Scientists in Japan working to stretch the limits of super-elastic materials have made a significant breakthrough, demonstrating a new iron-based alloy that endures extremely high and low temperatures. With this ability to be deformed and regain its original shape in all kinds of conditions, the team hopes its new super-elastic metal can find uses in more earthquake-resistant buildings, and possibly even outer space.

Superelastic alloys (SEAs) are a class of materials with supreme elasticity that enables them to be deformed and return to their original shape. Their unique properties have seen these durable materials come to be used in everything from glasses and aprons, to medical and dental applications, but they do have their limitations in their current form.

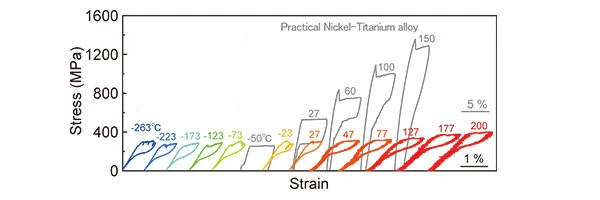

The amount of mechanical force these materials can withstand is influenced by the ambient temperature, with the superelastic alloys used today able to function in temperatures ranging from -20 °C to 80 °C (-4 °F to 173 °F). Made from materials like titanium and nickel, these alloys are also costly, meaning they are mostly used in the form of thin wires and tubes.

A team of engineers at Tohoku University has come up with a new recipe for superelastic alloys that could significantly broaden their potential applications. The new material is made from iron, aluminum, nickel and chromium, and by carefully controlling the concentration of chromium content, the team was able to produce a superelastic alloy that essentially operates independently of the ambient temperature, maintaining its properties in environments of -263 °C right up tp 200 °C (-441 °F to 392 °F).

One of the more exciting potential uses the team sees for its new technology is in space exploration, where materials for vehicle construction need to be able to withstand deformation in the most extreme environments, such as on the Moon or on Mars, where night and day temperatures can fluctuate between -170 °C and 120 °C (-274 °F and 248 °F). It could, however, also find uses much closer to home.

"Yet, the new, SEA's usage does not stop there." says Professor Toshihiro Omori, who led the research team. "It can potentially be used in tension braces in buildings or column elements in bridges – providing greater resistance to earthquakes.”

The research was published in the journal Science.

Source: Tohoku University