To help combat the rise of antibiotic-resistant bacteria, researchers have been experimenting for years with drug-free methods to blast disease-causing bugs. A new type of stainless steel does exactly that, in a convenient and affordable way.

According to a global survey described in the journal Nature, in 2019 alone, antibiotic-resistant bacteria killed more people than HIV/AIDS or malaria. The superbugs were implicated in nearly five million deaths, directly causing over 1.27 million fatalities. A report from the UN's Environment Programme says that the WHO lists antimicrobial resistance (AMR) as one of the top 10 global threats to health, and that by 2050, up to 10 million additional deaths could be caused by bugs that have evolved to avoid our drugs. That would be on par with the number of global deaths from cancer in 2020.

Understandably concerned about numbers like these, researchers from Georgia Tech set out to attack AMR mechanically instead of chemically. In particular, they sought to combat Gram-negative bacteria such as E. coli, cholera, and salmonella because they contain a protective capsule that makes them particularly good at fighting back against traditional antibiotics.

"Killing Gram-positive bacteria without chemicals is comparatively easy but tackling Gram-negative bacteria poses a significant challenge, due to their thick, multilayered cell membrane," said Anuja Tripathi, the study’s lead author. "And if these bacteria persist on surfaces, they can grow rapidly. I aimed to develop an antibiotic-free bactericidal surface effective against Gram-negative and Gram-positive bacteria."

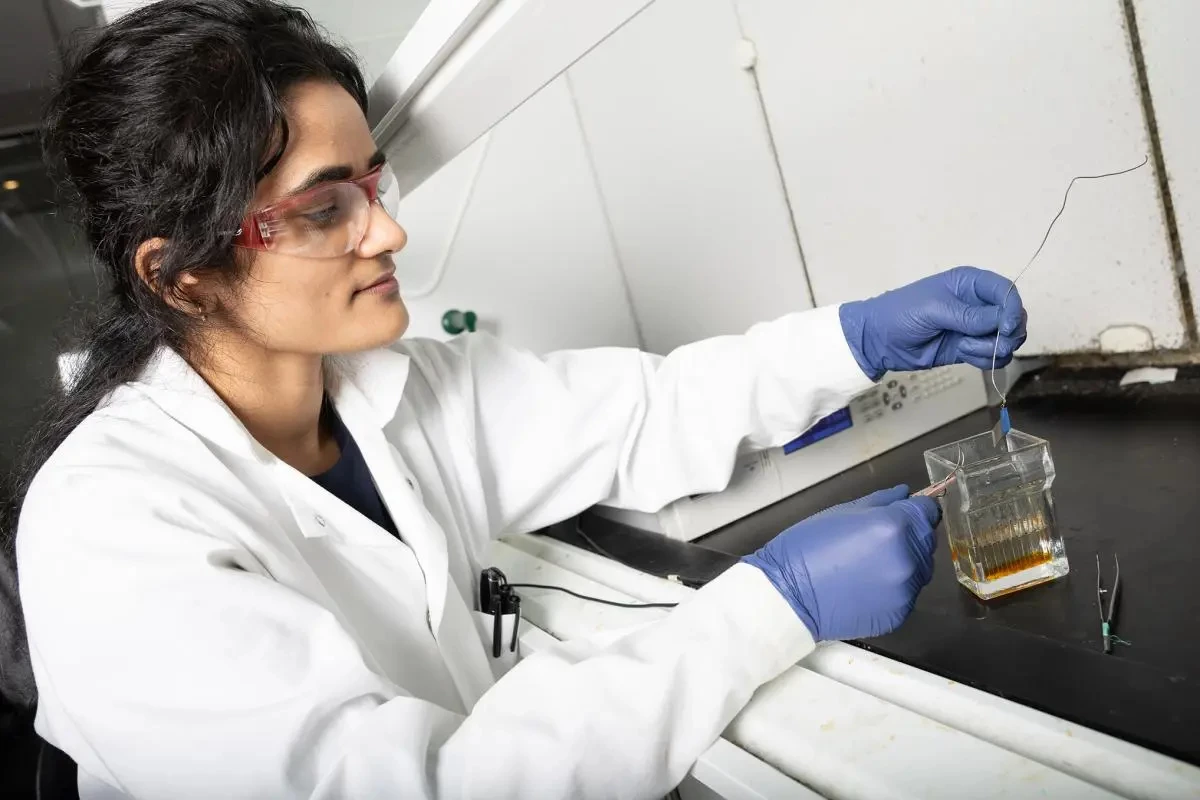

Using an electrochemical process, Tripathi's team etched the surface of stainless steel to create thousands of tiny microspikes. They then bonded copper ions to the surface of the steel, again using electrochemistry. The result is a material that blasts AMR bugs two ways. The spikes shred their protective outer membranes, and the copper – which has been known for its antibacterial qualities since ancient Egyptian times – further degrades their cellular membranes.

In tests, the steel and copper material reduced Gram-negative E. coli by 97% and led to a 99% reduction in Gram-positive Staphylococcus epidermis bacteria. The material was shown to achieve these results in only 30 minutes.

The fact that the new material only contains a very thin layer of copper means it sidesteps the high cost of the material, thus keeping the new steel/copper combo affordable. And because it shreds bacteria with its spikes, it should keep the bugs from evolving the means to escape death, as they can do with chemical treatment methods.

This is not the first time we've seen materials that use mechanical methods to shred resistant bacteria. This year alone, we've reported on a spiky titanium material inspired by dragonfly wings that shreds a common respiratory virus, and spikes on a nanocrystal that spin up under light to dice up bacteria. The Georgia Tech study takes things a step further with the addition of copper and, based on the dire warnings of health agencies regarding AMR, can we really have enough ways to fight the attack of the superbugs?

The research has been published in the journal, Small.

Source: Georgia Tech