The ability to 3D print titanium-alloy objects certainly does open up some intriguing possibilities. That said, the finished items aren't always as strong as they could be. Now, new research suggests that adding copper to those alloys could make a big difference.

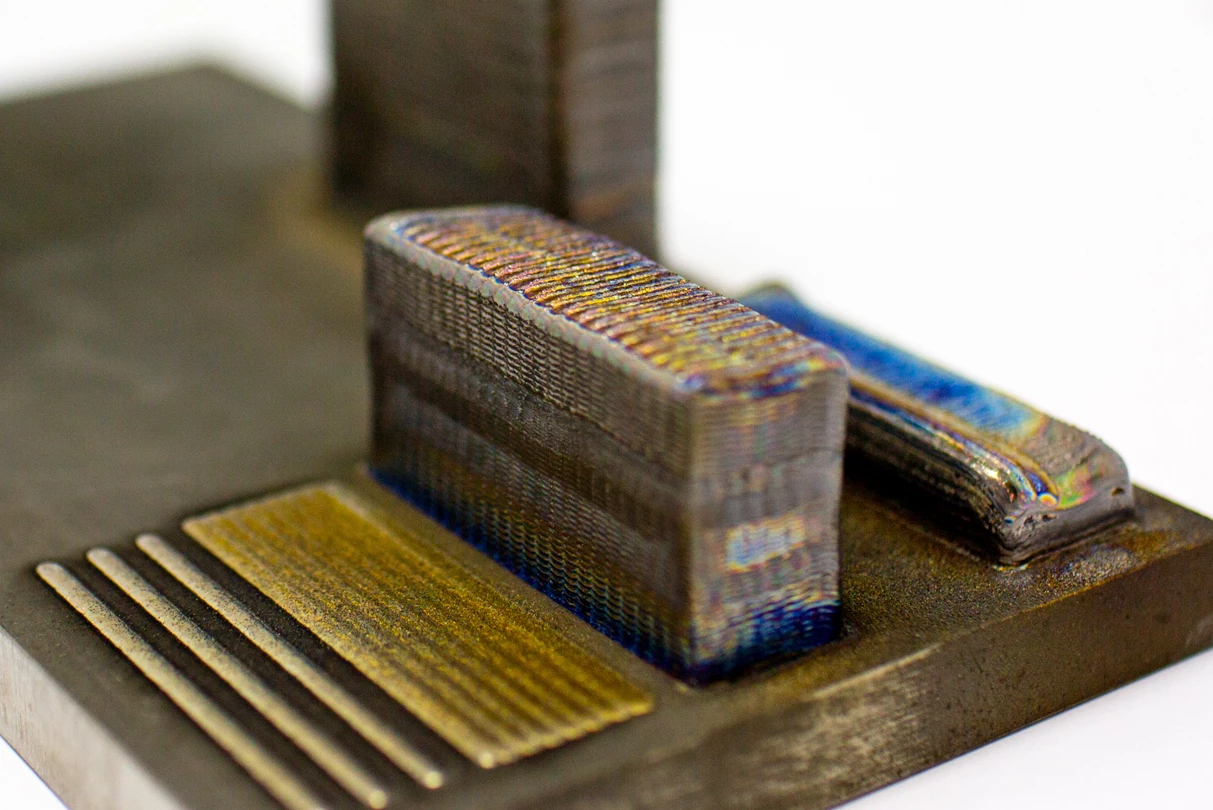

Typically, when objects are being 3D printed out of titanium alloy, a laser is used to selectively melt a powder consisting of titanium particles and other chemical elements. In this fashion, items are built up a layer at a time, as each layer of melted powder cools into a solid.

According to scientists at Australia's RMIT University, however, problematic column-shaped crystals form within the material as it cools and bonds. These ultimately make the end product more prone to cracking and distortion.

And unfortunately – unlike the case with some other metals – there are no commercially-available grain-refining compounds that can be used with titanium alloys, in order to address the problem.

Working with colleagues from CSIRO (the Commonwealth Scientific and Industrial Research Organisation), the University of Queensland and the Ohio State University, RMIT researchers instead looked to copper. More specifically, they experimented with 3D printing objects out of a titanium alloy powder that was mixed with copper powder. The resulting solid material showed great promise.

"Of particular note was its fully equiaxed grain structure: this means the crystal grains had grown equally in all directions to form a strong bond, instead of in columns, which can lead to weak points liable to cracking," says RMIT's Prof. Mark Easton. "Alloys with this microstructure can withstand much higher forces and will be much less likely to have defects, such as cracking or distortion, during manufacture."

It is hoped that once the technology is developed further, such titanium-copper alloys could find use in fields such as medicine, defence and aerospace.

A paper on the study was recently published in the journal Nature.

Source: RMIT