Swedish government-owned mining company LKAB has reported the largest deposit of rare earth metals ever discovered in Europe – more than a million tonnes of rare earth oxides, which will be invaluable in the race toward decarbonization.

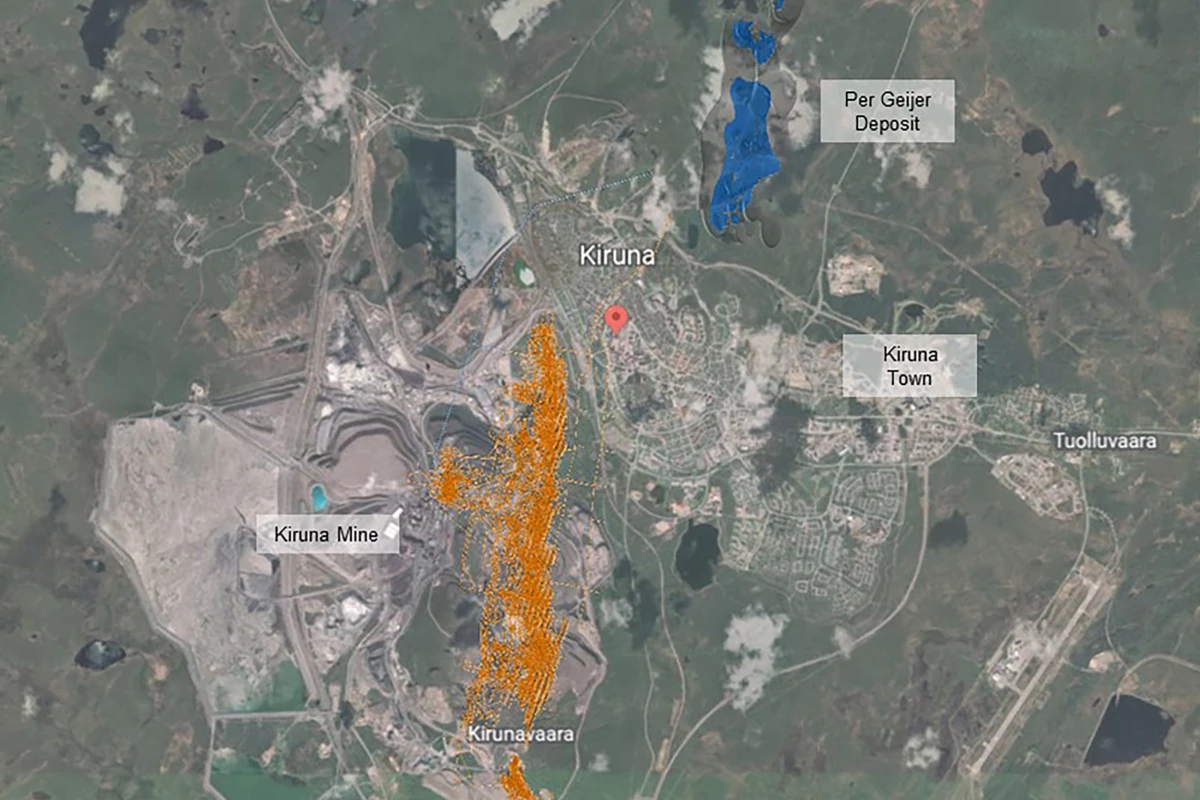

LKAB is racing to investigate the find, known as the Per Geijer deposit, which was discovered adjacent to the company's Kiruna mine in Lapland, which has been described as the largest and most modern underground iron ore mine in the world.

There is currently zero rare earth mining in Europe; the industry is currently absolutely dominated by China, which produces some 61% of the world's rare earth supply according to Mining Technology, with the United States in a distant second place with just 15% of the market.

There are 17 rare earth elements, prized for their outstanding magnetic and conductive qualities, but the most important at the moment is neodymium, which is alloyed with boron and iron to form the world's strongest permanent magnets. These magnets are in high demand as the world moves away from fossil fuels; they're used extensively in electric motors.

Neodymium and the other rare earths are essential for a range of tech products, including smartphones, solar panels, wind turbines and monitors, to name just a few. Mining Technology estimates that every EV battery uses about a kilogram (2.2 lb) of rare earths, and every wind turbine uses about 600 kg (1,323 lb).

As with lithium, demand for these elements is projected to skyrocket over the coming decades, placing China very much in the driver's seat to control the market.

The million-plus-tonne find is the biggest in European history, and LKAB is hoping to begin exploiting it as quickly as possible, but the company says in a press release that the current permitting process would appear to prevent it delivering raw materials to the market for "at least 10-15 years."

To put the find in perspective, the world's largest known rare earths deposit is the Bayan Obo deposit in Inner Mongolia, northern China. It's been in production since 1957 and contains some 40 million tonnes of reserves.

“This is good news, not only for LKAB, the region and the Swedish people, but also for Europe and the climate," says Jan Moström, President and Group CEO, LKAB. "This is the largest known deposit of rare earth elements in our part of the world, and it could become a significant building block for producing the critical raw materials that are absolutely crucial to enable the green transition. We face a supply problem. Without mines, there can be no electric vehicles."

Source: LKAB