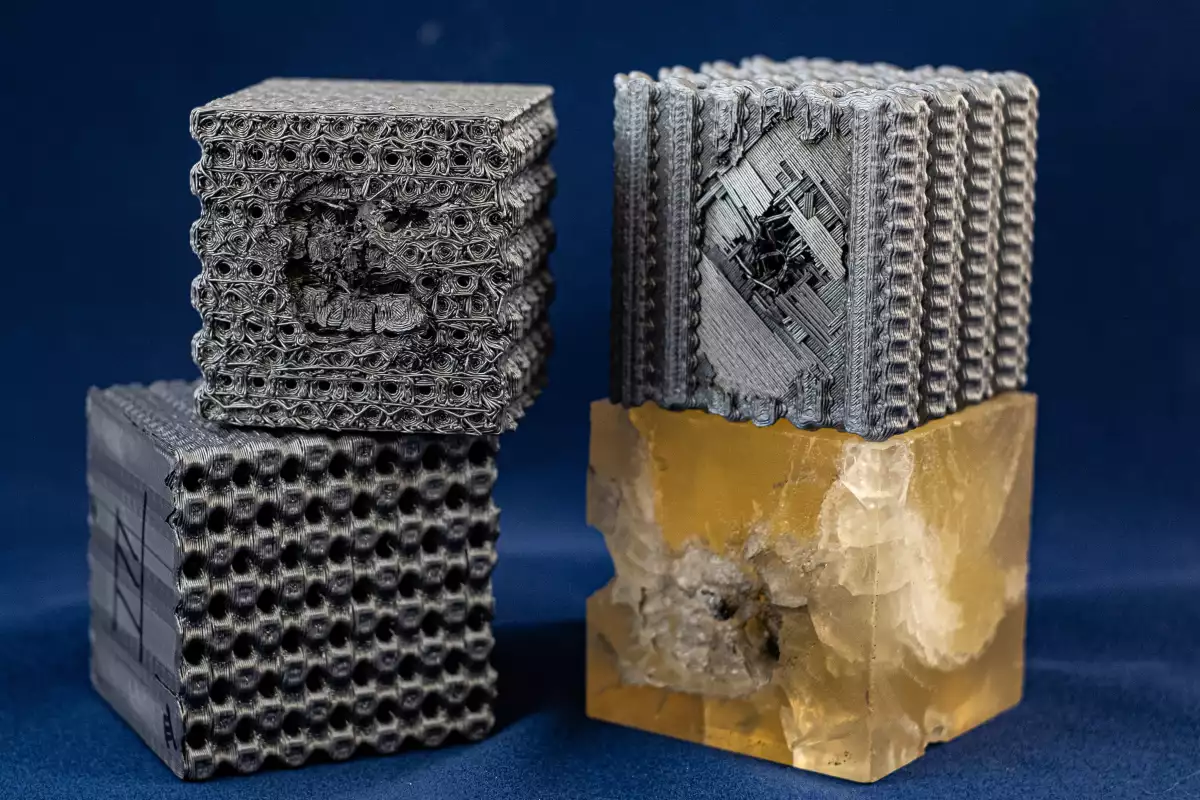

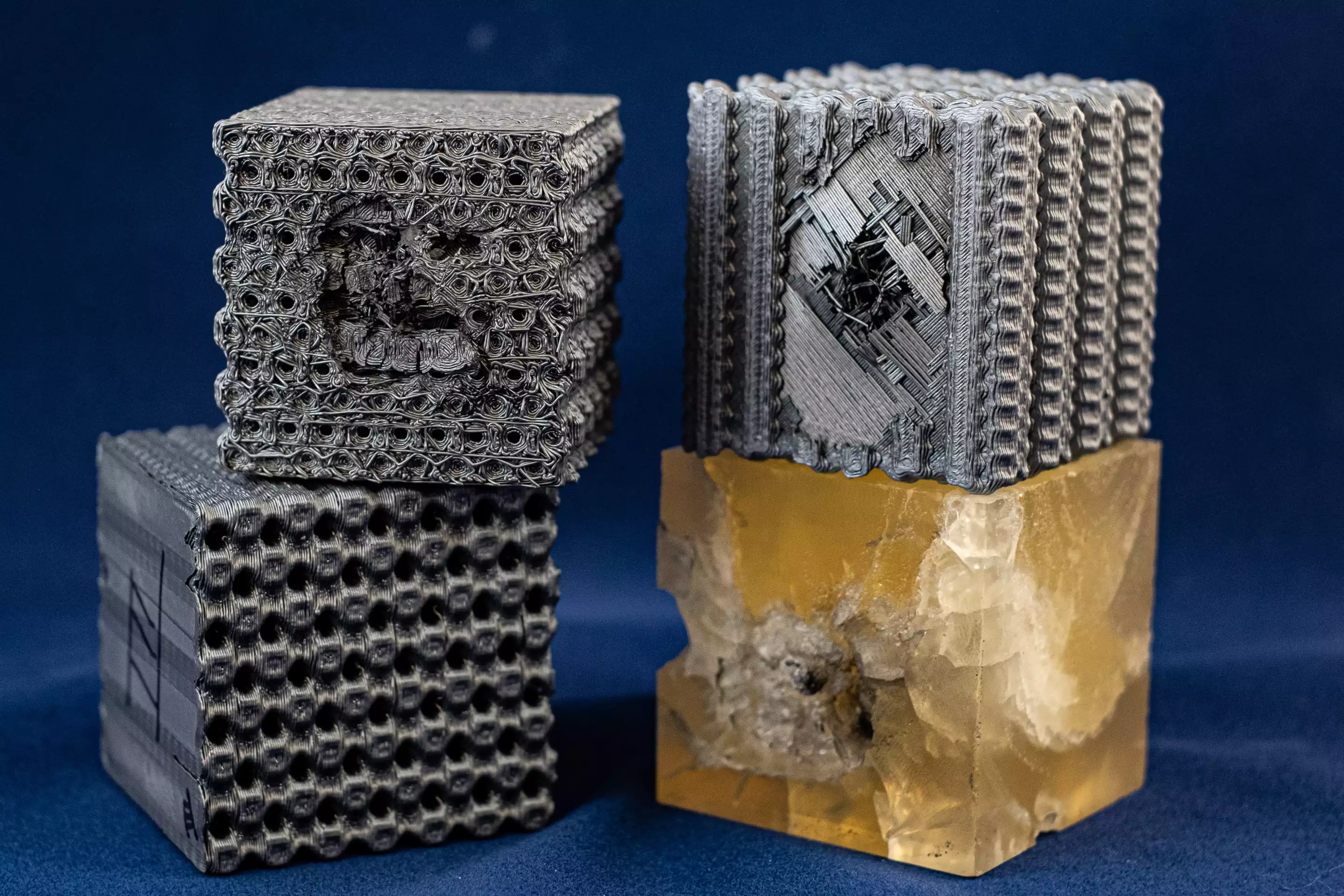

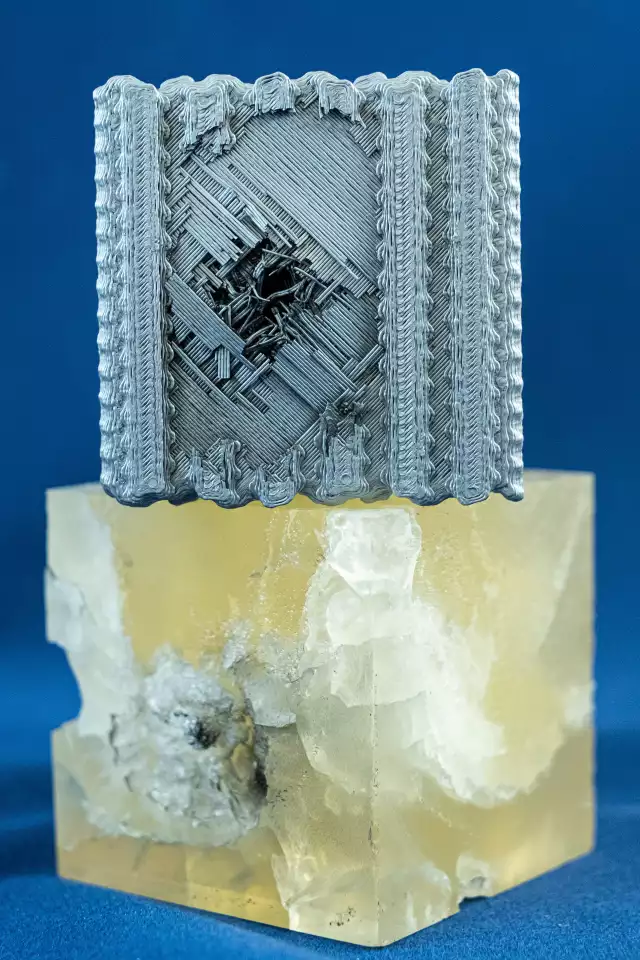

In exploring the properties and potential of a theoretical material, scientists at Rice University have developed a real structure with some very real stopping power. The team’s 3D-printed cube of latticed polymers is littered with holes, but in testing it proved to be nearly as hard as a diamond and capable of stopping bullets with impressive effectiveness.

The starting point for this experimental material is what as known as a tubulane. First dreamt up in 1993, tubulanes are intricate structures of cross-linked carbon nanotubes that could offer incredible strength, according to calculations, but an effective manufacturing method to actually produce them has evaded scientists so far. The advent of 3D printing, however, is opening up some interesting possibilities.

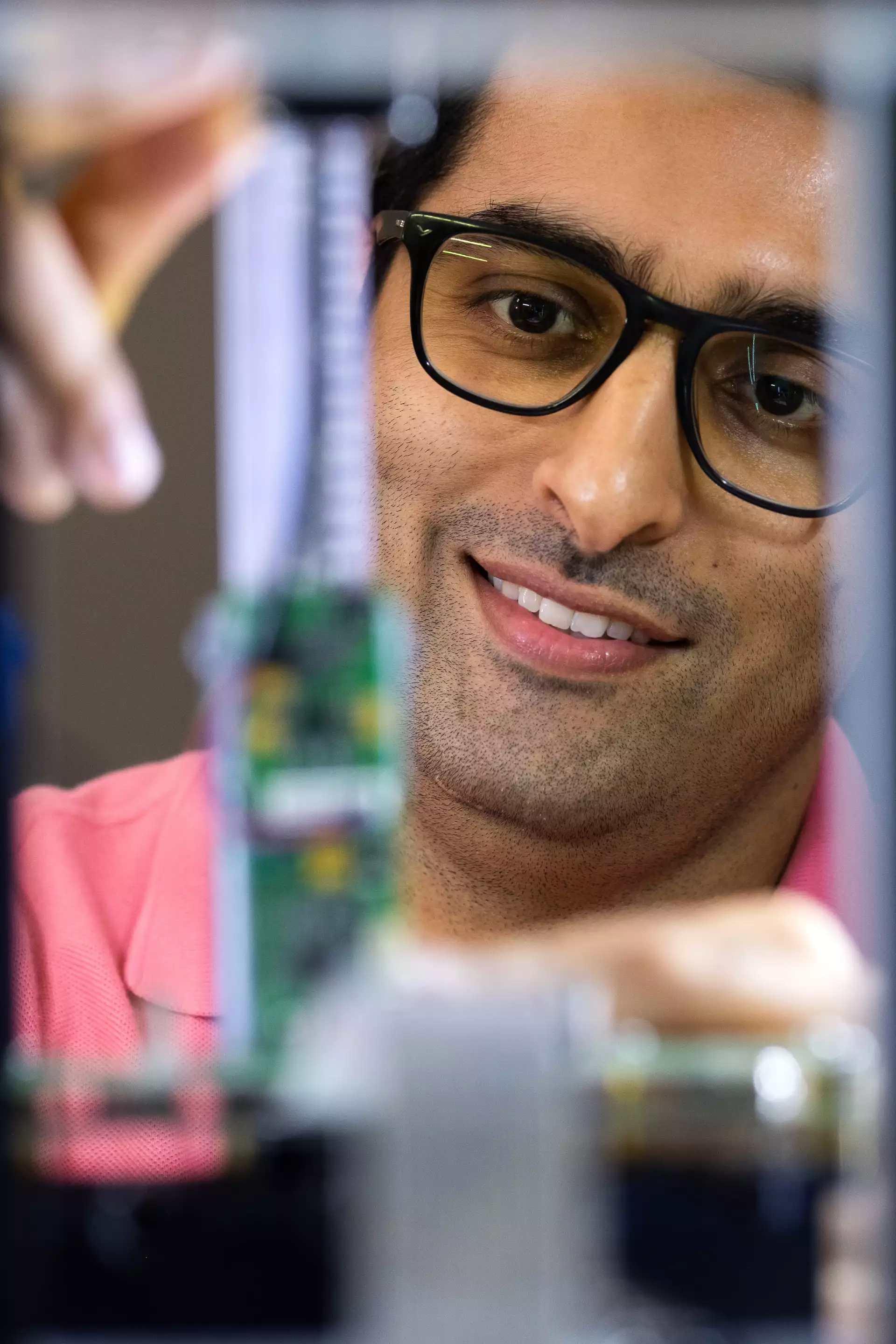

“There are plenty of theoretical systems people cannot synthesize,” says lead author Seyed Mohammad Sajadi. “They’ve remained impractical and elusive. But with 3D printing, we can still take advantage of the predicted mechanical properties because they’re the result of the topology, not the size.”

The engineers at Rice University used the theory behind tubulanes to create different kinds of blocks using computer simulation software, and then 3D-printed polymer versions to see how they performed.

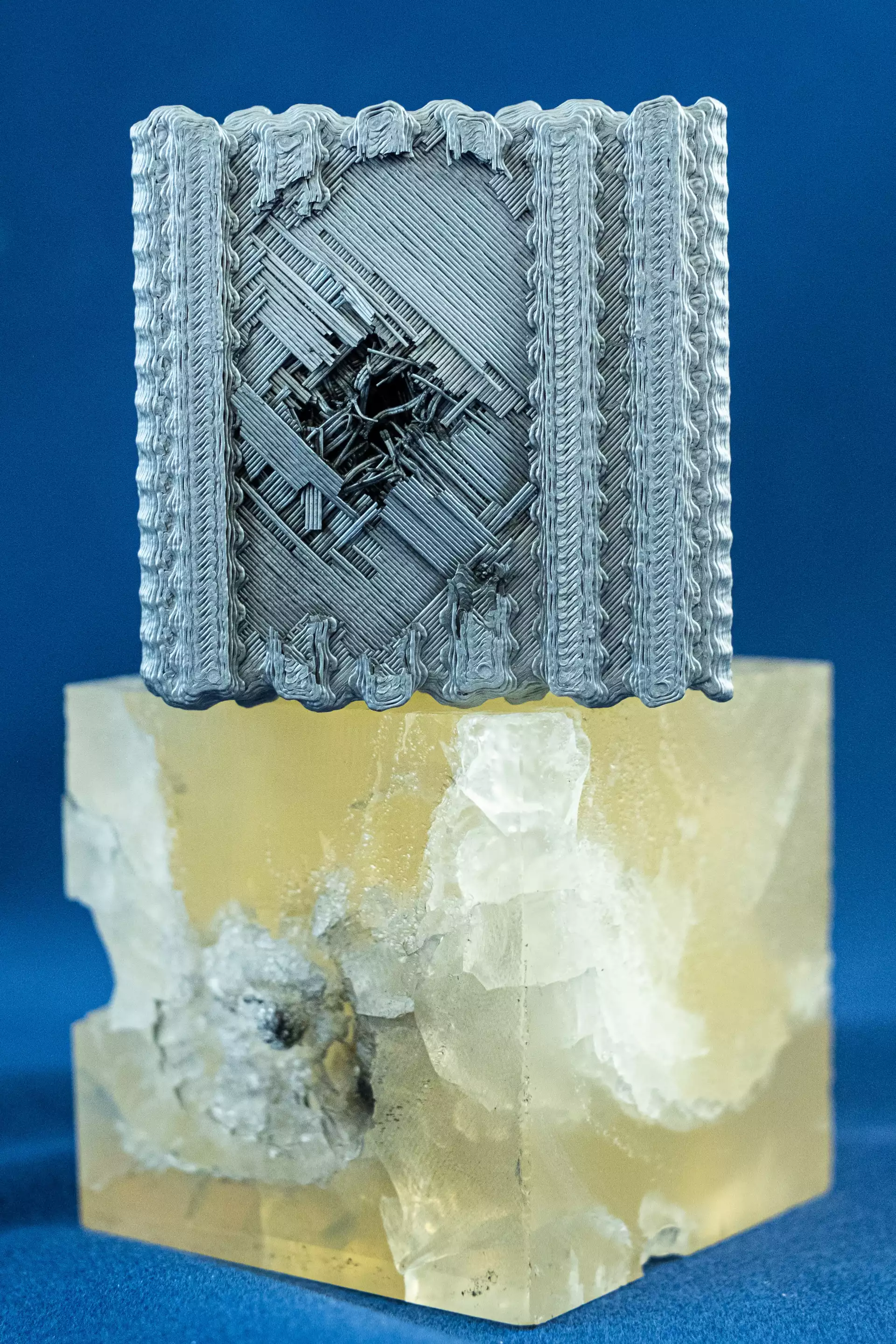

The capabilities of these scaled-up, latticed structures were tested out alongside solid cubes made from the same polymer material, with some impressive results. The team blasted the structures with bullets traveling at 5.8 km (3.6 mi) per second, with the latticed cube proving 10 times more effective at absorbing the impact.

“The bullet was stuck in the second layer of the structure,” says Sajadi. “But in the solid block, cracks propagated through the whole structure.”

The team also subjected the material to crushing pressures beneath a press in the lab, with it again exhibiting some impressive durability. Rather than cracking under the load, the tubulane-inspired blocks tended to collapse on themselves and absorb the pressure.

According to Sajadi, the size of the tubulane-inspired structures is only limited by the size of the 3D printer, and different versions made from metal, ceramic and polymer could find all kinds of uses. The team is working to optimize the design further, with applications in civil engineering, aerospace, oil and gas production among the possibilities.

“The impact resistance of these 3D-printed structures puts them in a class of their own,” says study co-author Peter Boul.

The research was published in the journal Small, while you can see them put the test beneath the laboratory press in the video below.

Source: Rice University